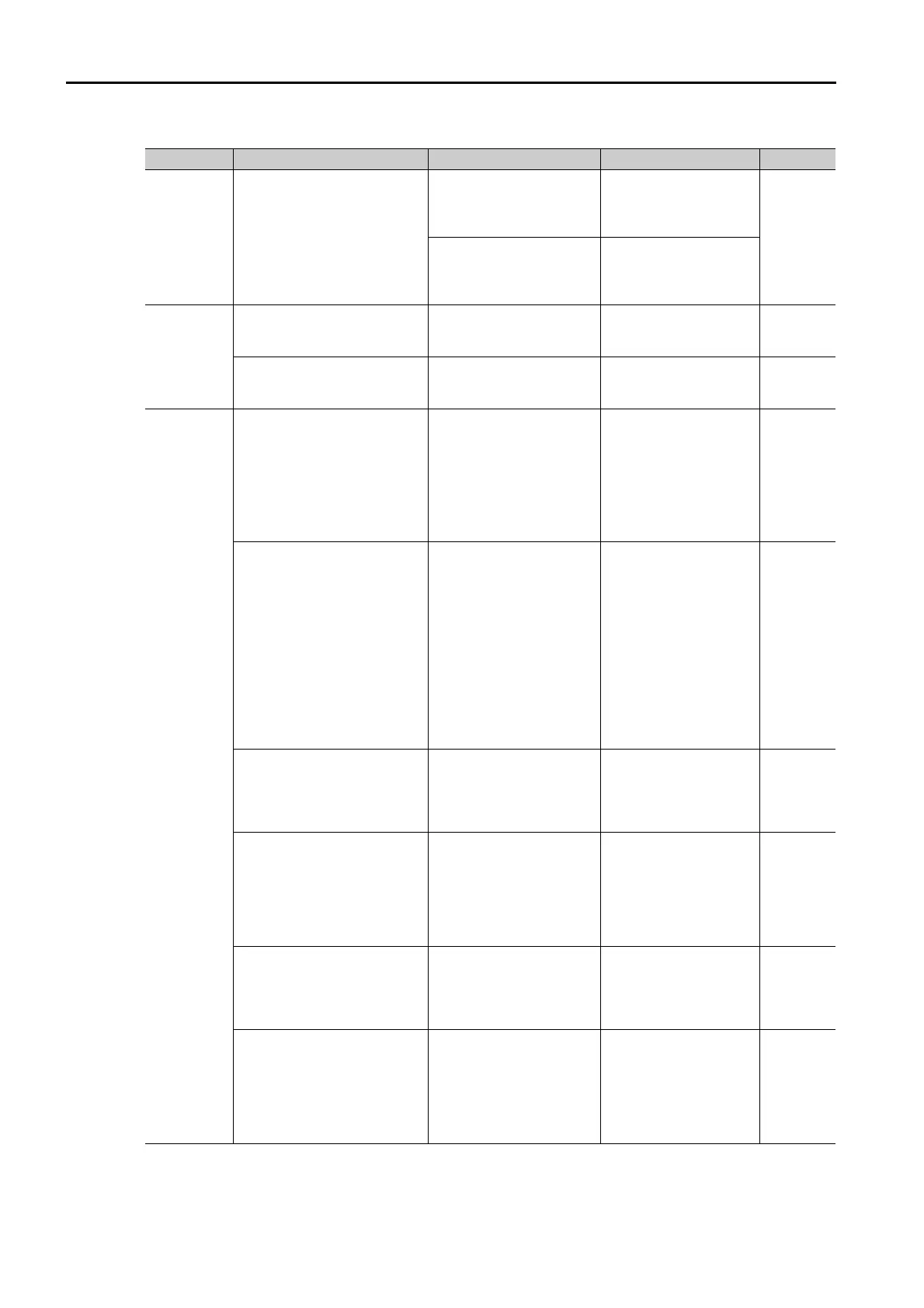

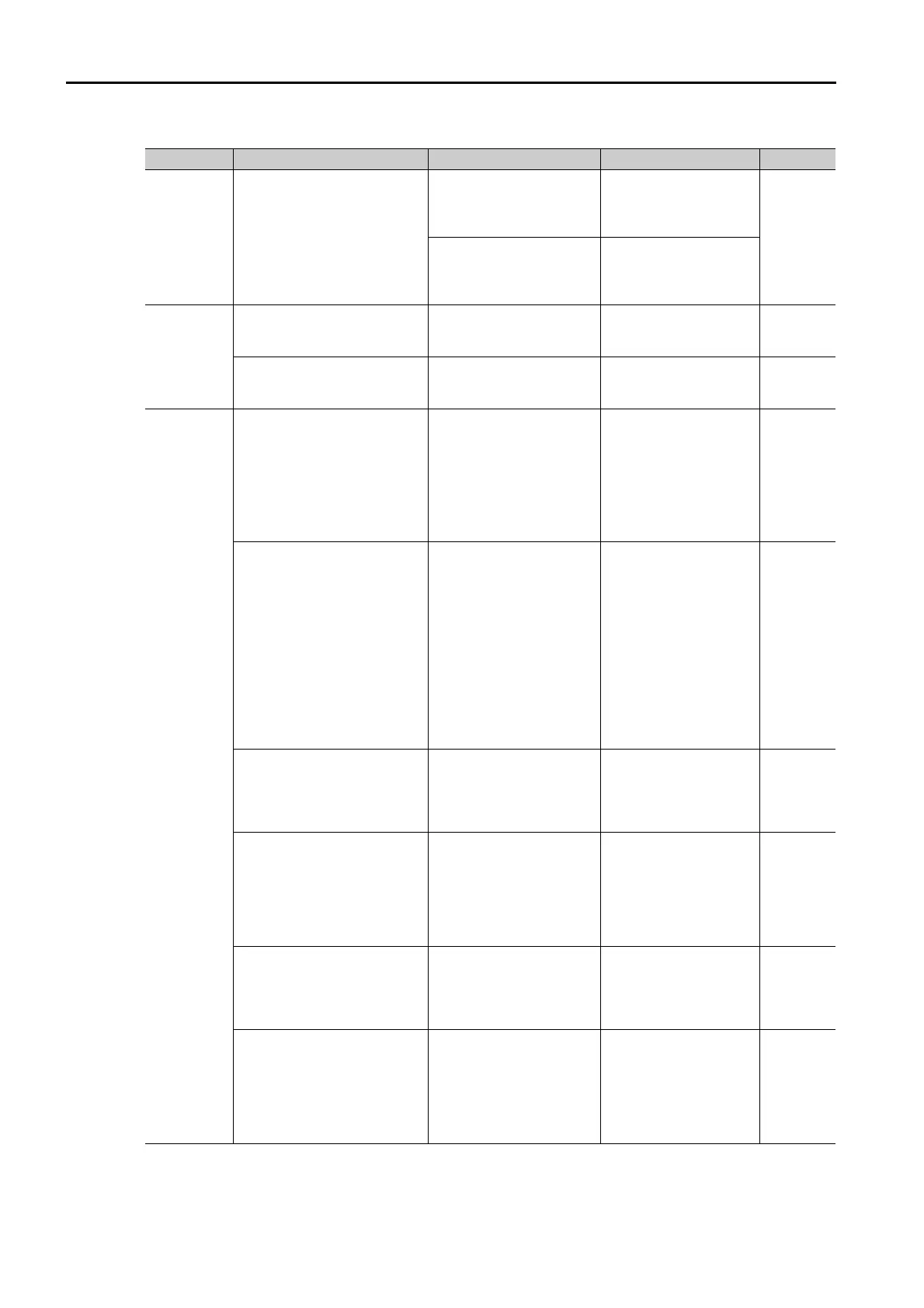

6.3 Troubleshooting Based on the Operation and Conditions of the Servomotor

6-54

Overtravel

Occurred

The selection of the Servo-

motor stopping method is

not correct.

Check the servo OFF

stopping method set in

Pn001 = n.X or

Pn001 = n.X.

Select a Servomotor

stopping method other

than coasting to a stop.

*

Check the torque control

stopping method set in

Pn001 = n.X or

Pn001 = n.X.

Select a Servomotor

stopping method other

than coasting to a stop.

Improper

Stop Posi-

tion for

Overtravel

(OT) Signal

The limit switch position and

dog length are not appropri-

ate.

–

Install the limit switch at

the appropriate posi-

tion.

–

The overtravel limit switch

position is too close for the

coasting distance.

–

Install the overtravel

limit switch at the

appropriate position.

–

Position

Deviation

(without

Alarm)

Noise interference occurred

because of incorrect Encoder

Cable specifications.

Check the Encoder Cable

to see if it satisfies speci-

fications. Use shielded

twisted-pair cables or

screened twisted-pair

cables with conductors of

at least 0.12 mm

2

(stranded wire).

Use cables that satisfy

the specifications.

–

Noise interference occurred

because the Encoder Cable

is too long.

Turn OFF the power sup-

ply to the servo system.

Check the length of the

Encoder Cable.

• Rotary Servomotors:

The Encoder Cable

length must be 50 m

max.

• Linear Servomotors:

Make sure that the

