7. Service Procedures (Undefined variable: MyVariables.ProductName)

Troubleshooting Part Number: PF40-DI-00010 Rev. A

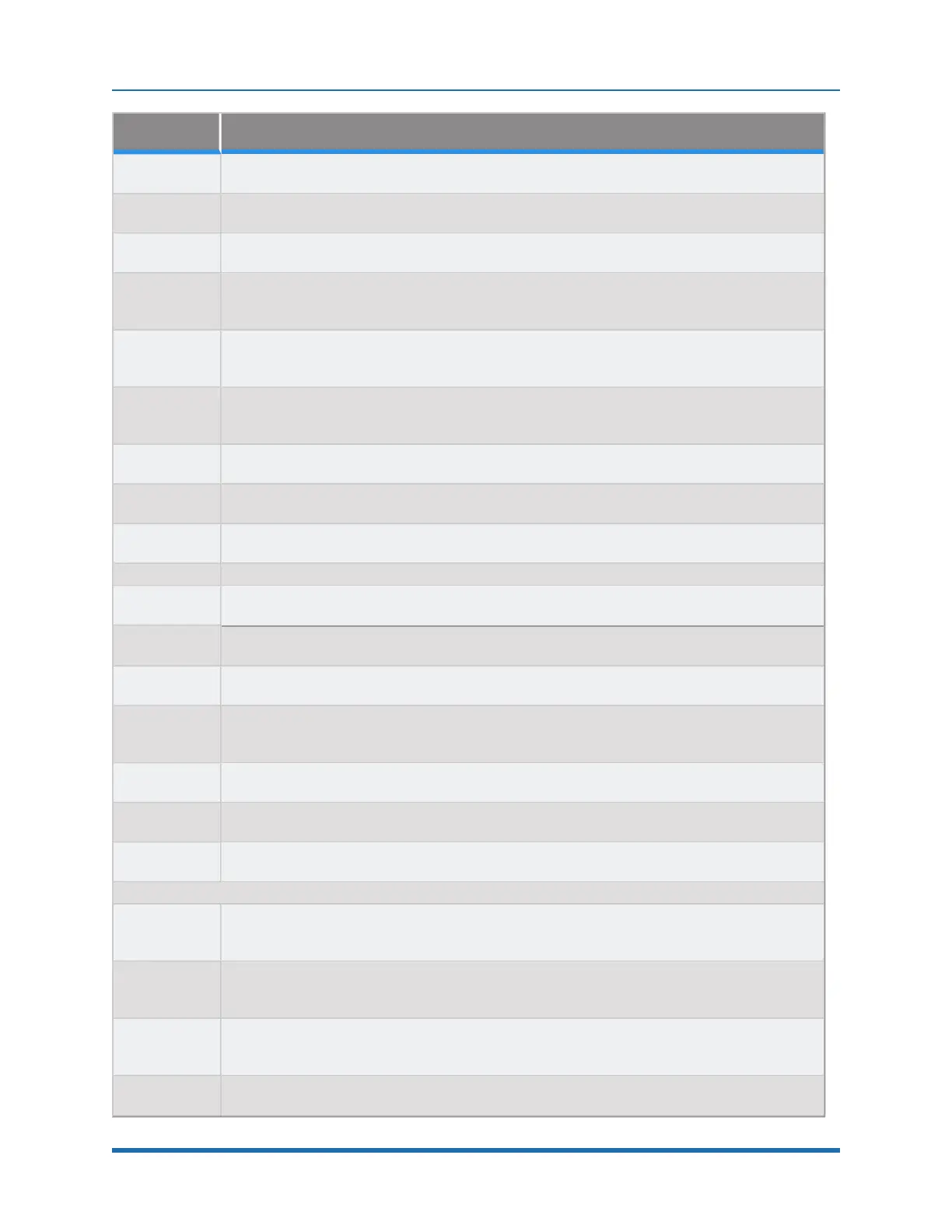

Symptom Recommended Action

“Encoder

Battery Low”

Replace absolute encoder battery in base of robot

“Encoder

Battery Down”

If encoder cable has been disconnected, recalibrate robot. If battery voltage has dropped below

2.5V replace encoder battery and recalibrate robot.

“Encoder

Operation Error”

Joint rotated too quickly with power off. See Procedure below.

“Encoder Data,

Accel/decel

Limit Error”

Check that the FPGA code is dated Jan 25, 2012 or later. Upgrade FPGA if necessary. Encoder

cable may be damaged and encoder is getting intermittent communication, causing apparent

jumps in position. Check encoder connectors on flat ribbon cable. Replace cable. Replace motor.

“Encoder

Communication

Error”

Check that the FPGA code is dated Jan 25, 2012 or later. Check encoder connectors on flat ribbon

cable. Replace encoder cable or motor/encoder.

"Encoder

quadrature

error"

Replace slip ring. Replace motor/encoder (only Gripper motor ).

"Missing zero

index"

See "Encoder quadrature error"

“Motor duty

cycle exceeded”

Reduce speed or acceleration of robot. Check for instability.

“Amplifier under

voltage”

Motor power supply has reached current limit and shutdown. Slow down robot. Check Energy

Dump PCA. Replace 48V supply.

“Amplifier Fault” Check harness and motor for shorts.

“Amplifier Over

Voltage”

Replace energy dump board. Check harness for shorts.

“Soft Envelope

Error”

Make sure robot not pressing against surface. If this occurs on the gripper repeatedly, replace slip

ring.

“Hard Envelope

Error”

Typically means robot has crashed into something.

Pneumatic

Gripper Sensor

not working

Check continuity of cable through wrist. Check green lights on sensor to see if sensor is triggering.

“Time Out

Nulling Error”

Check that joint is free to move with brake off. Check that joint is not vibrating or unstable. If

unstable check belt tension. If Gripper, replace slip ring after checking that brake releases.

“Joint Out of

Range”

The joint actual or commanded position may be beyond the software limit stop. Move joint back

into range while monitoring virtual pendant or check program for commanded position.

“PAC Files

Corrupted”

See recovering from corrupted PAC Files

Physical or audible problem

Brown streaks

on linear

bearing

Clean with alcohol and add grease to bearing blocks. This should not be required sooner than

20,000 hours of run time. Grease is Alvania Grease EP2 from Shell.

Mechanical

noise from any

joint

Check joint bearings for failure. Re-tension belt.

Loud buzzing or

vibration from

any joint

Re-tension timing belts. If timing belt will not hold tension, replace.

Squeaking from

Z belt

Apply thick grease to front and rear edges of belt, (Mobile 222 XP). Belt can get stiff over time and

squeak against pulley flanges.

93

Copyright © 2023, Brooks Automation

Loading...

Loading...