Service Manual i2000SR interface module

625798100.APS.5.doc Page 191 of 212

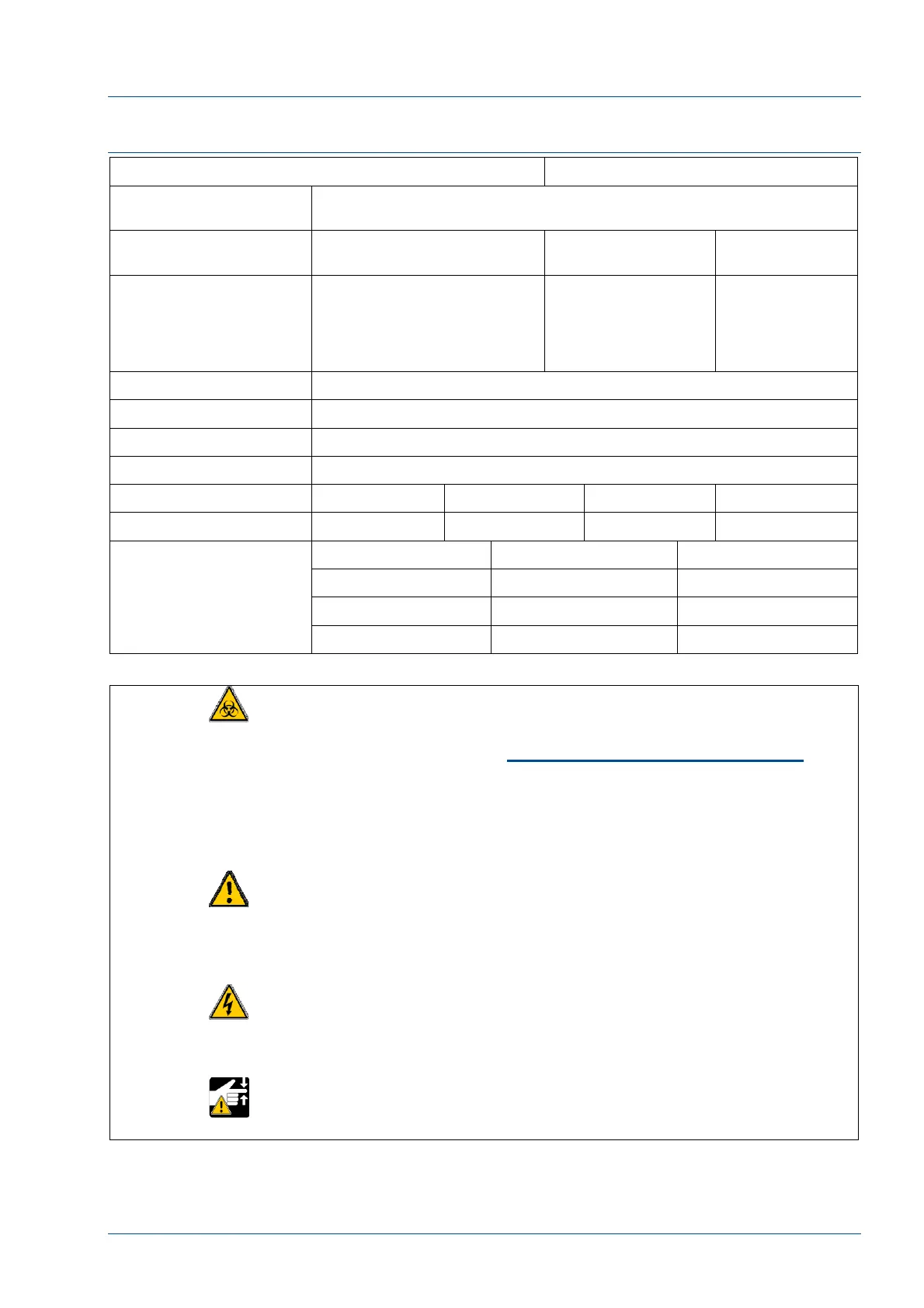

Verification of belt tensioning

ALIGNMENT PROCEDURE SCHEDULE no. 19

Operation:

Belt tensioning verification

Working area: i2000SR IM Mechanical Group: 625.102.00X

Electrical Group: 625.800.00X Part no.

PFD0304

PFD0302

PFD0301

PFD0303

Machine Status: Controlled shutdown and power disconnected

Skill Required: FSE (Field Service Engineer)

Time Required: TBD (To Be Determined)

Special Tools Required: 475.110.190 (8-203930-01) Belt Tension Tool (weight + hook)

Activity Type: ; Setting ; Control Cleaning ; Replacement

Intervention kind: Electrical ; Mechanical Fluidic Pneumatic

Daily Weekly Monthly

Quarterly Half yearly Yearly

Two-year After signalizing ; Because of failure

Frequency:

; When necessary

WARNING: Potential Biohazard. This is an activity or area

where you may be exposed to potentially infectious

material. Refer to “Section 4 - Hazards and Warnings

” of

the Accelerator Service Manual

Reduce exposure by using proper personal protection

equipment and cleaning surfaces with 0.1% sodium

hypochlorite (bleach).

CAUTION: Moving Parts

The safety cover protection is not guaranteed if the

security devices are removed or bypassed. Use caution to

prevent injury caused by moving parts.

WARNING: Electrical Shock Hazard. Possibility of electrical

shock exists if procedural or engineering controls are not

observed.

WARNING: Pinch hazard

Loading...

Loading...