2-6

Valve/Tappet

Clearance

(Feeler Gauge Procedure)

To check and adjust valve/tappet clearance, use the

following procedure.

NOTE: The engine must be cold for this proce-

dure.

NOTE: The seats, center console, spark plug,

and air filter housing must be removed for this pro-

cedure.

1. Remove the timing inspection plug; then remove

the tappet covers (for more detailed information,

see Section 3 - Servicing Top-Side Components).

2. Rotate the crankshaft to the TDC position on the

compression stroke.

NOTE: At this point, the rocker arms and

adjuster screws must not have pressure on them.

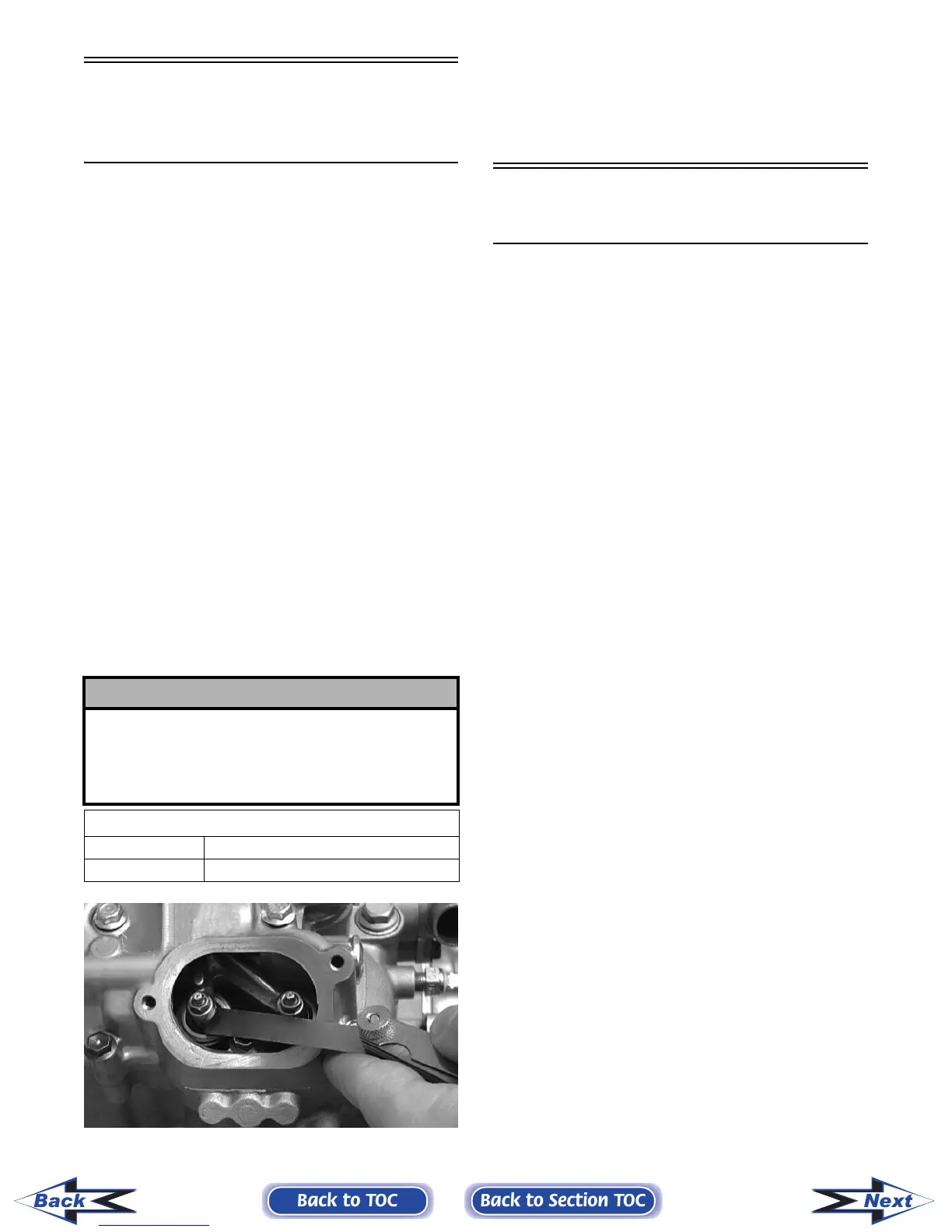

3. Using a feeler gauge, check each valve/tappet

clearance. If clearance is not within specifica-

tions, loosen the jam nut and rotate the tappet

adjuster screw until the clearance is within spec-

ifications. Tighten each jam nut securely after

completing the adjustment.

CC007D

4. Install the spark plug; then install the timing

inspection plug.

5. Place the two tappet covers with O-rings into

position. Tighten the cap screws securely.

Valve/Tappet Clearance

(Valve Adjuster Procedure)

To check and adjust valve/tappet clearance, use the

following procedure.

NOTE: The engine must be cold for this proce-

dure.

NOTE: The seats, center console, spark plug,

and air filter housing must be removed for this pro-

cedure.

1. Remove the timing inspection plug; then

remove the tappet covers (for more detailed

information, see Section 3 - Servicing Top-Side

Components).

2. Rotate the crankshaft to the TDC position on the

compression stroke.

NOTE: At this point, the rocker arms and

adjuster screws must not have pressure on them.

NOTE: Use Valve Clearance Adjuster (p/n

0444-078) for this procedure.

3. Place the valve adjuster onto the jam nut secur-

ing the tappet adjuster screw; then rotate the

valve adjuster dial clockwise until the end is

seated in the tappet adjuster screw.

4. While holding the valve adjuster dial in place,

use the valve adjuster handle and loosen the jam

nut; then rotate the tappet adjuster screw clock-

wise until friction is felt.

5. Align the valve adjuster handle with one of the

marks on the valve adjuster dial.

6. While holding the valve adjuster handle in

place, rotate the valve adjuster dial counter-

clockwise until proper valve/tappet clearance is

attained.

NOTE: Refer to the appropriate specifications in

Feeler Gauge Procedure sub-section for the proper

valve/tappet clearance.

NOTE: Rotating the valve adjuster dial counter-

clockwise will open the valve/tappet clearance by

0.05 mm (0.002 in.) per mark.

! CAUTION

The feeler gauge must be positioned at the same

angle as the valve and valve adjuster for an accurate

measurement of clearance. Failure to measure the

valve clearance accurately could cause valve com-

ponent damage.

VALVE/TAPPET CLEARANCE

Intake 0.1016 mm (0.004 in.)

Exhaust 0.1524 mm (0.006 in.)

Back to TOC

Back to Section TOC

Next

Back

FOR ARCTIC CAT ATV DISCOUNT PARTS CALL 606-678-9623 OR 606-561-4983

www.mymowerparts.com

Loading...

Loading...