7-12 2007 Buell P3: Electrical

HOME

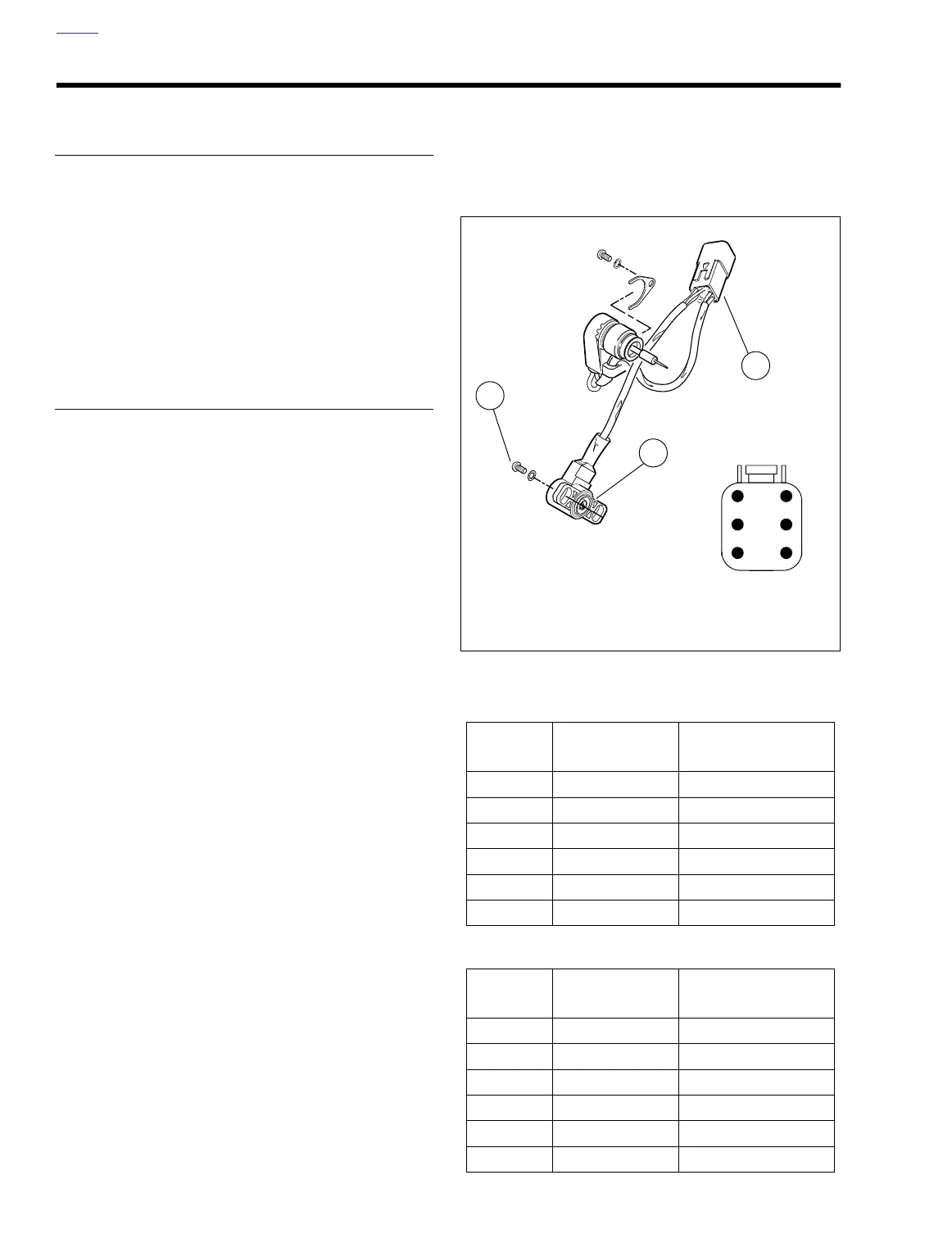

THROTTLE POSITION SENSOR (TP SENSOR) 7.4

GENERAL

See Figure 7-10. The throttle position sensor voltage deter-

mines which spark advance curve the ignition module

selects. The throttle position sensor (TP Sensor) is located on

the carburetor. The TP Sensor is not repairable. Replace the

unit if it fails.

See 4.6 THROTTLE POSITION SENSOR for information on

replacing the throttle position sensor.

See diagnostic chart on previous page for troubleshooting

information.

CALIBRATION/TESTING

NOTE

To gain access to the Throttle Position Sensor, remove the

carburetor and air cleaner as an assembly. See 4.4 CARBU-

RETOR and 1.17 AIR CLEANER.

1. Adjust throttle position sensor as follows:

a. Back off idle adjustment screw so throttle plate is

fully closed.

b. Completely open and close the throttle by rotating

the throttle control through its full range of motion.

c. Using special TORX bit (Snap-on

®

TTXR20E),

loosen the two tamper-resistant T20 TORX screws

just enough to allow sensor to rotate.

d. Separate connector [88] housings and remove

socket terminal from chamber 3 in connector [88B]

(main wire harness).

e. Install BREAKOUT BOX ADAPTORS (Part No. HD-

42962) and BREAKOUT BOX (Part No. HD-42682)

using black connectors between socket [88B] and

pin [88A] housings.

f. Turn ignition switch to ON. Using a multimeter, mea-

sure voltage between pin 3 (V/W) and pin 5 (BK).

g. Adjust (rotate) throttle position sensor (TPS) until

voltage reading is 0.5V +/- 0.05V.

h. Completely open and close the throttle by rotating

the throttle control through its full range of motion.

