2007 Buell P3: Chassis 2-7

HOME

WHEELS 2.4

GENERAL

Good handling and maximum tire mileage are directly related

to the care of wheels and tires. Regularly inspect wheels and

tires for damage and wear. If handling problems occur, refer

to Table 2-7.

Keep tires inflated to the recommended air pressure. Always

balance the wheel after replacing a tire.

11WARNING1WARNING

Do not inflate tire beyond maximum pressure as speci-

fied on sidewall. Over inflated tires can blow out, which

could result in death or serious injury. (00027a)

TROUBLESHOOTING

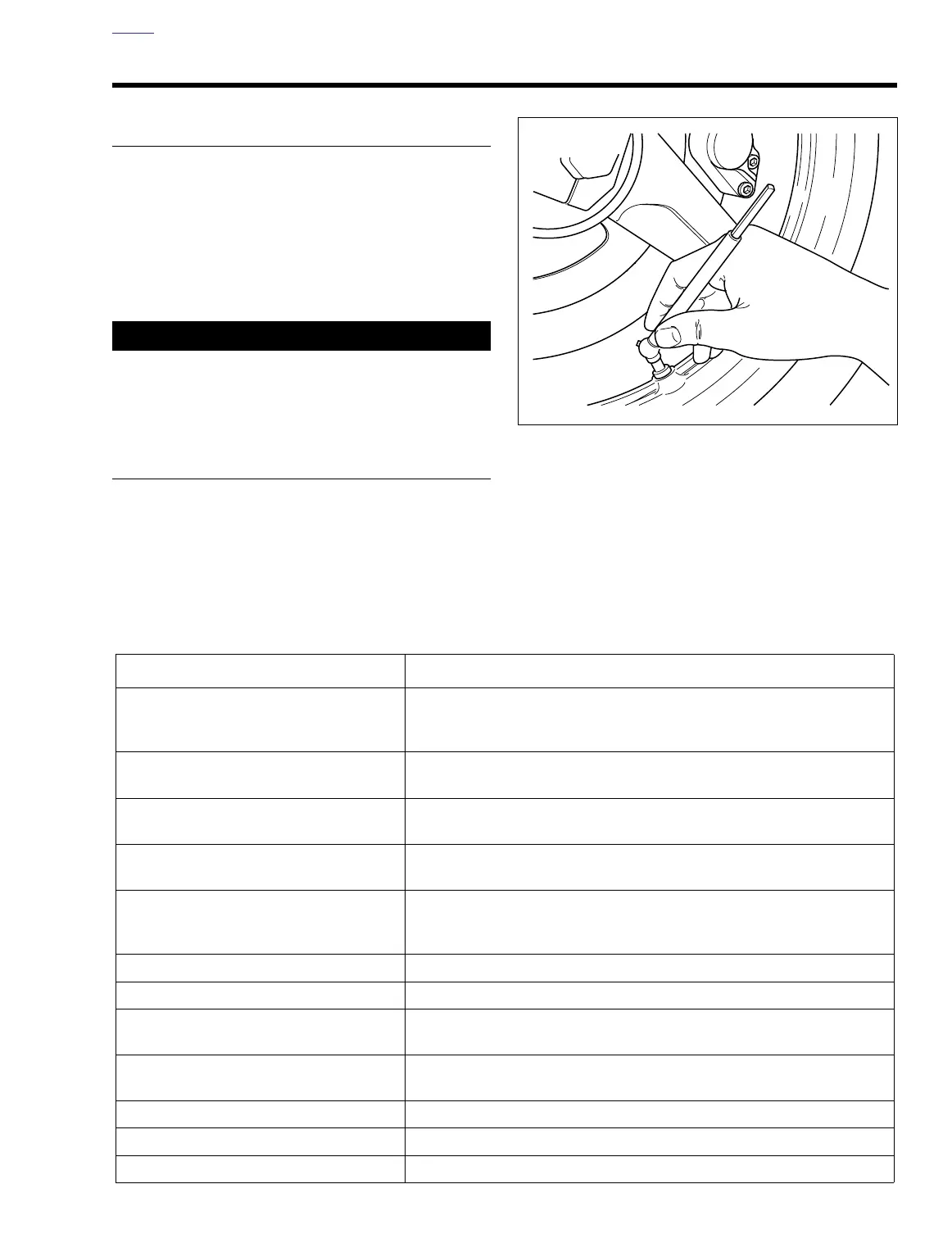

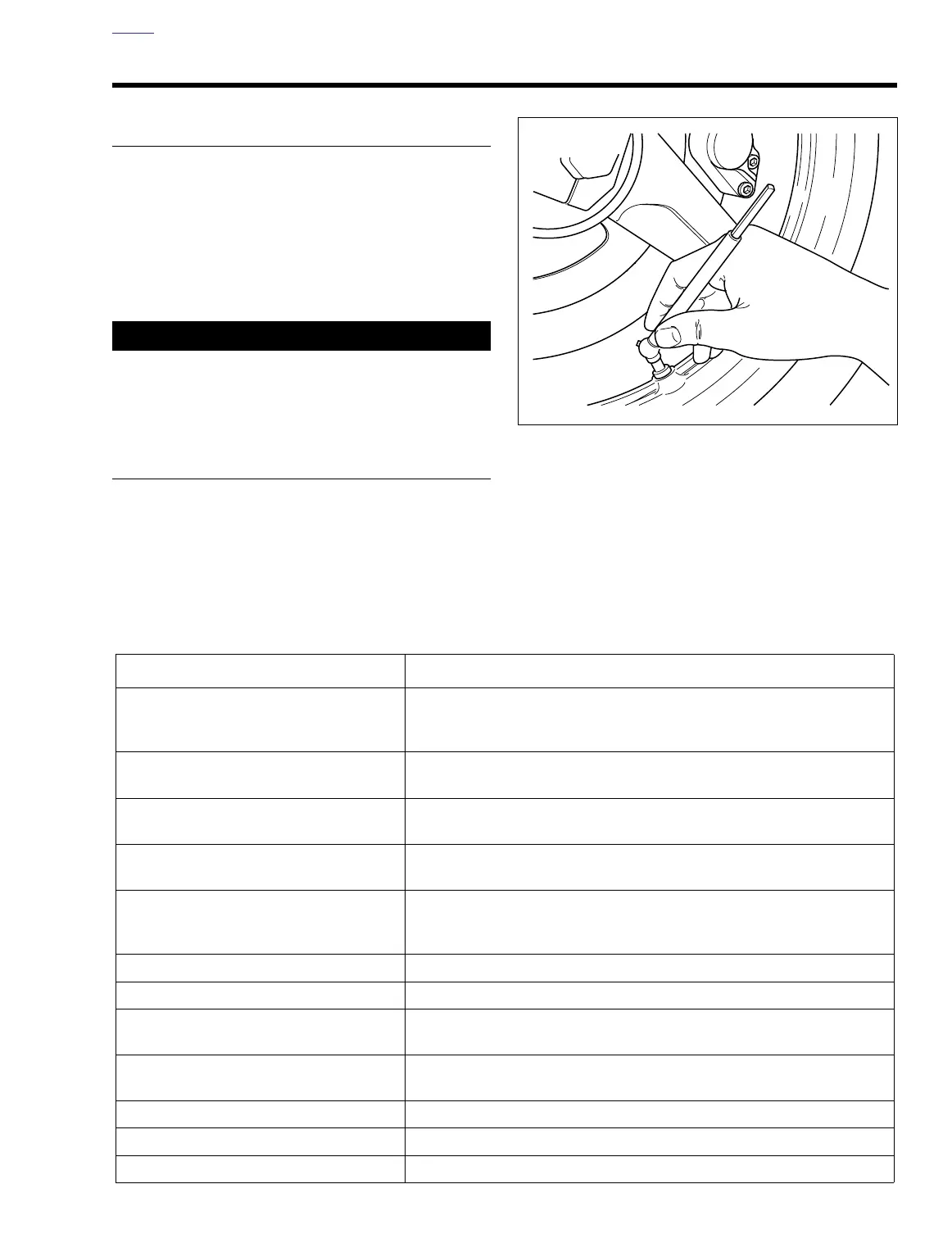

See Figure 2-2. Check tire inflation pressure at least once

each week. At the same time, inspect tire tread for punctures,

cuts, breaks and other damage. Repeat the inspection before

long trips.

Figure 2-2. Checking Tire Inflation Pressure

Table 2-7. Wheel Service

CHECK FOR REMEDY

Loose axle nuts. Apply Loctite 243 (Blue) and tighten front axle nut (metric) to 38-42 ft-lbs

(52-57 Nm).

Tighten rear axle nut (metric) to 49-51 ft-lbs (67-69 Nm).

