3-33

3

CD052A

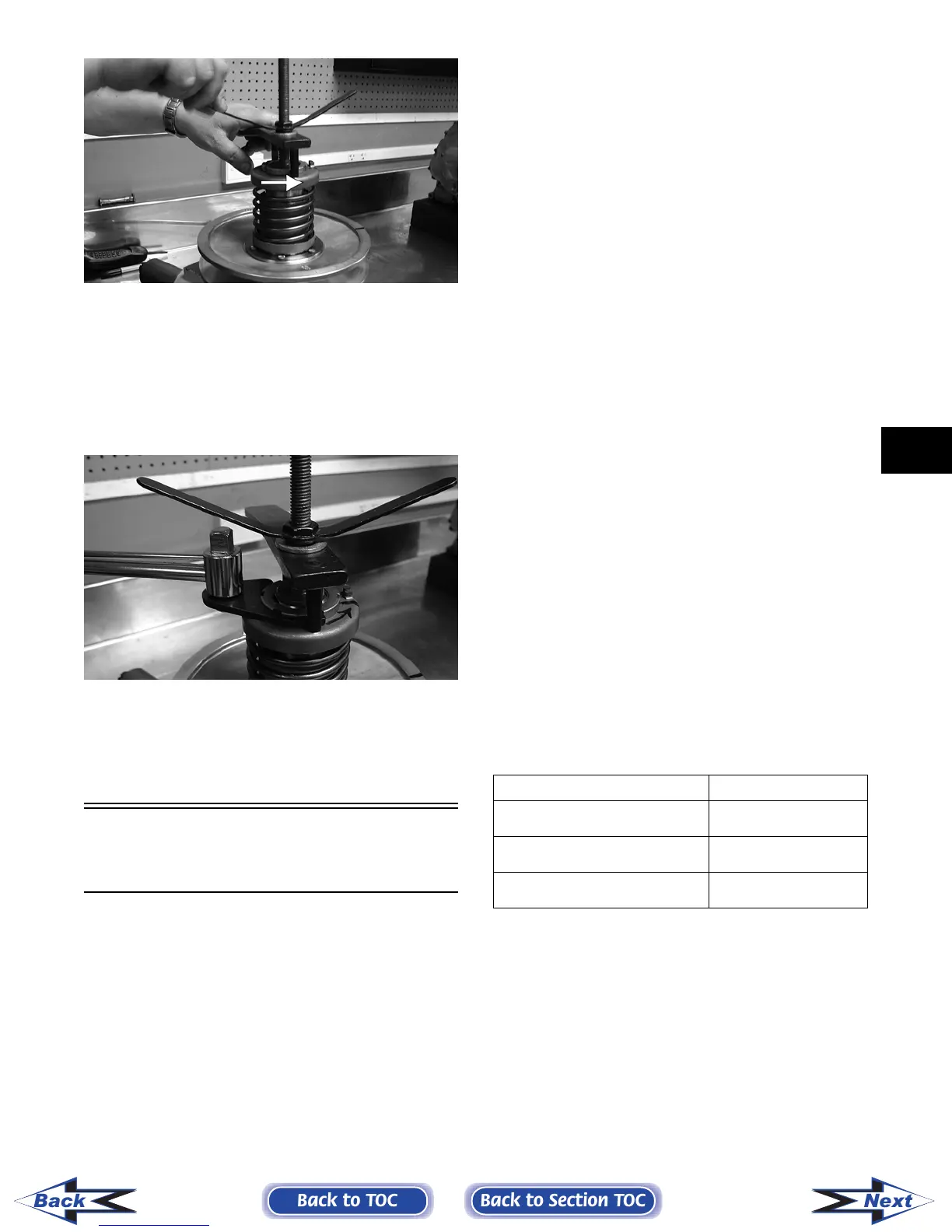

9. Continue compressing the spring while guiding

the spring holder onto the hub. When a slight

resistance is felt, stop turning the wing nut.

