i2000SR interface module Service Manual

Page 28 of 212 625798100.APS.5.doc

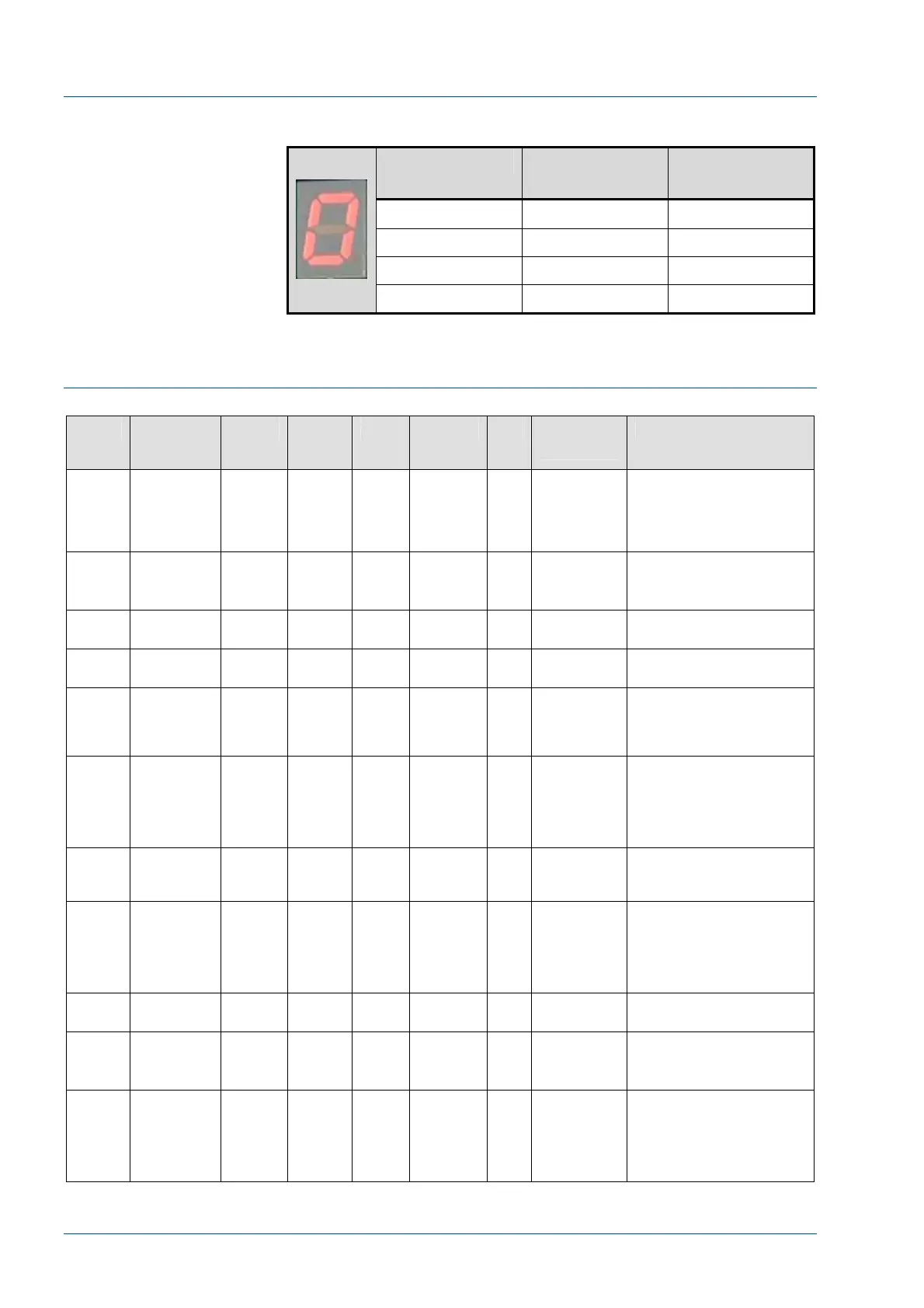

MASTER CAN Board Segment Indicator

LED Indicator Carrier at G3

STAT Probe

Carrier at G4

Sample Probe

0

1 Yes

2 Yes

3 Yes Yes

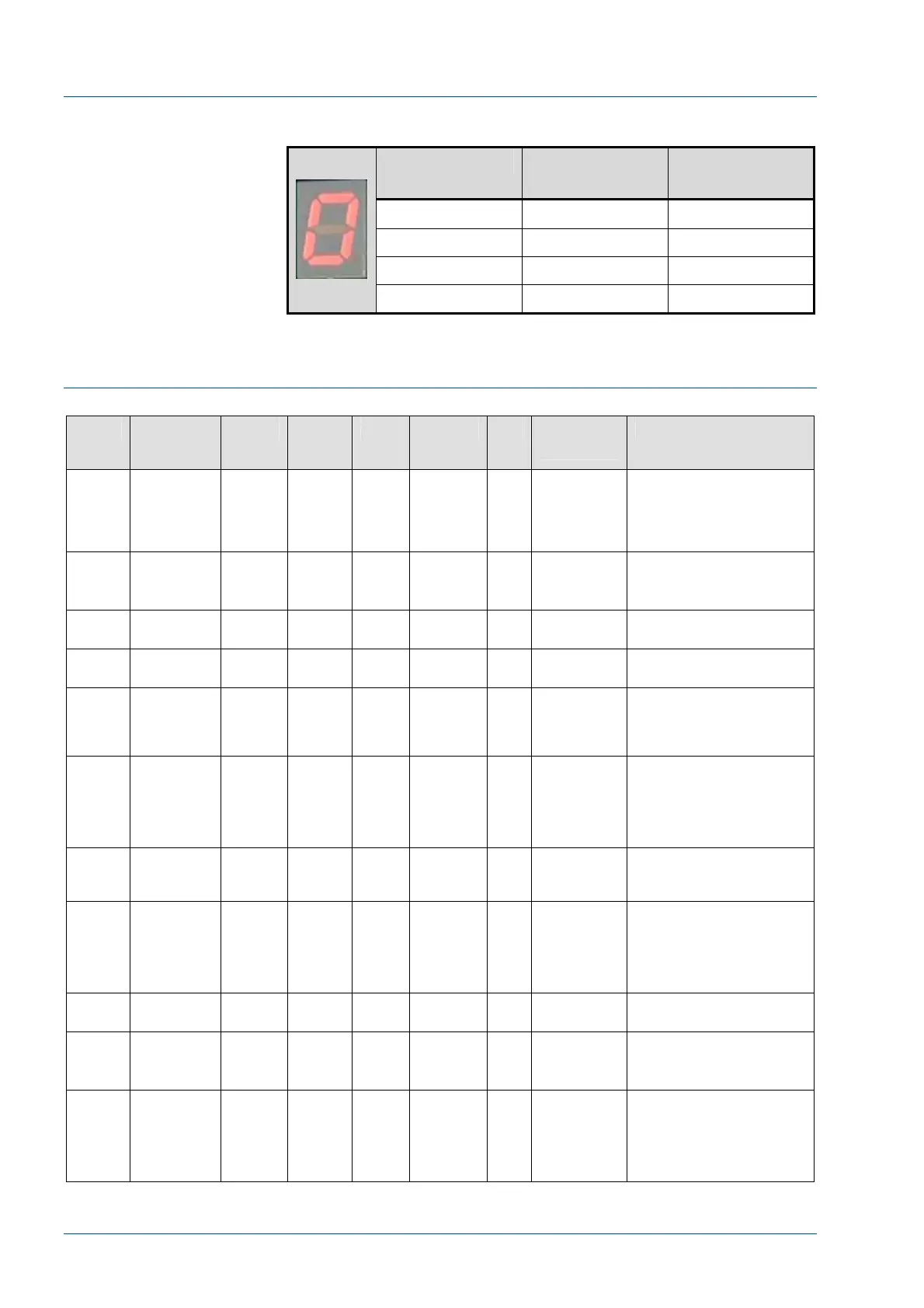

SLAVE 0 CAN Board Description

Table 3 – Slave 0 CAN Board Inputs - Outputs

Pin Function Device Electr

o

Valve

Port Antenna LED Control

Command

Description

Out – 1 Instrument

Gate

G0 EV1 A A0 1 Divert Gate

- Pass

(Pass A)

Activated to either pass a

carrier along the main

track or in conjunction with

diverter D0 route it to IM

entry

Out – 2 Pit stop D0 EV2 A & B Divert Gate

- Pit Stop

(Pit Stop)

Activated to divert a

carrier into the IM entry

Out – 3 Gate at

BCR

G2a EV5 B A2 2 BCR Pass Activated to pass a carrier

at the BCR reader.

Out – 4 Lock Gate

at BCR

G2b EV6 B BCR Lock Activated to lock carrier at

BCR to cause it to spin.

Out – 5 Gate before

BCR

G2c EV7 A Activated to prevent next

carrier from impacting the

spinning of a carrier at the

BCR.

Out – 6 Routine

Tube

Insertion

Green LED

Diag – Bit

13 (Routine

Green LED)

1 = ON

0 = OFF

Activated to indicate that

the condition is correct to

insert tube at routine

location

Out – 7 Entry gate G1 EV3 A A1 4 Pass

Entry Pass

Activated to release

carriers from the IM entry

to Lane 1

Out – 8 Routine

Tube

Insertion

Yellow LED

Diag – Bit

15 (Routine

Yellow LED)

1 = ON

0 = OFF

Activated to indicate that

the conditions are not

correct to insert tube at

routine location

In – 1

to 7

Not Used Not Used

Expans

ion

Out –1

LUI – Pause

button LED

Keypad

Keypad – Pause LED

illuminated

Expans

ion Out

– 2

Post Lamp

– Yellow

K4 Diag – Bit 3

(Yellow

Lamp)

1 = ON

0 = OFF

Activates relay K4 to turn

on the Yellow lamp

(indicate non operational

status that requires

operator attention)

Loading...

Loading...