7. Service Procedures (Undefined variable: MyVariables.ProductName)

Tensioning the J2 Belt Part Number: PF40-DI-00010 Rev. A

Step Action

3.

Remove the Front Cover by lifting it out vertically.

4.

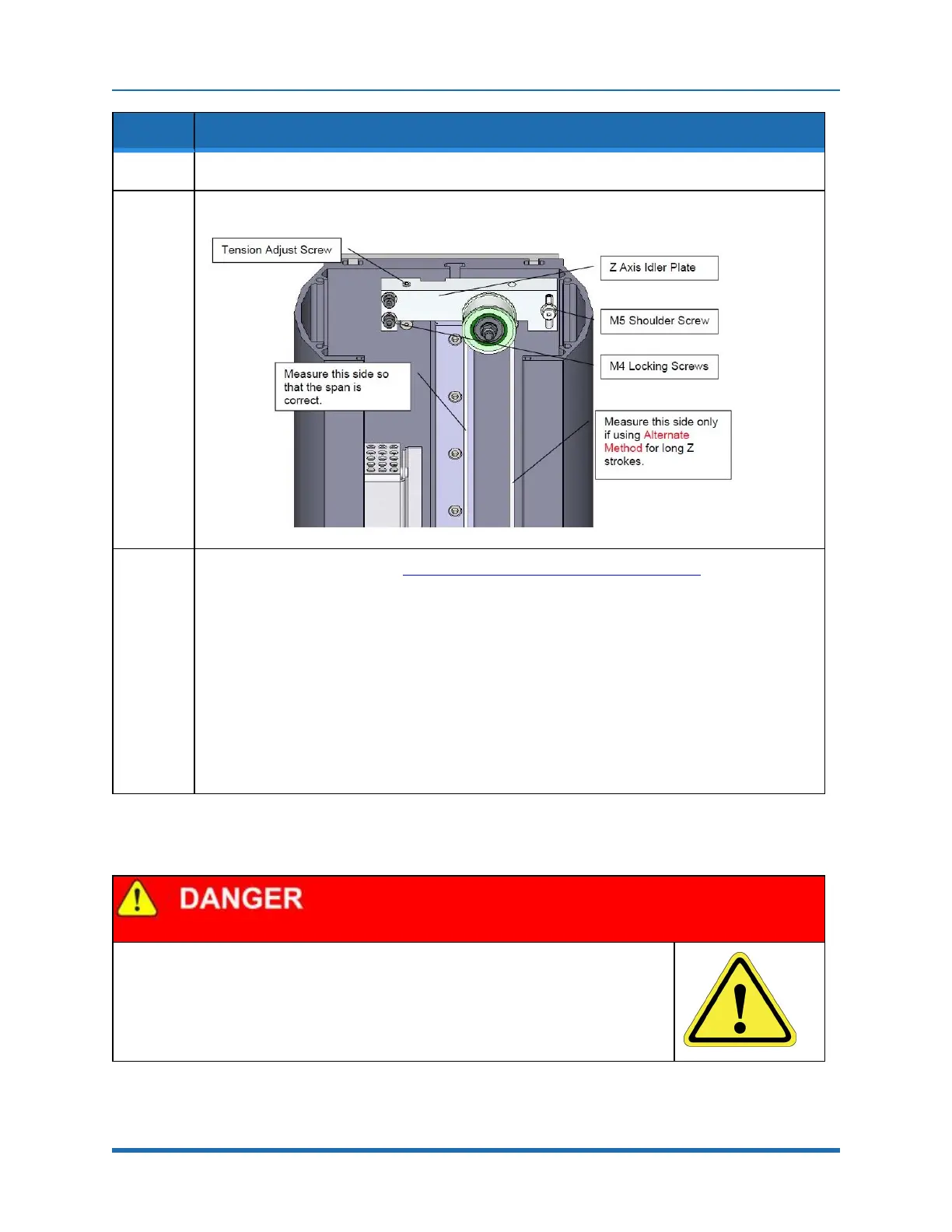

Loosen the (2) M4 locking screws and the M5 shoulder screw on the Z idler plate.

5.

The tension is set to the value in Appendix E: Belt Tensions, Gates Tension Meter by adjusting the

M5 set screw which pushes on a spring in the Z Axis Idler Plate. Re-tighten the 3 screws and

replace the Front Cover and Top Plate.

Alternate Method:

For the 750 mm and 1160 mm Z travel robots, it can sometimes be difficult to get a good tension

reading for the spans for these long belts, which are 880 mm and 1290 mm respectively and as a

result have low vibration frequencies. In this case it may be easier to position the Z carriage so that

the span from the top idler pulley to the Z carriage is 530 mm, which is the span for the 400 mm Z

stroke when measured on the left hand side of the belt as shown above. With the carriage at this

location with a span of 530 mm, for these longer travel Z strokes, a user can then measure the

tension on the right hand side of the belt, and use the values for tension and frequency for the 400

mm Z stroke.

Tensioning the J2 Belt

Electrical Shock

Before tensioning the timing belts, the AC power should be disconnected. Removing the

front cover allows access to the AC power terminals.

103

Copyright © 2023, Brooks Automation

Loading...

Loading...