i2000SR interface module Service Manual

Page 50 of 212 625798100.APS.5.doc

• Refer to the pneumatic drawing provided with the

workcell. As an aid, each pneumatic tube is identified with a label

on each end of the tube that corresponds to the appropriate

device.

Initial i2000SR Support Procedure

NOTE:

Before moving to the track position, ensure that the

i2000SR support bracket is fully seated (down) into the

front panel pockets. If the bracket is mounted too high, the

ability to aspirate the minimum sample volume will be

impacted.

• Check the tension of the i2000SR IM belts.

NOTE:

As the belt tension procedure will hang a weight on the

belts, it is recommended that an assistant support the IM

during the procedure.

• Remove the metal screws used to secure the i2000SR IM

to the workcell and replace them with the plastic screws supplied.

These plastic screws are required to ensure that in the event of

seismic activity (earthquake), the analyzer will not cause damage

to the workcell.

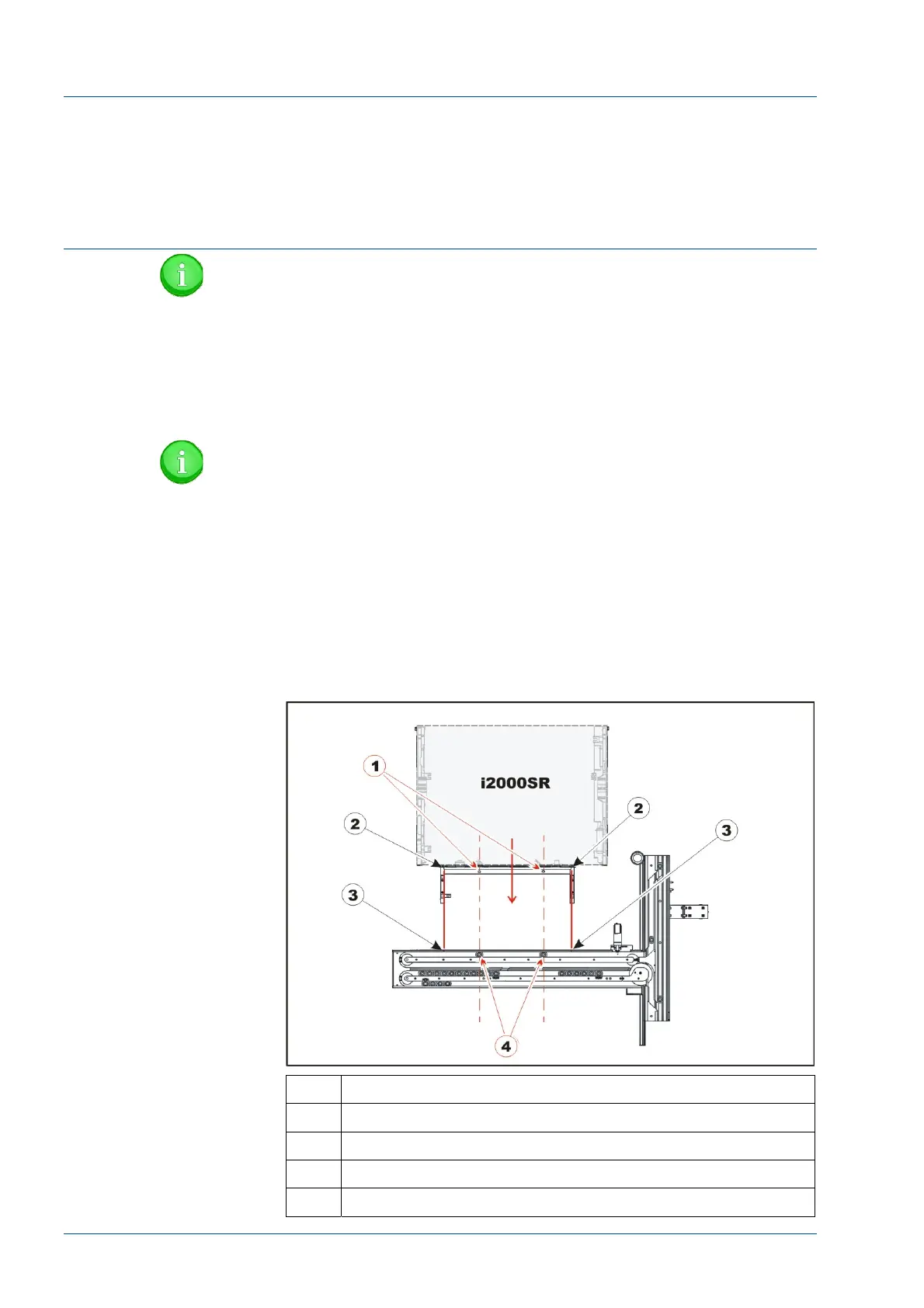

Figure 27 – Positioning i2000SR instrument

No. Description

1 i2000SR sample points

2 i2000SR insert spur rail cut-off

3 i2000SR IM assembly cut-out extreme limits

4 Carriers at sampling stop gate points

Loading...

Loading...