6.3 Troubleshooting Based on the Operation and Conditions of the Servomotor

6-55

* For details, refer to the following manual.

Σ-7-Series Σ-7W SERVOPACK with MECHATROLINK-III Communications References Product Manual

(Manual No.: SIEP S800001 29)

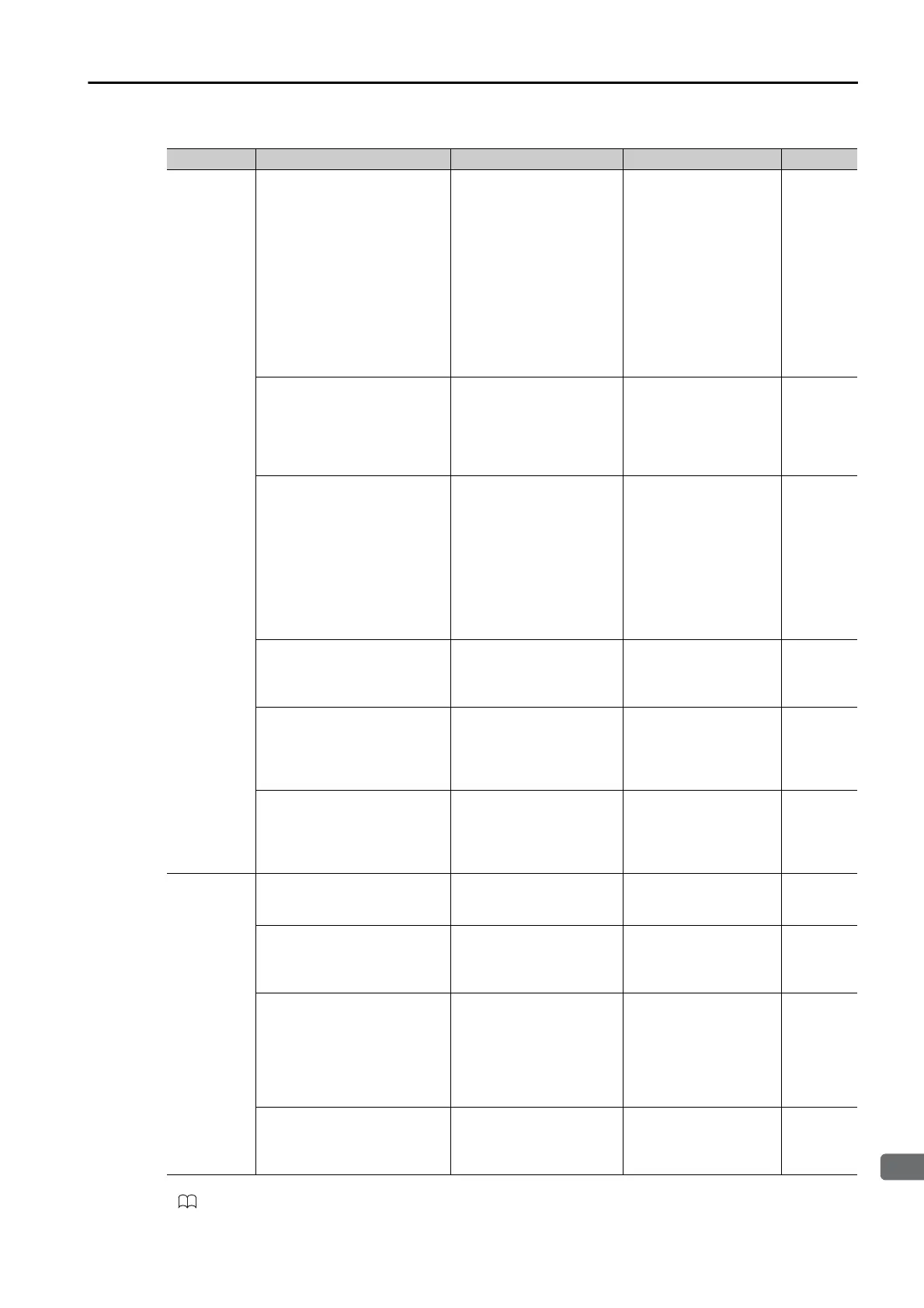

Position

Deviation

(without

Alarm)

The encoder was subjected

to excessive vibration or

shock.

Turn OFF the power sup-

ply to the servo system.

Check to see if vibration

from the machine

occurred.

Check the Servomotor

installation (mounting sur-

face precision, securing

state, and alignment).

Check the linear encoder

installation (mounting sur-

face precision and secur-

ing method).

Reduce machine vibra-

tion. Improve the

mounting state of the

Servomotor or linear

encoder.

–

The coupling between the

machine and Servomotor is

not suitable.

Turn OFF the power sup-

ply to the servo system.

Check to see if position

offset occurs at the cou-

pling between machine

and Servomotor.

Correctly secure the

coupling between the

machine and Servomo-

tor.

–

Noise interference occurred

because of incorrect I/O sig-

nal cable specifications.

Turn OFF the power sup-

ply to the servo system.

Check the I/O signal

cables to see if they sat-

isfy specifications. Use

shielded twisted-pair

cables or screened

twisted-pair cables with

conductors of at least

0.12 mm

2

(stranded wire).

Use cables that satisfy

the specifications.

–

Noise interference occurred

because an I/O signal cable

is too long.

