i2000SR interface module Service Manual

Page 176 of 212 625798100.APS.5.doc

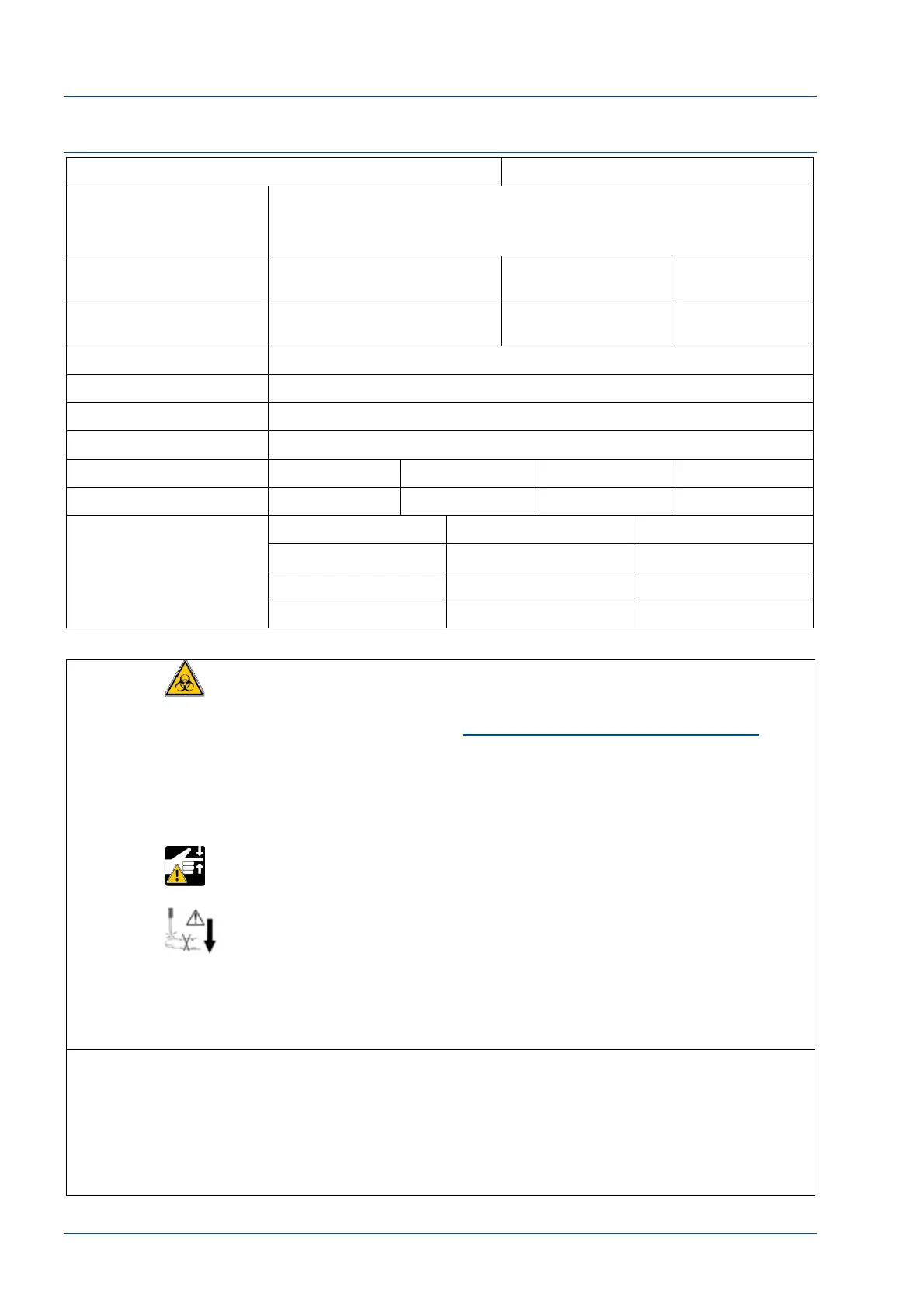

Alignment of routine and STAT sampling gates

ALIGNMENT PROCEDURE SCHEDULE no. 16

Operation:

Routine and STAT Sampling gates

alignment

Working area: i2000SR IM Mechanical Group: 625.102.00X

Electrical Group: 625.800.00X Part no. 515.405.00X

Machine Status: Operating in standalone mode

Skill Required: FSE (Field Service Engineer)

Time Required: TBD (To Be Determined)

Special Tools Required: 475.110.031 (oversized carrier tool)

Activity Type: ; Setting Control Cleaning Replacement

Intervention kind: Electrical ; Mechanical Fluidic Pneumatic

Daily Weekly Monthly

Quarterly Half yearly Yearly

Two-year After signalizing Because of failure

Frequency:

; When necessary

WARNING: Potential Biohazard. This is an activity or area

where you may be exposed to potentially infectious

material. Refer to “Section 4 - Hazards and Warnings

” of

the Accelerator Service Manual

Reduce exposure by using proper personal protection

equipment and cleaning surfaces with 0.1% sodium

hypochlorite (bleach).

WARNING: Pinch hazard

WARNING: Probe Sharps Hazard

Follow safe sharp practices. Do not place your hand near

the probe while it is moving. Put the instrument through a

decontamination cycle and wipe the probe with a

disinfectant prior to touching or working near the probe.

GOAL:

During sample aspiration, the sample and STAT probes

must only touch the fluid at the bottom of the tube.

During the z-axis travel the probe must stay centered on

the tube. Adjust the probe(s), gate(s), antenna, analyzer

feet, and support bracket as required to center the probe

at both the upper and lower positions.

Loading...

Loading...