3. Collaborative Robot Safety (Undefined variable: MyVariables.ProductName)

General Information Part Number: PF40-DI-00010 Rev. A

5.10.5 Power and force limiting by inherent design or control

“The power or force limiting function of the robot shall be in compliance with 5.4. If any parameter

limit is exceeded, a protective stop shall be issued.”

Section 5.4 requires the system designer to perform a Performance Level (PL) or Safety Integrity

Level requirement (SIL) check based on the robot AND the application tooling and workcell. For

example, a safe robot may still need safety interlock screening if it is moving a dangerous tool. This

requires the application designer to review the requirements of 10218-2:2011, which addresses

robots in workcells.

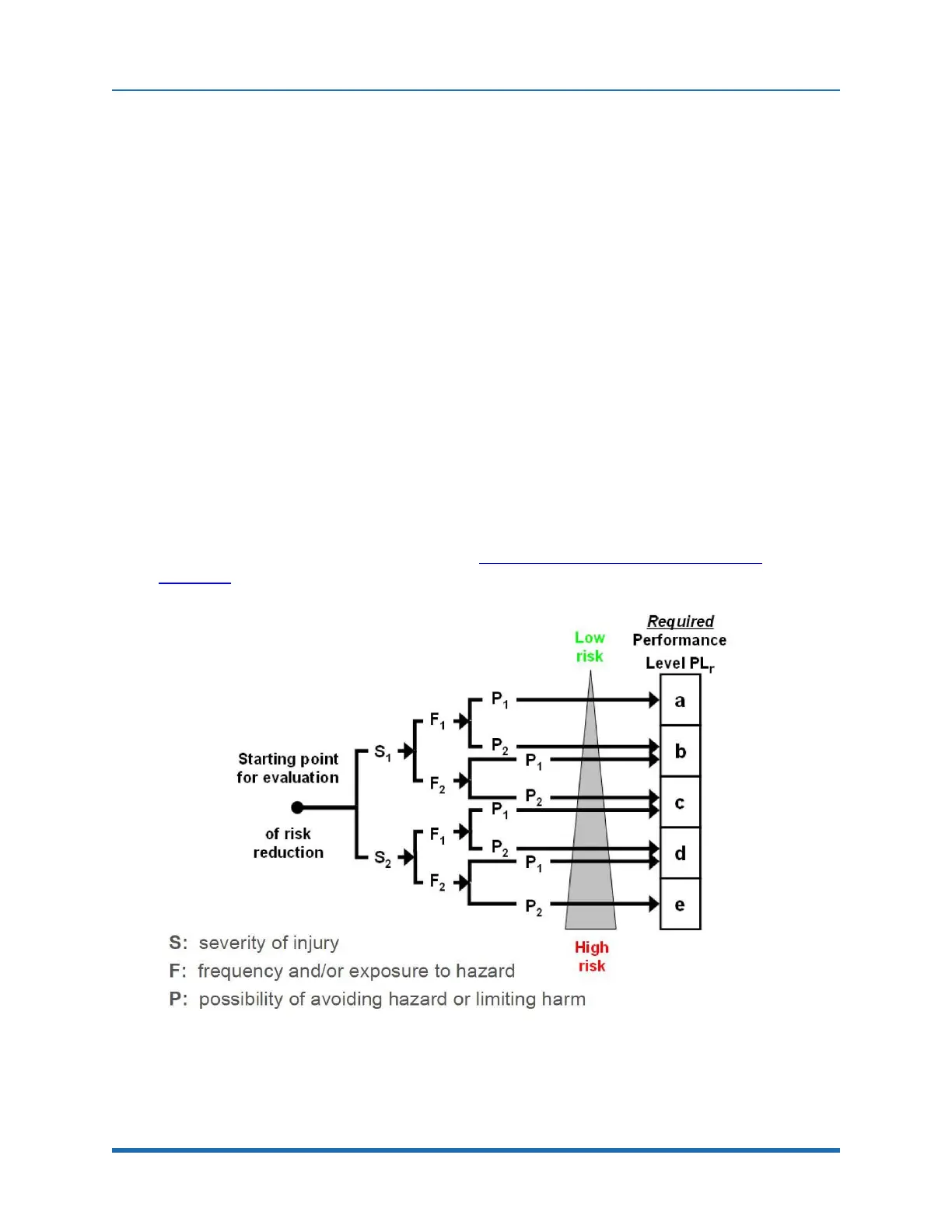

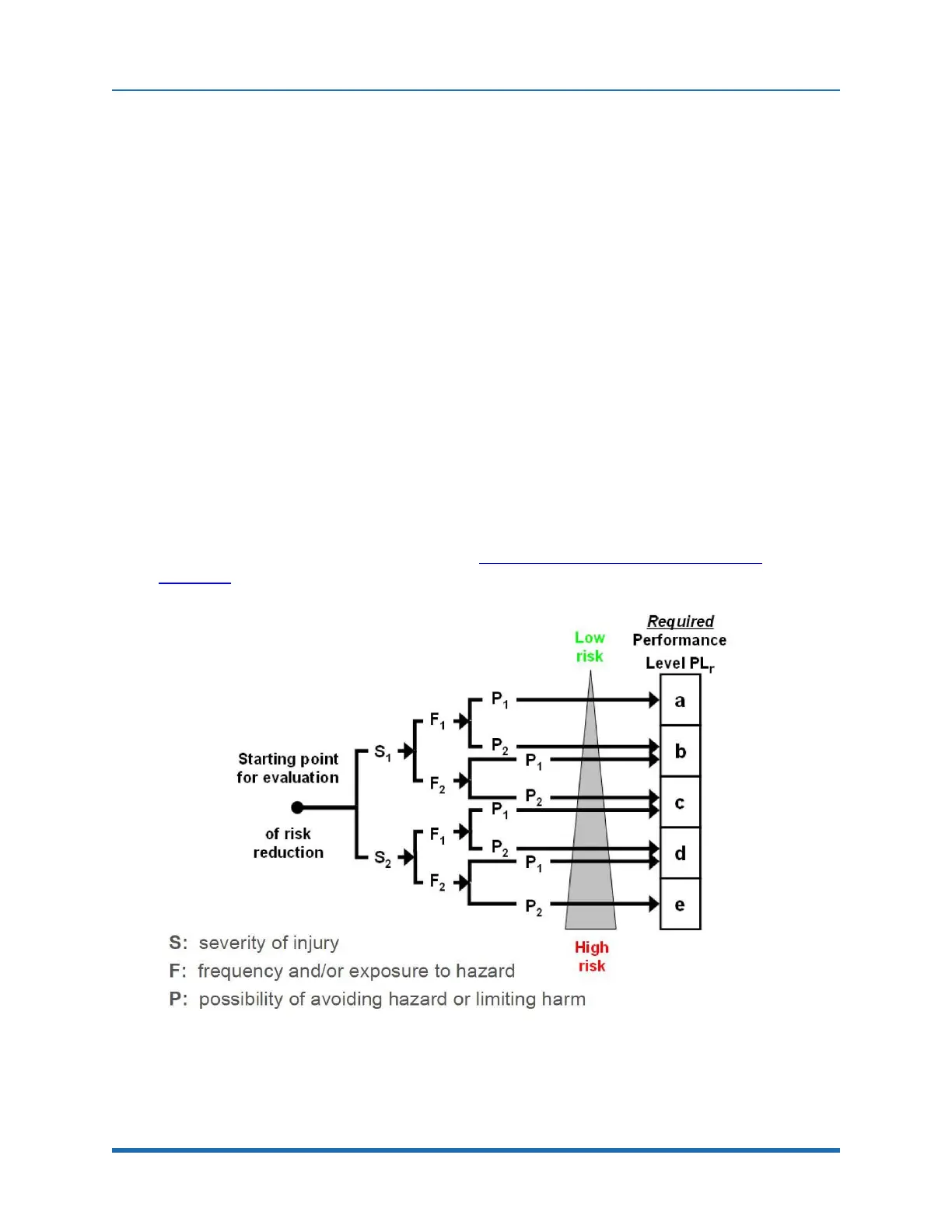

Determining a Machine’s Required Performance Level (PLr).

ISO 13849-1:2006 Annex A provides tables and a worksheet to identify a machine’s Required

Performance Level requirements. Figure 3-1 shows a flow chart for determining Performance

Levels. Briefly these are: Select S1 for slight injuries (normally reversible) and S2 for serious injuries

or death. Select F1 for infrequent exposure to a hazard (for example only from time to time) and F2

for frequent exposure (for example continuously entering workcell). Select P1 for easily recognizing

and avoiding a hazard (for example a repetitive motion) and P2 for a hazard that may be difficult to

avoid (for example a sudden, non-repetitive motion that may trap an operator). An example of

determining PL for a PF400 workcell is given in Appendix F: Example Performance Level

Evaluation, where it is shown that a PL of “a” is sufficient for the workcell.

Figure 3-1: Flow chart for Determining Performance Levels, Risk Estimation by Risk Graph

27

Copyright © 2023, Brooks Automation

Loading...

Loading...