3-48

CRANKCASE

GENERAL

When rod bearings, pinion shaft bearing or sprocket shaft

bearing are in need of repair, the engine must be removed

from the chassis. See REMOVING ENGINE CRANKCASE

OR COMPLETE ENGINE on page 3-8. It is recommended

procedure to check and make repairs to cylinder heads, cylin-

ders, gearcase and transmission at the same time (perform

entire engine overhaul).

1

CAUTION

If engine is removed from chassis, do not lay engine on

primary side. Placing engine on primary side will damage

clutch cable end fitting. If fitting is damaged, clutch cable

must be replaced.

ADJUSTMENT/TESTING

Flywheel End Play

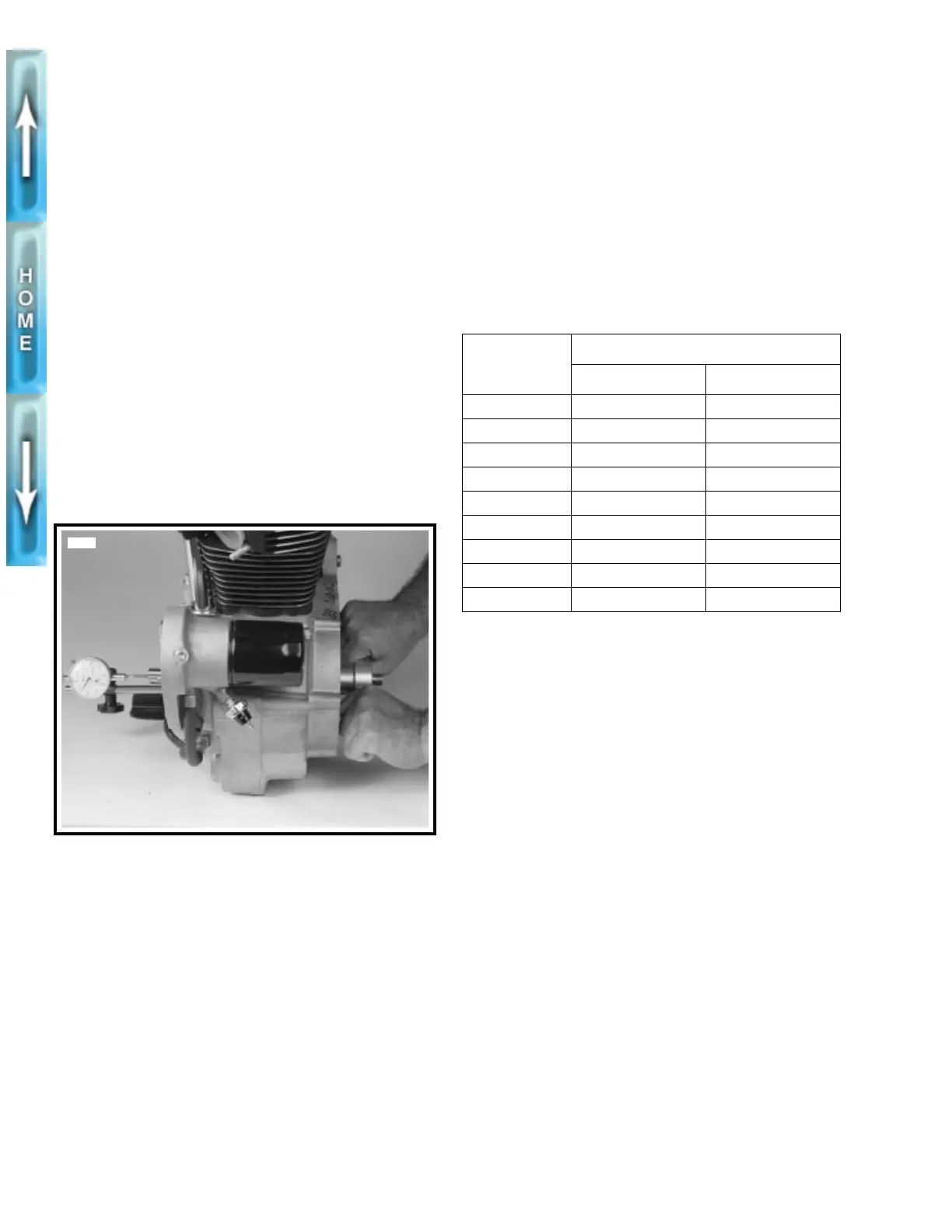

See Figure 3-64. Before completely disassembling crank-

cases, check flywheel end play.

1. After engine has been removed from chassis, securely

fasten it to a stand or workbench.

2. Remove gearcase cover. Attach a dial indicator to gear

side crankcase with indicator stem on end of gearshaft.

3. Sprocket shaft bearings must be preloaded to obtain an

accurate flywheel end play reading. A suitable tool can

be made by welding two handles to an old sprocket shaft

nut. Install the nut and sprocket. Tighten nut to 150-

165 ft-lbs (203-224 Nm).

4. Rotate and push on sprocket shaft while reading dial

indicator. Then rotate and pull on sprocket shaft while

reading dial indicator. If difference (end play) in indicator

readings is not 0.001-0.005 in. (0.025-0.13 mm), bearing

inner spacer (shim) (item 6, Figure 3-68.) must be

replaced. Choose spacer from Table 3-11. Use a thinner

spacer for less end play; use a thicker spacer for more

end play.

