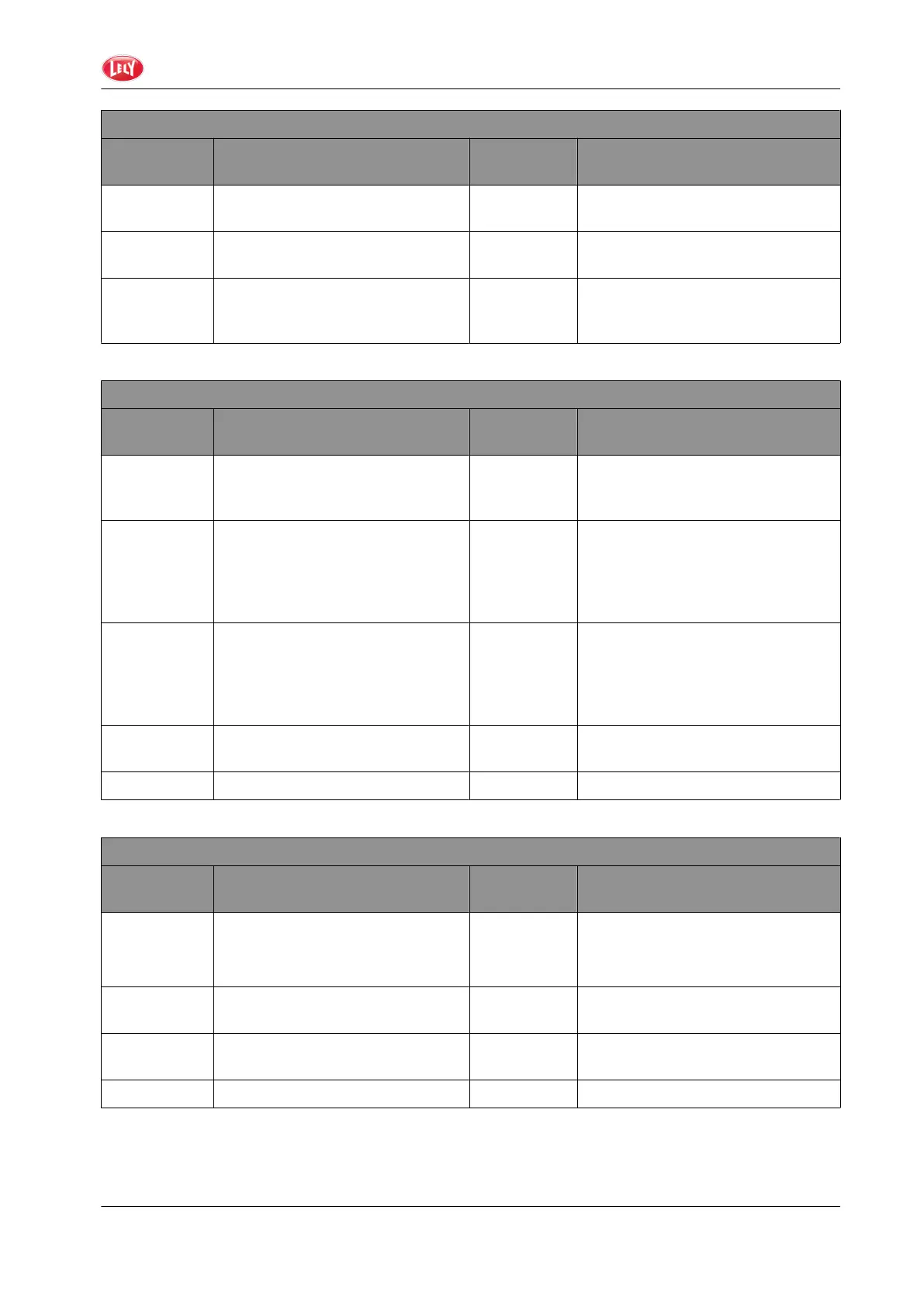

After each 500 bales (or daily)

Position in

figure

Machine part Lubrication Note

3 Two grease nipples on the linkage

point of the wrapping table rollers.

(A) On the two sides of the machine.

4 Grease nipple of the bale transfer. (A) On the left hand side of the

machine.

2 Two grease nipples on the linkage

point of the wrapping table

cylinder.

(A) On the two sides of the machine.

