7. Service Procedures (Undefined variable: MyVariables.ProductName)

Tensioning the J3 Belt (Before 2014) Part Number: PF40-DI-00010 Rev. A

Step Action

5.

Remove the Z Carriage Stiffener Plate by removing the M3 X 6 FHCS attaching it to the Z

Carriage (shoulder).

6.

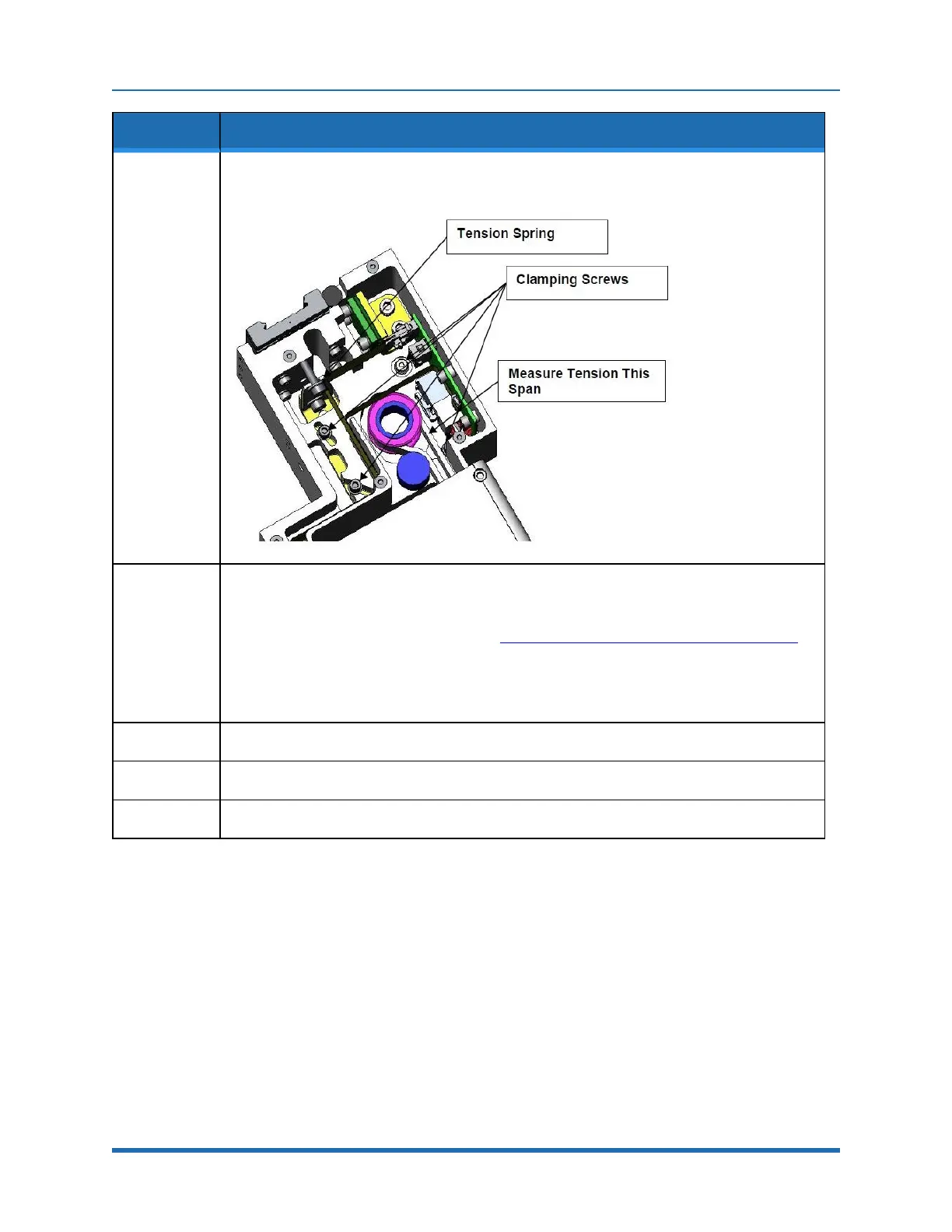

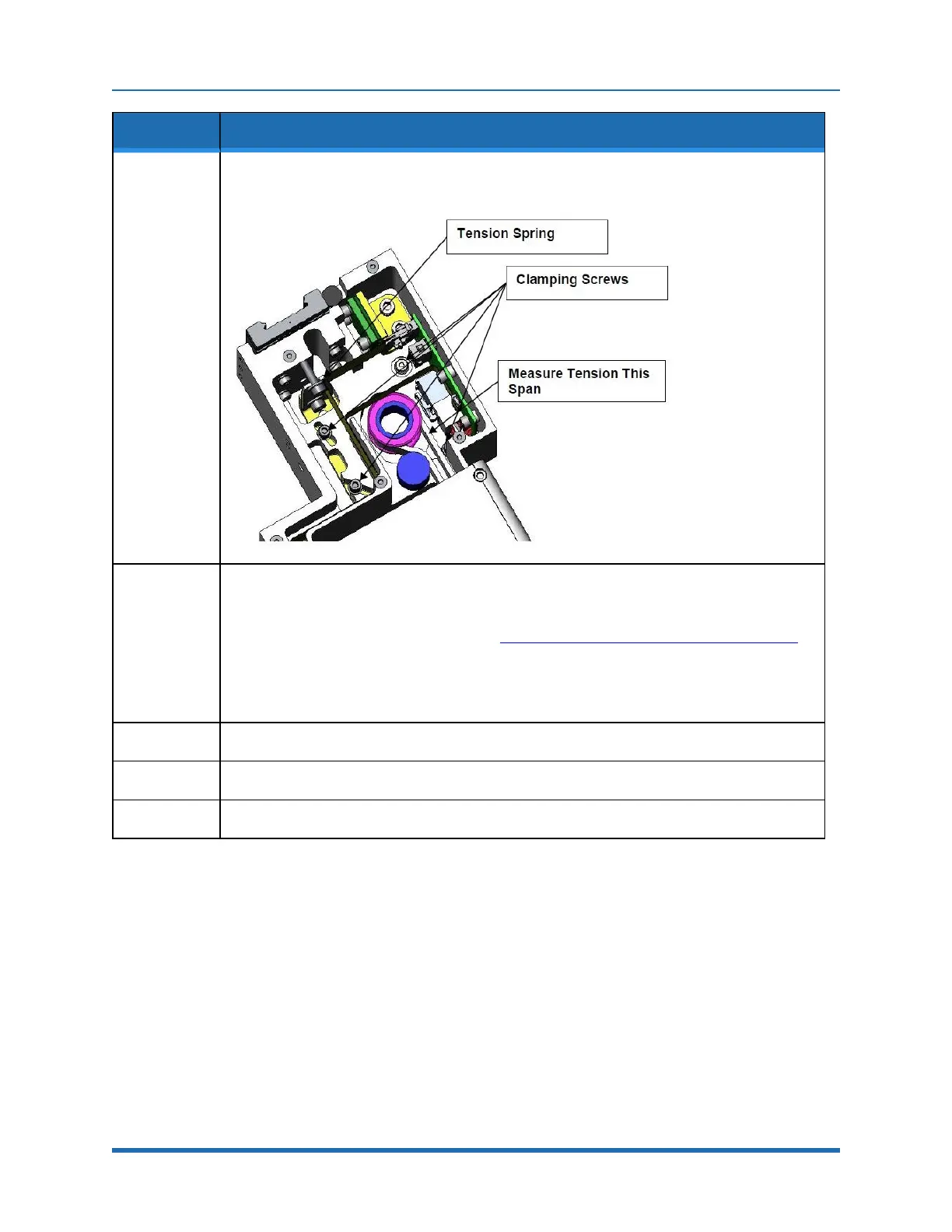

Loosen the (3) M3 SHCS and (1) M4 Shoulder screw clamping the J2 Motor Mount Plate to the

Z Carriage. It may be necessary to remove the tie wrap securing the J2 Motor cables to the Z

carriage in order to access the clamping screw under these cables. It is best to measure the belt

tension with a tension meter as described in Appendix E: Belt Tensions, Gates Tension Meter. If

a belt tension meter is not available, the Tension Leaf Spring will automatically reset the belt

tension. It is helpful to jiggle the motor a little bit to be sure any friction is overcome. The motor

can be easily grasped by reaching under the Z carriage (shoulder). Then re-tighten the clamping

screws. Replace the tie wrap if it was removed.

7.

Replace the Z Carriage Stiffener Plate.

8.

Replace the Front Cover.

9.

Replace the Top Plate.

Tensioning the J3 Belt (Before 2014)

Tools Required:

l

Gates Sonic Belt Tension Meter, Model 507C

l

3.0 mm hex driver or hex L wrench

l

2.5 mm hex driver or hex L wrench

105

Copyright © 2023, Brooks Automation

Loading...

Loading...