Excessive side-play or radial (up-and-down)

play in wheel hubs.

Replace wheel hub bearings.

Alignment of rear wheel in frame or with

front wheel.

Repair swingarm as described under 2.19 SWINGARM.

Rims and tires out-of-true sideways; should

not be more than 0.080 in. (2.03 mm).

Replace rims. See 2.9 TIRES.

Rims and tires out-of-round or eccentric

with hub; should not be more than 0.090 in.

(2.29 mm).

Replace rims. See 2.9 TIRES.

Irregular or peaked front tire wear. Replace as described under 2.5 FRONT WHEEL or 2.9 TIRES.

Correct tire inflation. Inflate tires to correct pressure. See 2.2 TIRE SPECIFICATIONS.

Correct tire and wheel balance. Static balance may be satisfactory if dynamic balancing facilities are not

available. However, dynamic balancing is strongly recommended.

Steering head bearings. Correct adjustment and replace pitted or worn bearings. See 2.18 FORK

STEM AND BRACKET ASSEMBLY.

Damper tubes. Check for leaks. See 2.17 FRONT FORK.

Shock absorber. Check damping action and mounts. See 2.15 REAR SHOCK ABSORBER.

Swingarm bearings. Check for looseness. See 2.19 SWINGARM.

Loading...

Loading...