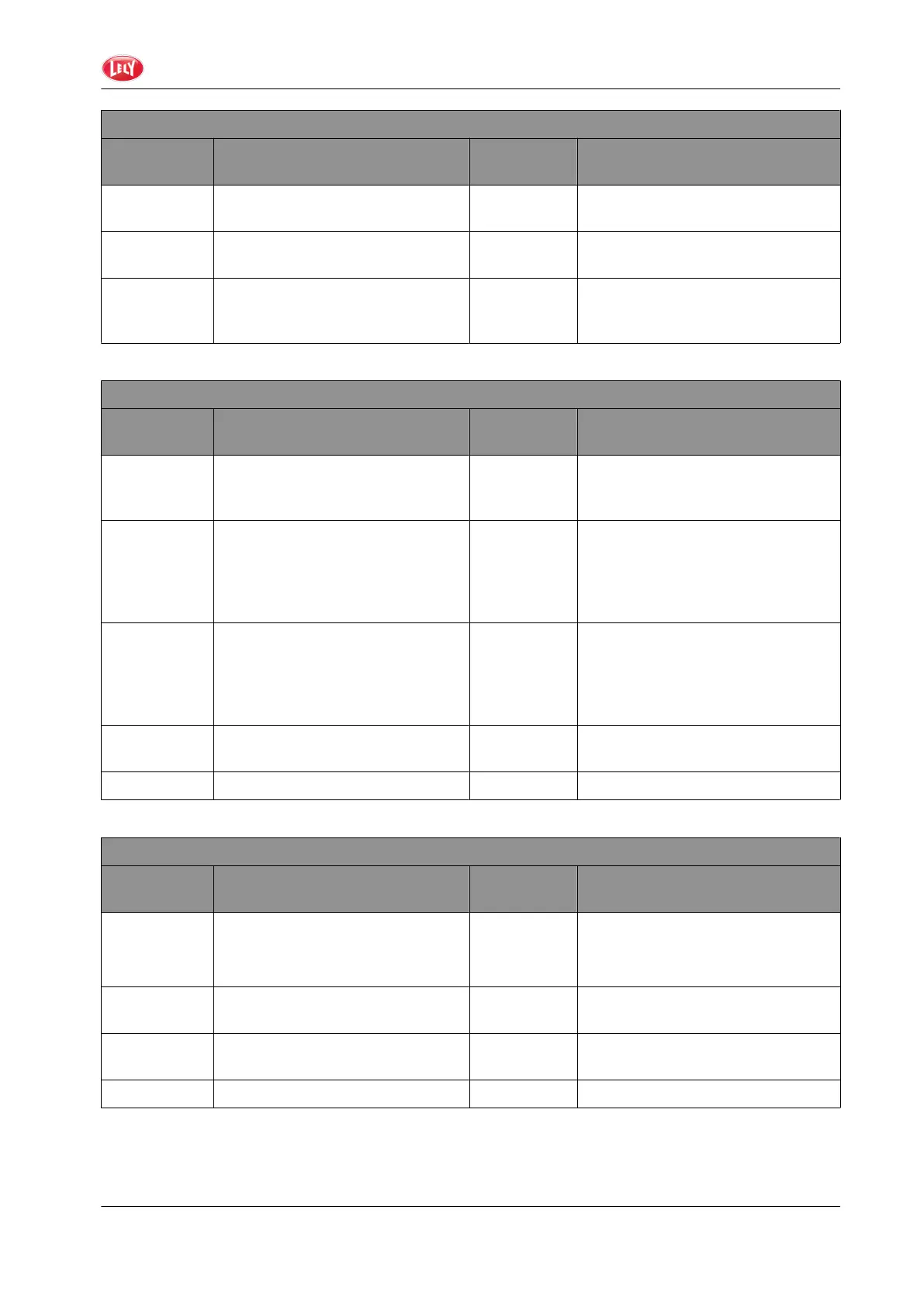

After 3000 bales and before or after the machine is not used for more than 6 weeks

Position in

figure

Machine part Lubrication Note

8 Top belt roller. (A)

On the two sides of the machine,

open the tailgate 1/4 and make sure

that it does not move (RPC 160 V).

8 Central belt rocker roller. (A)

On the two sides of the machine

bring the belt tensioner in to the

service position, open the tailgate

1/4 and make sure that it does not

move (RPC 160 V).

7 Bottom belt rocker roller. (A)

On the two sides of the machine

bring the belt tensioner in to the

service position, open the tailgate

1/4 and make sure that it does not

move (RPC 160 V).

5

Joint between the belt rocker and

the hydraulic cylinder.

(A)

On the two sides of the machine

(RPC 160 V).

1 Drive train of the wrapping table. (A) On the right side of machine.

At the end of the season annually (in case of special operating conditions also weekly)

Position in

figure

Machine part Lubrication Note

13 Main gear unit. (C) (2.2L)

Oil change.

Check the filling level with a dip stick

or overflow hole.

12 Movable parts of net tying unit. (D) To make sure that there is a smooth

movement.

9 Hydraulic cylinder on the tailgate

locking mechanism.

(A) On the two sides of the machine.

11 Star ratchet in the pick-up drive. (A) On the left side of the machine.

4

4. Maintenance and Lubrication

Baler Wrapper Combination 117

4900.LE.EN01

Loading...

Loading...