i2000SR interface module Service Manual

Page 16 of 212 625798100.APS.5.doc

into an empty carrier at this time. When the LED is green, tubes

can be manually loaded into the carrier located at this gate.

Gate 7a – (G7a) is on Lane 2 and is operated by electro valve

EV10. This Type 1 gate stops the carrier on Lane 2 to avoid a

collision with a carrier that is being introduced from the Lane 3

Routine Manual input area gate (G7b). The Routine Manual Input

samples from Lane 3 have precedence over carriers running on

Lane 2. The opening of the diverter D1 (Lane 3/2 Diverter) drives

the closing of Gate 7a and prevents collisions as a new tube

carrier enters from the manual input gate. (See Gate 7b).

Gate 8 (G8) – is the Priority Input Gate located on Lane 3 and is

operated by electro valve EV16. This Type 2 gate is located at the

Priority Manual Input position and is controlled by an optical tube

sensor located at the entry position. The sensor is used to verify

the presence of a tube in the carrier. The Priority Input position is

used to insert priority samples, calibrators and controls. The

carrier will be introduced onto the large disk and routed via the

pair of D2 diverters to Lane 1. The D2 diverters are the Lane 3/1

and Lane 2/1 Diverters and are operated by electro valve EV4.

The Lane 3/1 Diverter is positioned to prevent the carrier from

being routed to the Main APS track. The Lane 2/1 Diverter opens

to allow the carrier to enter Lane 1.

NOTE:

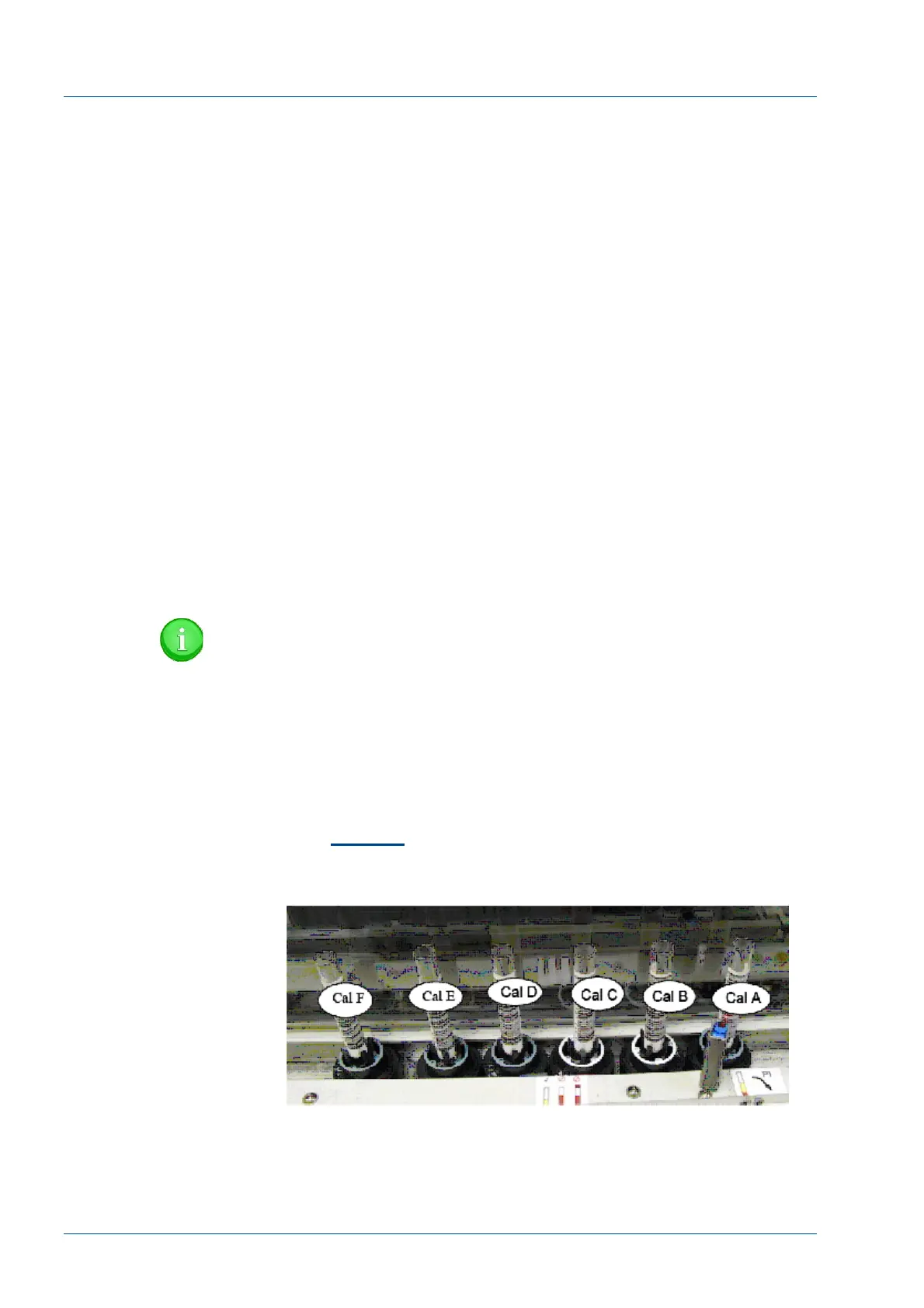

When introducing calibrators and other tubes that need to

be processed according to a specific order, they must be

loaded in order at the Priority Input queue. The last

calibrator to be processed is placed into the appropriate

carrier to the left of the entry point. For a six (6)-point

calibration, the last calibrator “F” is loaded into sixth

carrier to the left. The remaining calibrators are loaded in

sequence as illustrated below. The first calibrator to be

aspirated is “A” and is loaded at the Priority Entry point.

(See

Figure 5

) When the first tube is detected the entire

set of tubes will move in to be processed.

Figure 5 – Calibrator Load (Six point)

Gate 9 (G9) – This Type 1 gate is located on the APS main track

and is operated by electro valve EV17. An optical sensor is

positioned to detect that the On-line carrier was routed from the

large disk and was returned to the main track. The optical carrier

Loading...

Loading...