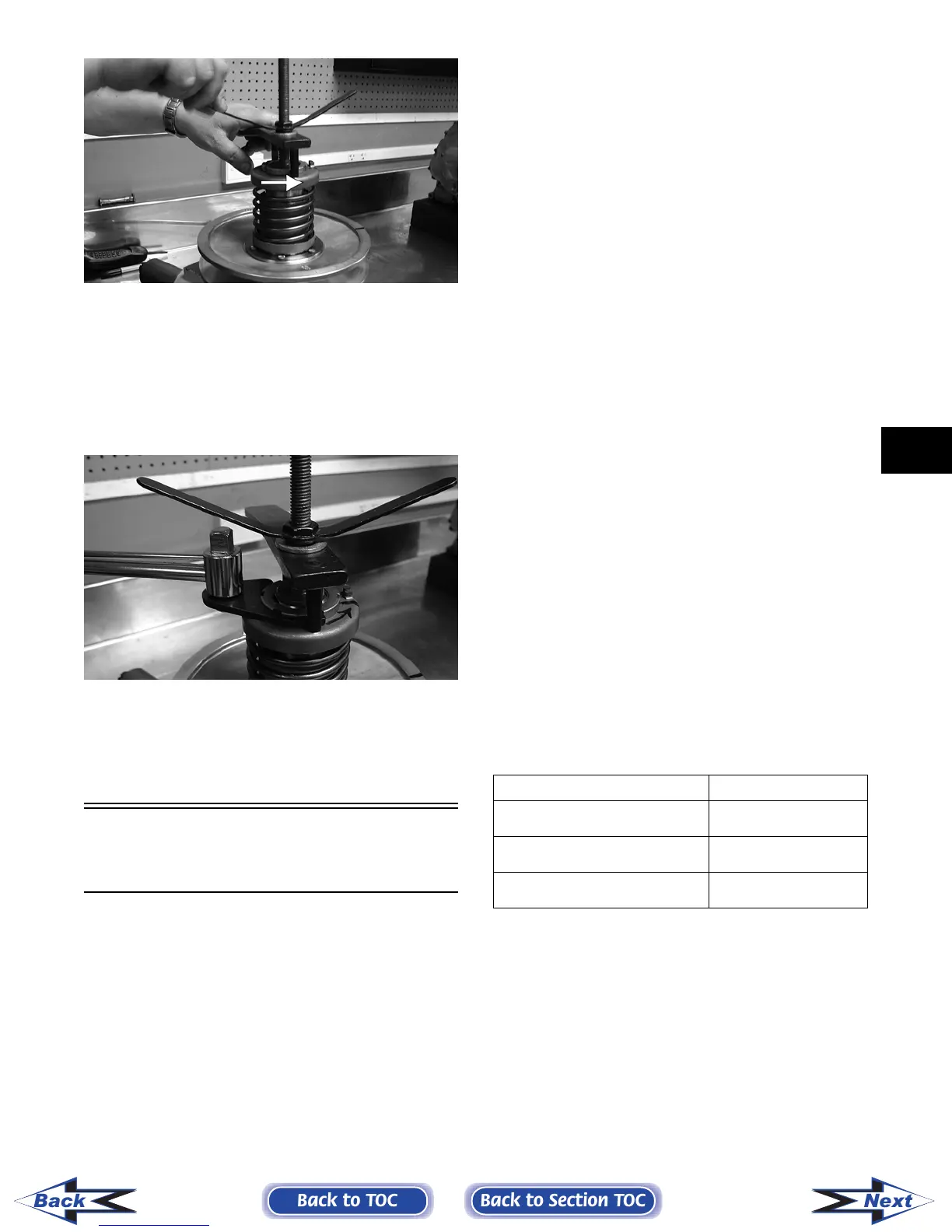

10. Install the nut (threads coated with red Loctite

#271); then tighten the nut to specification using

the spanner and a torque wrench.

CD066

11. Remove the wing nut, washer, and holding han-

dle; then remove the driven pulley from the pul-

ley compressor.

Servicing Center

Crankcase Components

NOTE: Whenever a part is worn excessively,

cracked, damaged in any way, or out of tolerance,

replacement is necessary.

SECONDARY GEARS

NOTE: When checking and correcting secondary

gear backlash and tooth contact, the universal

joint must be secured to the front shaft or false

measurements will occur.

Checking Backlash

NOTE: The rear shaft and bevel gear must be

removed for this procedure. Also, always start with

the original shims on the rear shaft.

1. Place the left-side crankcase cover onto the

left-side crankcase half to prevent runout of the

secondary transmission output shaft.

2. Install the secondary driven output shaft assem-

bly onto the crankcase.

3. Mount the dial indicator so the tip is contacting

a tooth on the secondary driven bevel gear.

4. While rocking the driven bevel gear back and

forth, note the maximum backlash reading on

the gauge.

5. Acceptable backlash range is 0.05-0.33 mm

(0.002-0.013 in.).

Correcting Backlash

NOTE: If backlash measurement is within the

acceptable range, no correction is necessary.

1. If backlash measurement is less than specified,

remove an existing shim, measure it, and install

a new thinner shim.

2. If backlash measurement is more than specified,

remove an existing shim, measure it, and install

a thicker shim.

NOTE: Continue to remove, measure, and install

until backlash measurement is within tolerance.

Note the following chart.

Checking Tooth Contact

NOTE: After correcting backlash of the second-

ary driven bevel gear, it is necessary to check

tooth contact.

1. Remove the secondary driven output shaft

assembly from the left-side crankcase half.

2. Clean the secondary driven bevel gear teeth of

old oil and grease residue.

3. Apply a thin, even coat of a machinist-layout

dye to several teeth of the gear.

Backlash Measurement Shim Correction

Under 0.05 mm (0.002 in.) Decrease Shim

Thickness

At 0.05-0.33 mm

(0.002-0.013 in.)

No Correction Required

Over 0.33 mm (0.013 in.) Increase Shim

Thickness

Back to TOC

Back to Section TOC

Next

Back

FOR ARCTIC CAT ATV DISCOUNT PARTS CALL 606-678-9623 OR 606-561-4983

www.mymowerparts.com

Loading...

Loading...