Serial Converter Unit

cable is no longer

than 20 m and that

the Linear Encoder

Cable and the Sensor

Cable are no longer

than 15 m each.

–

Noise interference occurred

because the Encoder Cable

is damaged.

Turn OFF the power sup-

ply to the servo system.

Check the Encoder Cable

to see if it is pinched or

the sheath is damaged.

Replace the Encoder

Cable and correct the

cable installation envi-

ronment.

–

The Encoder Cable was sub-

jected to excessive noise

interference.

Turn OFF the power sup-

ply to the servo system.

Check to see if the

Encoder Cable is bundled

with a high-current line or

installed near a high-cur-

rent line.

Correct the cable lay-

out so that no surge is

applied by high-current

lines.

–

There is variation in the FG

potential because of the

influence of machines on the

Servomotor side, such as a

welder.

Turn OFF the power sup-

ply to the servo system.

Check to see if the

machines are correctly

grounded.

Properly ground the

machines to separate

them from the FG of

the encoder.

–

There is a SERVOPACK

pulse counting error due to

noise.

Turn OFF the power sup-

ply to the servo system.

Check to see if there is

noise interference on the

I/O signal line from the

encoder or Serial Con-

verter Unit.

Implement counter-

measures against noise

for the encoder wiring

or Serial Converter Unit

wiring.

–

Continued on next page.

Continued from previous page.

Problem Possible Cause Confirmation Correction Reference

Loading...

Loading...