Turn OFF the power sup-

ply to the servo system.

Check the lengths of the

I/O signal cables.

The I/O signal cables

must be no longer than

3 m.

–

An encoder fault occurred.

(The pulse count does not

change.)

–

Turn OFF the power

supply to the servo

system.

Replace the Servomo-

tor or linear encoder.

–

A failure occurred in the

SERVOPACK.

–

Turn OFF the power

supply to the servo

system.

Replace the SERVO-

PACK.

–

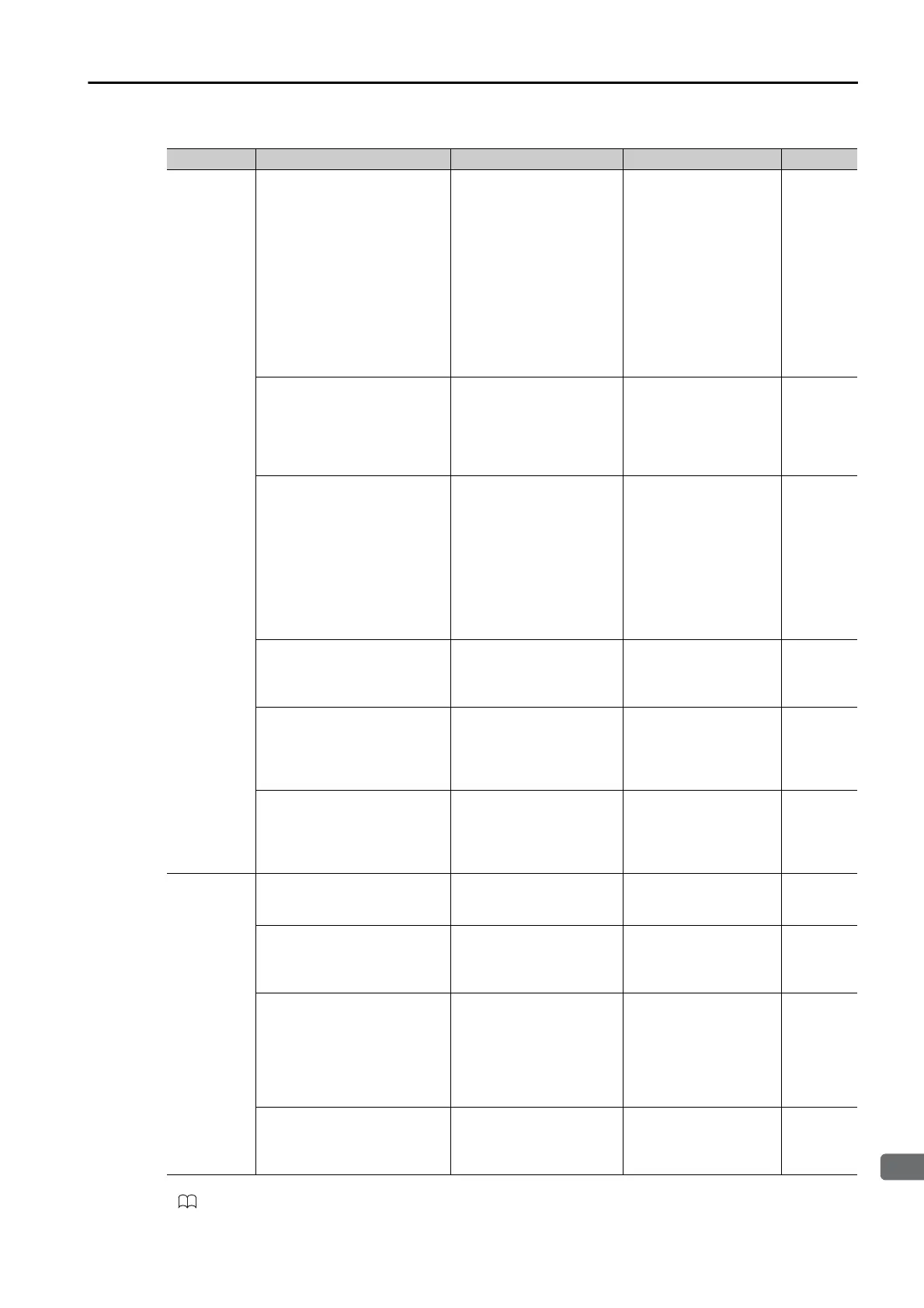

Servomotor

Overheated

The surrounding air tempera-

ture is too high.

Measure the surrounding

air temperature around

the Servomotor.

Reduce the surround-

ing air temperature to

40°C or less.

–

The surface of the Servomo-

tor is dirty.

Turn OFF the power sup-

ply to the servo system.

Visually check the surface

for dirt.

Clean dirt, dust, and oil

from the surface.

–

There is an overload on the

Servomotor.

Check the load status

with a monitor.

If the Servomotor is

overloaded, reduce the

load or replace the

Servo Drive with a

SERVOPACK and Ser-

vomotor with larger

capacities.

–

Polarity detection was not

performed correctly.

Check to see if electrical

angle 2 (electrical angle

from polarity origin) at any

position is between ±10°.

Correct the settings for

the polarity detection-

related parameters.

–

Continued from previous page.

Problem Possible Cause Confirmation Correction Reference

Loading...

Loading...