Wide Open Throttle (WOT) should not exceed 3.7V

and reading should increase consistently as throttle

is opened. If the voltage reading is erratic or the volt-

age reading at WOT exceeds 3.7V, see Figure 7-10.

for diagnostic testing.

NOTE

After WOT, the TPS reading may not return back to exactly

0.5V +/- 0.05V. To re-check exact TPS voltage reading, turn

cycle key off and on.

i. Tighten TP Sensor mounting screws to 13-23

in-lbs

(2-3 Nm).

2. Install carburetor and air cleaner. See 4.3 AIR

CLEANER.

3. Adjust idle speed. See 1.19 IGNITION TIMING AND

IDLE SPEED ADJUSTMENT.

Figure 7-10. Throttle Position Sensor

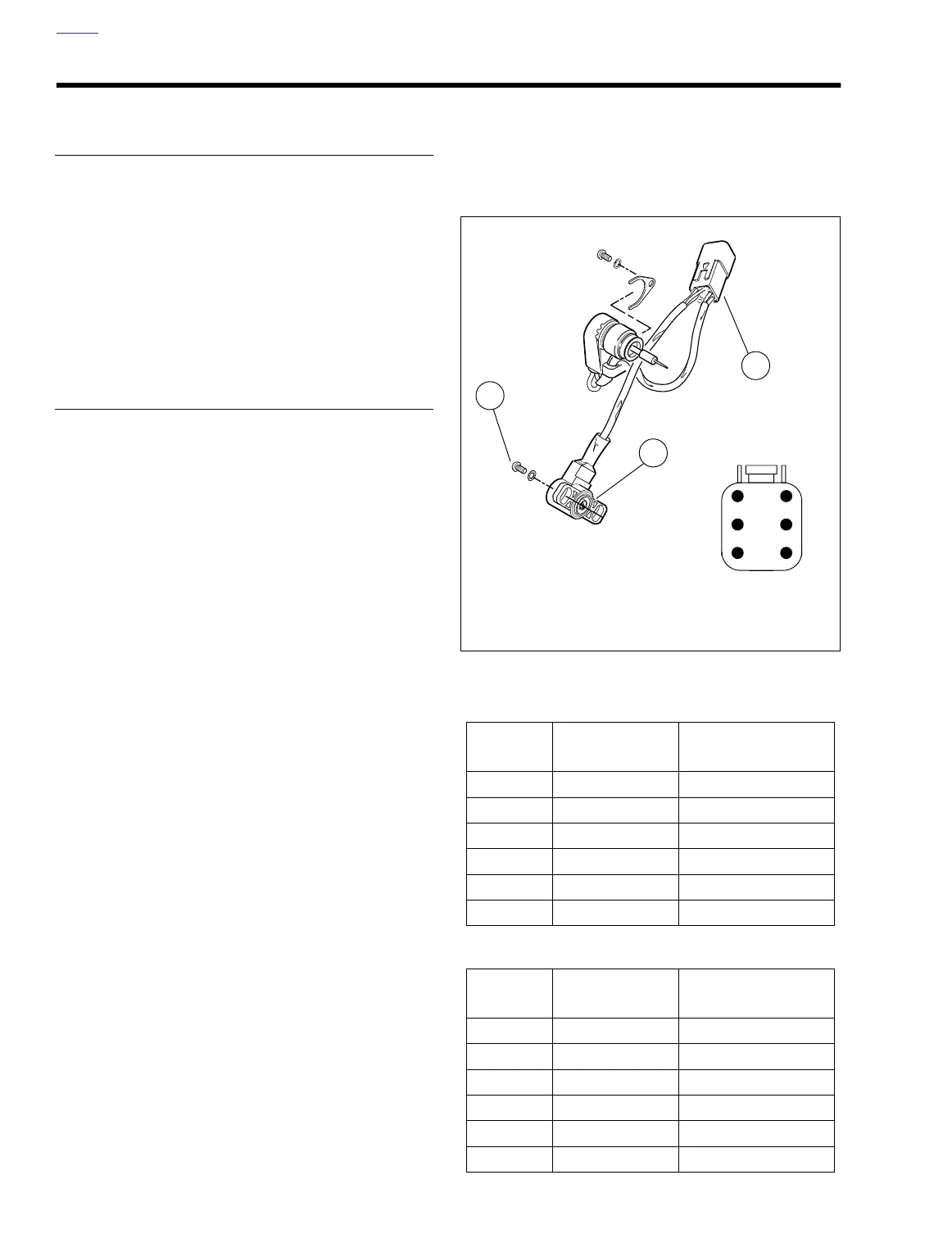

Table 7-10. Socket Housing [88B]

CHAMBER

NUMBER

WIRE COLOR FUNCTION

1 Violet/Orange Auto-Enrichener

2 Orange Auto-Enrichener

3 Violet/White TP Sensor Output

4 Violet/White TP Sensor Input

5 Black TP Sensor Ground

6 Not Used

Table 7-11. Pin Housing [88A]

CHAMBER

NUMBER

WIRE COLOR FUNCTION

1 Yellow Auto-Enrichener

2 Yellow Auto-Enrichener

3 Light Blue TP Sensor Output

4 Yellow TP Sensor Input

5 Black TP Sensor Ground

6 Not Used

a0225x7x

1

2

3

4

5

6

[88A]

a0223x7x

1. Connector pin housing [88A]

2. Throttle position sensor

3. Tamper-resistant T20 TORX screws

1

2

3

Loading...

Loading...