3. Collaborative Robot Safety (Undefined variable: MyVariables.ProductName)

General Information Part Number: PF40-DI-00010 Rev. A

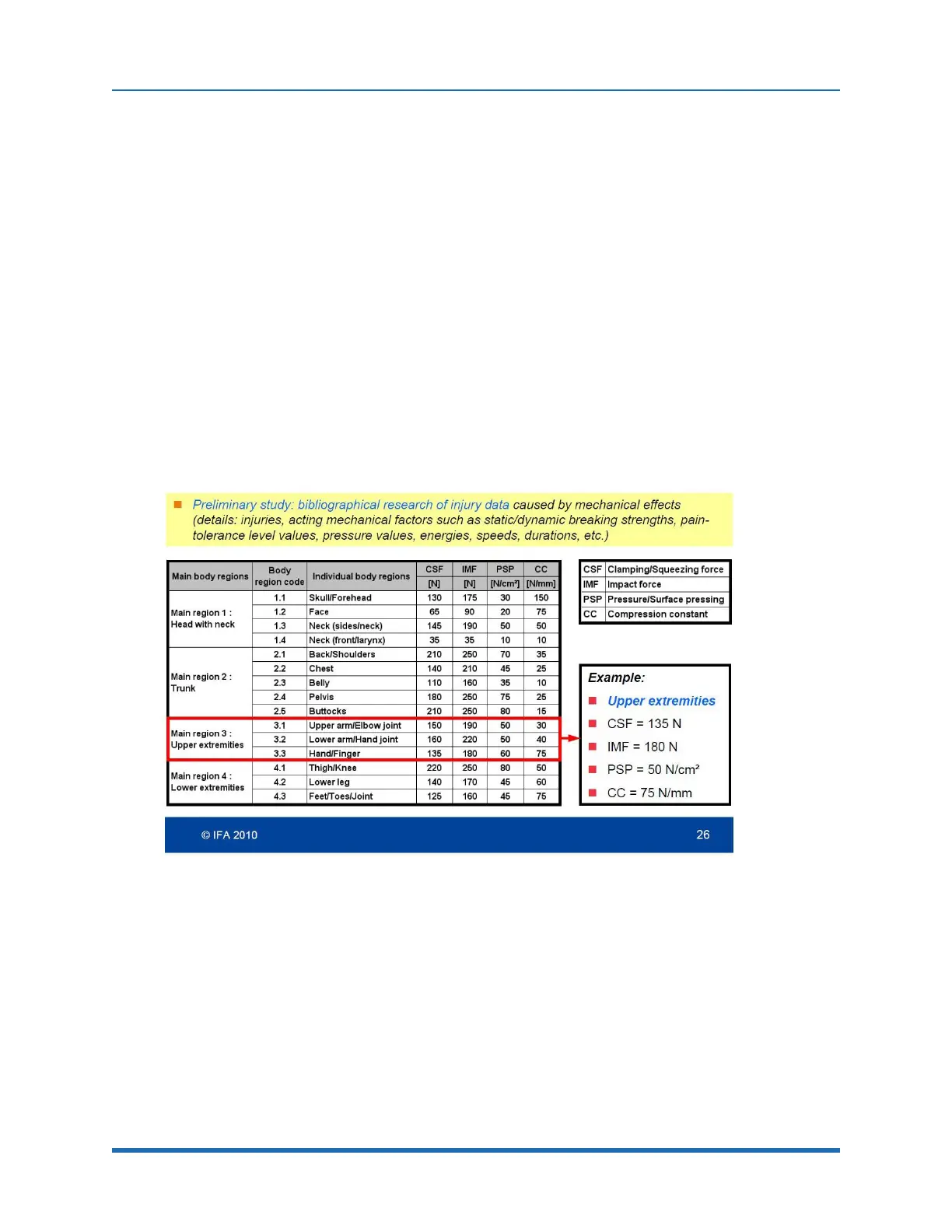

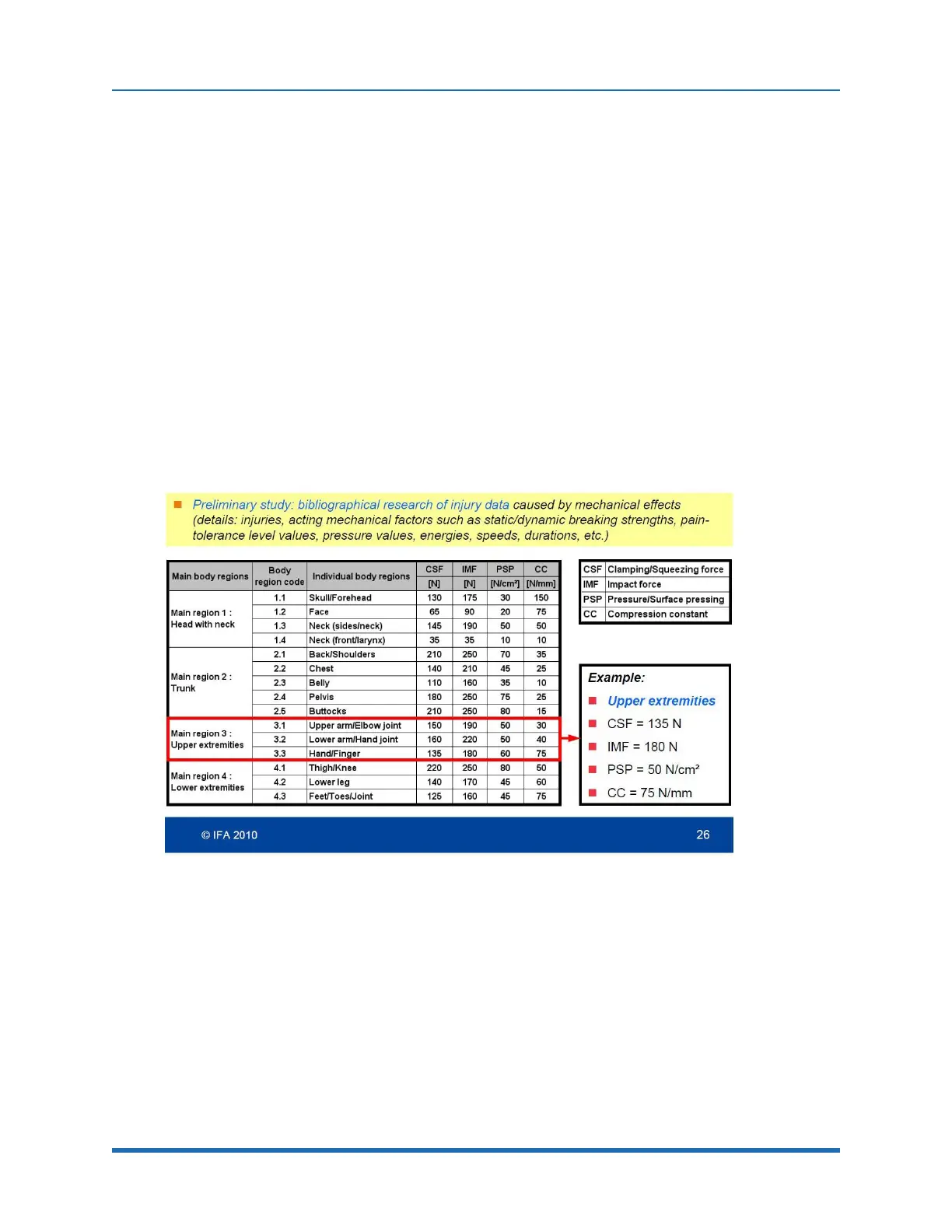

standard. Note in particular the column for CC, or compression constant, for various parts of the

body. This data is useful in determining the stiffness or compliance for force sensors when taking

collision data. If a rigid robot part is driven into a rigid sensor the forces will be unrealistically high

when compared to bumping into a more compliant human.

A useful number that may be extracted from this data for testing is a compression constant of 75

N/mm, which is consistent with the hand and the face. For collisions, a higher compression constant

will generate higher collision forces. It is interesting to note that while front of the neck has a fairly

low impact force pain threshold of 35 N, the neck must be compressed 3.5 mm to reach this force,

while in the case of the hand, which has an impact force pain threshold of 180 N, the compression

distance is less, at 2.4 mm even though the force is much higher.

In considering the design and testing of a robot that meets these “Collaborative” standards, the

likelihood of an impact to a particular area should be considered. The hand is most likely to be

pinched in any pinch points, whereas the skull is less likely to be pinched as most operators that

may be extending their hands into the workspace will be quite wary of getting their heads between a

moving robot and a hard surface.

Figure 3-2: Limit Values (Literature Survey/Exemplary Control Tests)

Types of Forces

There are four types of forces that should be considered and tested when designing a

“Collaborative” robot workcell. These are:

1. Clamping/squeezing force. This is the quasi-static case of the robot pressing a compliant part

of the human body against a surface. This force should be considered when the robot is under

manual control and for low speed collisions.

29

Copyright © 2023, Brooks Automation

Loading...

Loading...