Brooks Automation 2. Introduction to the Hardware

Part Number: PF40-DI-00010 Rev. A Machine Safety

Voltage and Power Considerations

The Guidance 1400B controller requires two DC power supplies, a 24 VDC power supply for the

processor and user IO and a separate 48 VDC motor power supply.

Electrical Shock

The Guidance 1400, the 48 VDC, and the 24 VDC power supplies are all open frame

electrical devices that contain unshielded high voltage pins, components and surfaces.

These products are intended to be mounted in a cabinet or machine chassis that is not

accessible when AC line power is turned on.

The PreciseFlex 400 power supplies have an input range of 100 to 240 VAC, +/- 10%, 50/60 Hz.

Inrush current can be as high as 100 Amps at 240 VAC for short periods of time. The power supplies

are protected against voltage surge to 2000 Volts. Transient over voltage (< 50 µs) may not exceed

2000 V phase to ground, as per EN61800-31996. Revisions A and B of the robot are protected

against over current by two 4.0 Amp, 250 V slow blow fuses, for example Littlefuse 0215004.MXP.

The robot consumes less than 200 Watts during normal operation.

The PreciseFlex controller can monitor motor power through its datalogging function. Intermittent

power dropouts can be detected by setting a trigger in the data logger which can record and time-

stamp power fluctuations.

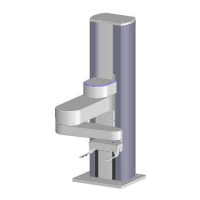

Mechanical and Software Limit Stops

The Z column, shoulder, and elbow have hard limit stops at the end of travel which are factory

installed. The soft-limit stops must be set within the range of these hard stops. The wrist axis has a

slip ring when the electric gripper is installed, allowing unlimited rotation. However, software stops

limit rotation to plus or minus 970 degrees. Since the robot has absolute encoders with battery

backup, even if the robot is turned off, the encoders keep track of joint position. If the wrist axis is

rotated manually beyond the 970 degree software limit stops, it will be necessary to rotate it back to

within the allowed software limits before the robot will run. The joint position can be viewed either on

the optional Manual Control Pendant, or in the Virtual Manual Control Pendant in the Web Based

Operator Interface. (See Guidance Controller Setup and Operation Quick Start Guide) For

pneumatic configurations a sliding hard stop limits the wrist rotation to 540 degrees.

Stopping Time and Distance

The robot control system responds to two types of E-Stops.

Copyright © 2023, Brooks Automation

24

Loading...

Loading...