2007 Buell P3: Fuel System 4-23

HOME

THROTTLE POSITION SENSOR 4.6

REMOVAL

NOTE

For electrical diagnostics and troubleshooting, please refer to

7.4 THROTTLE POSITION SENSOR (TP SENSOR).

1. Remove seat.

11WARNING1WARNING

To prevent accidental vehicle start-up, which could

cause death or serious injury, disconnect negative (-)

battery cable before proceeding. (00048a)

2. Unthread bolt and remove battery negative cable (black)

from battery negative (-) terminal.

3. Remove air cleaner assembly. See 1.17 AIR CLEANER.

4. Remove carburetor assembly. See 4.4 CARBURETOR.

5. Locate 6-place Deutsch connector in front of ignition coil

and depress external latch to separate pin and socket

halves. Remove pin terminals from chambers 3 through

5.

NOTE

For instructions on properly removing wire terminals, see

SECTION 7, ELECTRICAL, DEUTSCH ELECTRICAL CON-

NECTORS.

6. Using special TORX bit (Snap-on® TTXR20E), remove

two tamper-resistant T20 TORX screws to release throt-

tle position sensor from carburetor. Pull sensor from car-

buretor bore.

INSTALLATION

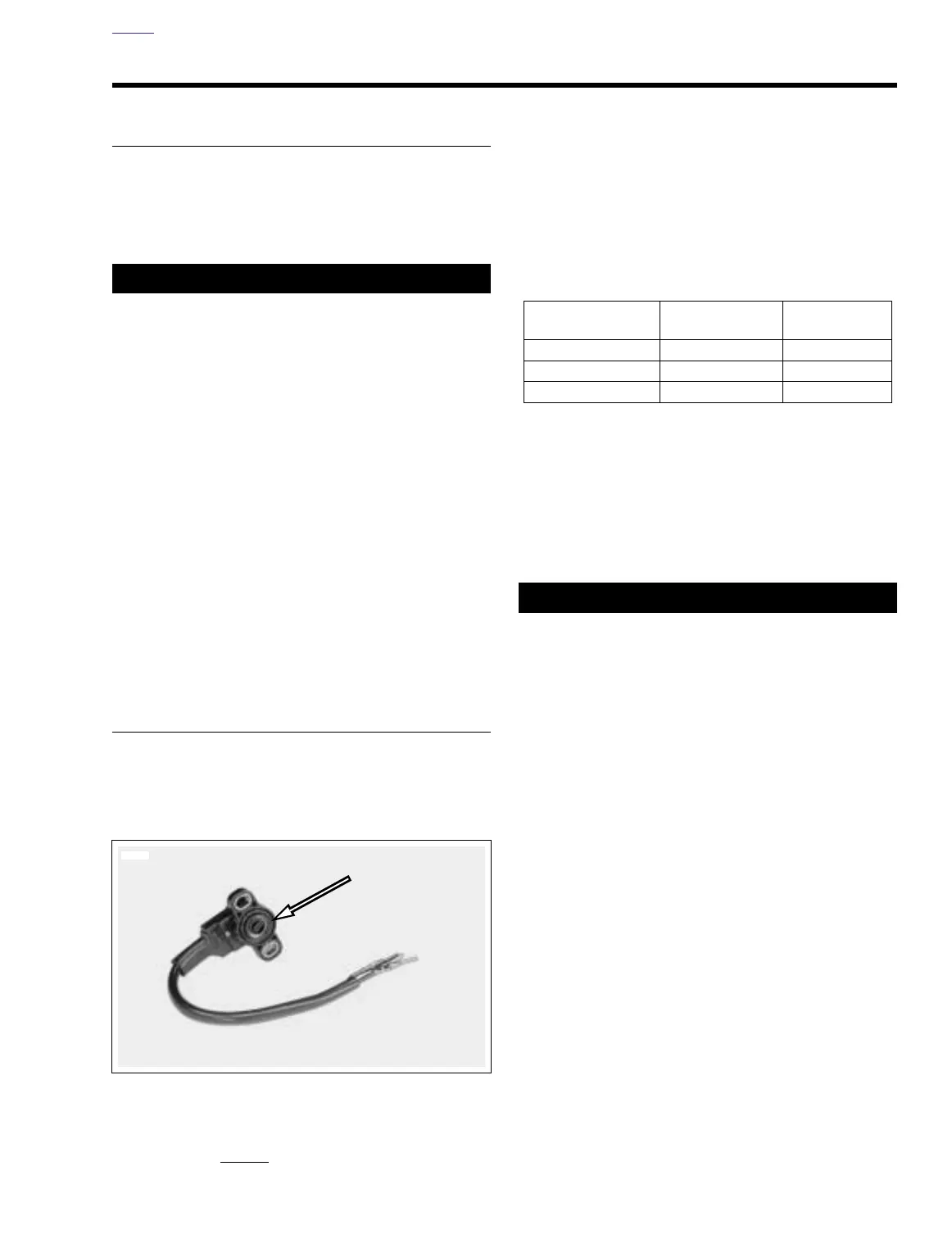

1. See Figure 4-21. Obtain new throttle position sensor. If

old sensor is used, inspect o-ring for cuts, tears or signs

of deterioration. Replace o-ring if necessary.

2. Align holes in throttle position sensor with those in carbu-

retor housing. Using special TORX bit (Snap-on®

TTXR20E), loosel

y install two tamper-resistant T20

TORX screws.

NOTE

The tamper-resistant screws are not to be tightened until the

throttle position sensor has been properly adjusted. See the

instructions under step 6 for details.

3. Locate 6-place Deutsch connector [88] and install pin

terminals. Mate pin and socket halves of connector.

Refer to Table 4-7.

4. Insert bolt through battery negative cable (black) into

threaded hole of battery negative (-) terminal. Tighten

bolt to 72-96 in-lbs (8-11 Nm).

5. Install carburetor assembly. See 4.4 CARBURETOR.

6. Adjust throttle position sensor. See 7.4 THROTTLE

POSITION SENSOR (TP SENSOR).

7. Install air cleaner assembly. See 1.17 AIR CLEANER.

11WARNING1WARNING

After installing seat, pull upward on front of seat to be

sure it is in locked position. While riding, a loose seat can

shift causing loss of control, which could result in death

or serious injury. (00070a)

8. Install seat.

NOTE

Be sure the engine is warmed up to normal operating temper-

ature BEFORE adjusting engine idle speed.

9. Adjust engine idle speed, as follows: With the engine at

normal operating temperature (auto-enrichener valve

closed), adjust the throttle stop screw so the engine idles

at 1200 RPM.

NOTE

To measure engine RPM, use a hand held inductive tachom-

eter to pick up the signal off the spark plug cable.

Figure 4-21. Throttle Position Sensor with O-ring

7753

Table 4-7. Connector [88A]

CHAMBER

NUMBER

WIRE COLOR FUNCTION

3 Light blue Output

4 Yellow Input

5 Black Ground

Loading...

Loading...