Brooks Automation Appendices

Part Number: PF40-DI-00010 Rev. A Appendix D: Preventative Maintenance

Appendix D: Preventative Maintenance

For help with preventative maintenance, addressing error codes, or any other issue, contact

support_preciseflex@brooksautomation.com.

Every one to two years, the following preventative maintenance procedures should be performed.

For robots that are continuously moving 24 hours per day, 7 days a week at moderate to high

speeds, a one-year schedule is recommended. For robots with low duty cycles and low to moderate

speeds, these procedures should be performed at least once every two years.

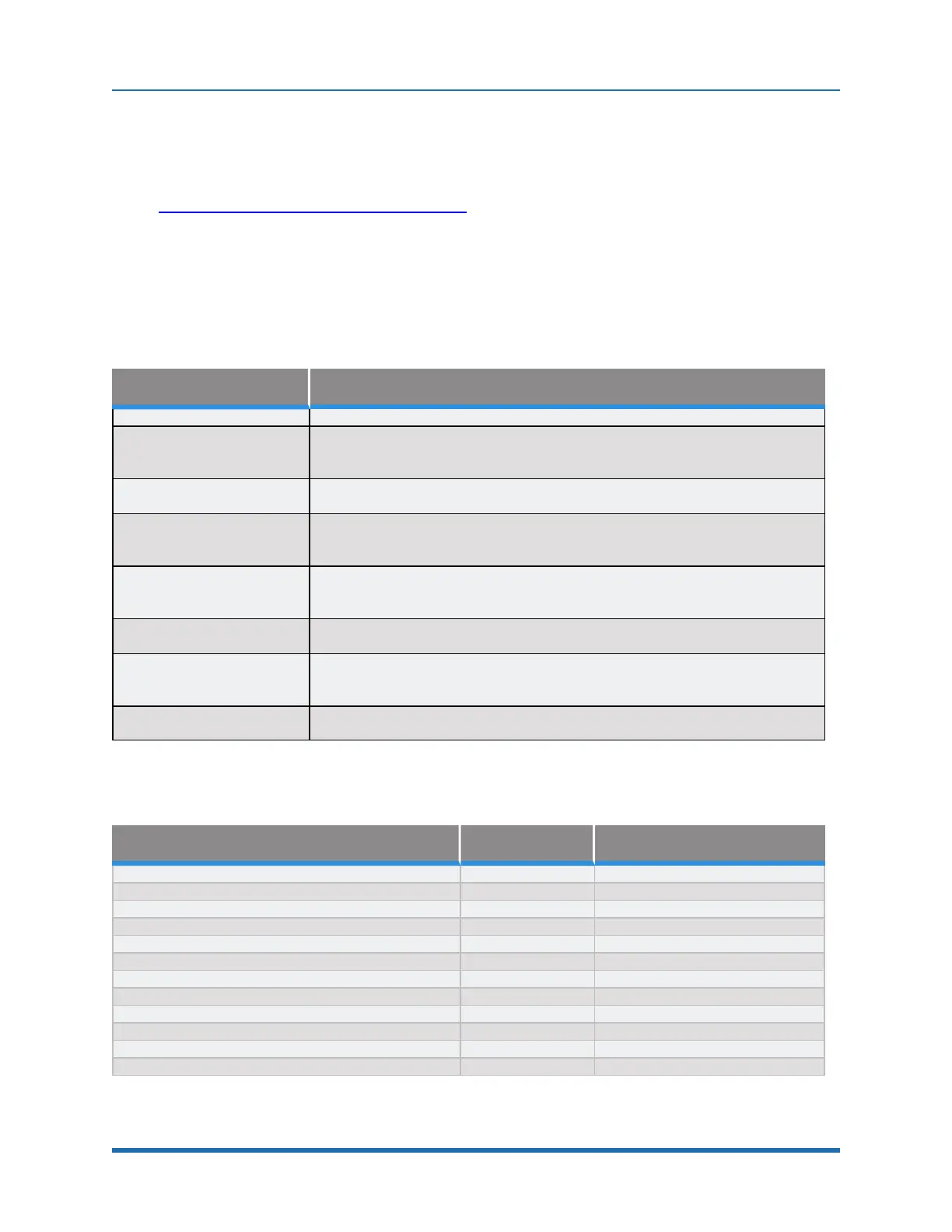

Check List Procedure If Problem Detected

Check all belt tensions Re-tension if necessary

Check air harness tubing in

elbow if present, and theta

axis for any wear

Replace if necessary

Replace timing belt in

optional linear axis

Typically every 6,000 hours of continuous operation

Check all joints in “free

mode” for low bearing friction

and any sticking.

If a bearing is getting stiff, return to factory for bearing replacement.

Check second stage (long) Z

belt for any squeaking

If noisy, add thick grease to front and rear edge of belt if necessary. (Shell 222 XP

or similar). Z timing belt can get stiffer over time (2-3 years) and occasionally start

squeaking against pulley flanges.

