2. Introduction to the Hardware (Undefined variable: MyVariables.ProductName)

Machine Safety Part Number: PF40-DI-00010 Rev. A

Soft E-Stop

A "Soft E-Stop" initiates a rapid deceleration of all robots currently in motion and generates an error

condition for all GPL programs that are attached to a robot. This property can be used to quickly halt

all robot motions in a controlled fashion when an error is detected. A soft E-Stop is typically

generated by an application program under conditions determined by the programmer.

This function is similar to a "Hard E-Stop" except that soft E-Stop leaves High Power enabled to the

amplifiers and is therefore used for less severe error conditions. Leaving power enabled is

beneficial in that it prevents the robot axes from sagging and does not require high power to be

manually re-enabled before program execution and robot motions are resumed. This function is

also similar to a Rapid Deceleration feature except that a Rapid Deceleration only affects a single

robot and no program error is generated.

If set, the SoftE-Stop property is automatically cleared by the system if High Power is disabled and

re-enabled.

Hard E-Stop

A Hard E-Stop is generated by one of several hardware E-Stop inputs and causes motor power to

be disabled. However, there is a parameter that determines a delay between the time the hard E-

Stop signal is asserted and the time the motor power supply relay is opened. This delay is nominally

set at 0.5 seconds. It may be adjusted by an operator with administrator privileges. On the web

based operator interface menu, go to Setup/Parameter Database/Controller/Operating Mode/ and

set parameter 267 to the desired delay. If this delay is set to 0, the high-power relay will be disabled

within 1ms.

For the PreciseFlex 400 robot, the shoulder, elbow, and wrist axes do not have mechanical brakes.

Therefore, leaving the motor power enabled for 0.5 sec allows the servos to decelerate the robot.

The servos will typically decelerate the robot at 0.12G, or 1250 mm/sec

2

. If the robot is moving at a

speed of 500 mm/sec, the distance traveled will be 100 mm to reach a full stop, and the time will be

0.4 sec.

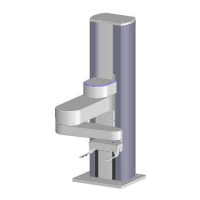

Releasing a Trapped Operator: Brake Release Switch

Should a hard E-Stop be triggered, the Z brake will engage, and motor power will be disconnected

from all motors. As the J2, J3, and J4 axes have no brakes, they may be freely pushed by the

operator. To release the Z brake, the operator may press the brake release switch, under the inner

link, as long as 24 VDC is present. It is not necessary for motor power to be on for the brake release

to work.

25

Copyright © 2023, Brooks Automation

Loading...

Loading...