Check if front cover is rattling If so, check .125in ID by .062in thick O rings on dowel pins in base plate under

front cover for any deterioration and replace if necessary.

Check Cam Followers on J2

timing belt for grease leaking

or discoloration.

Replace if necessary. Note that earlier units had a 9 mm wide timing belt and later

units (2014, 2015) have a 12 mm wide timing and the Cam Followers are

different. See Appendix C: Spare Parts List.

Replace slip ring For units with electric gripper shipped before April 2015, replace the slip ring.

For units shipped after April 2015, replace the slip ring every third inspection test.

Table 8-4: Preventative Maintenance, Checklist & Procedures

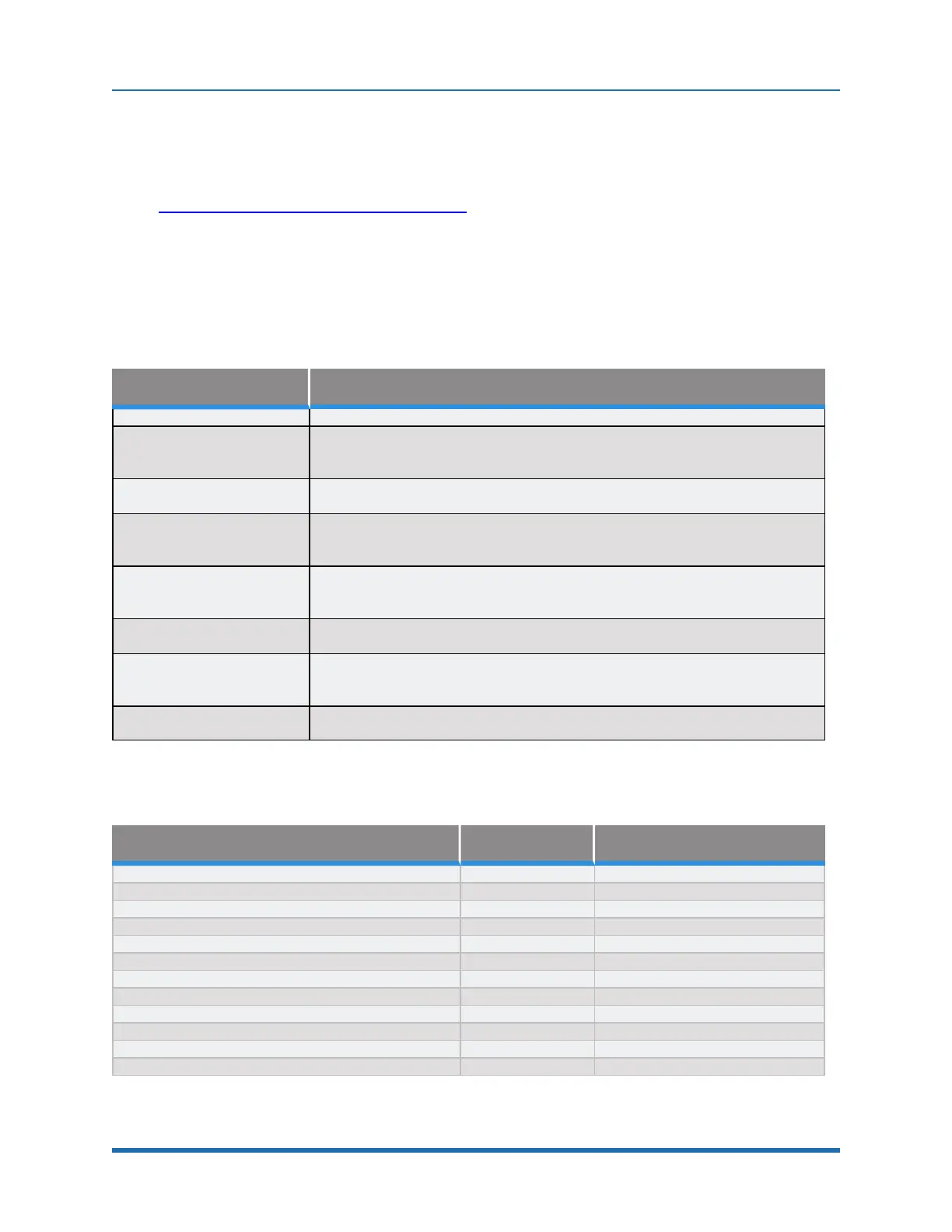

Component Expected Life Action

Revision A, Serial Numbers F0X...

Slip ring 1-3 years Replace component

Ethernet cable (flat black Startech) 2-4 years Replace component

J2 timing belt (9 mm) 2 years Replace component

Motors with pulleys (bonded) 2-10 years Replace assembly if bond broken

Harness (any FFC cables) 4-10 years Replace robot*

Revision B, Serial Numbers F0B...

Slip ring 3-5 years Replace component

Ethernet cable (flat black Startech) 2-4 years Replace component

Revision C, Serial Numbers F0C...

Table 8-5: PF400 PM Schedule by Revision Level & Date

Copyright © 2023, Brooks Automation

162

Loading...

Loading...