DISASSEMBLY

Crankcase Halves

1. Remove cylinder heads as described under CYLINDER

HEAD, REMOVAL on page 3-11.

1

CAUTION

After removing cylinders, install plastic or rubber hose

over cylinder studs. Lifting or moving crankcase by

grasping studs will cause cylinder stud damage.

2. Remove cylinders and pistons. See CYLINDER AND

PISTON, REMOVAL/DISASSEMBLY on page 3-22.

3. Remove oil pump as described under OIL PUMP,

REMOVAL/DISASSEMBLY on page 3-35.

4. Remove gearcase components. See GEARCASE

COVER AND CAM GEARS, REMOVAL/DISASSEMBLY

on page 3-40.

5. Remove clutch and primary drive components. See PRI-

MARY DRIVE/CLUTCH in Section 6.

Figure 3-64. Checking Flywheel End Play

3536a

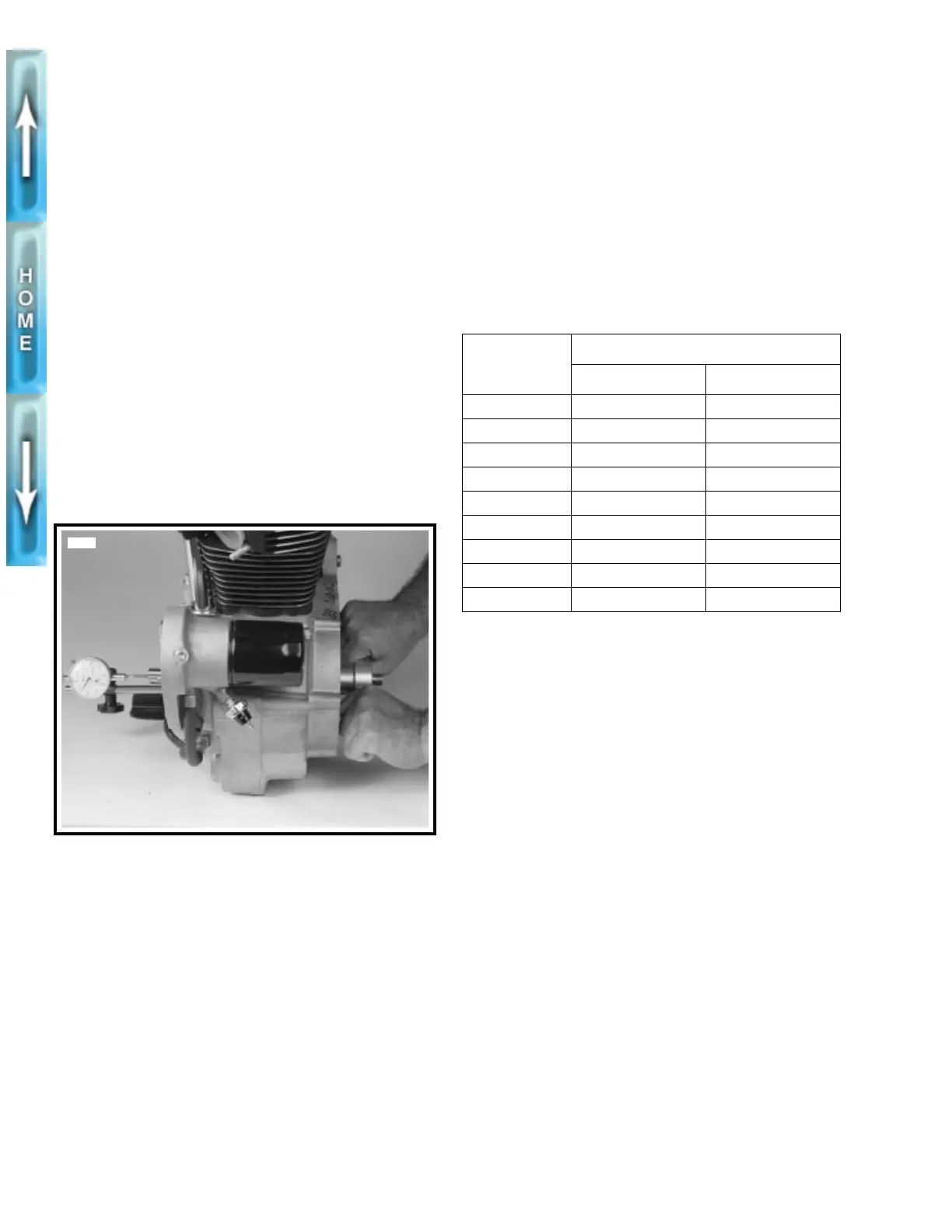

Table 3-11. Flywheel End Play

Spacers (Shims)

PART

NUMBER

THICKNESS

IN. MM

9155 0.0975-0.0985 2.476-2.502

9142 0.0995 - 0.1005 2.527-2.553

9143 0.1015-0.1025 2.578-2.603

9144 0.1035 - 0.1045 2.629-2.654

9145 0.1055 - 0.1065 2.680-2.705

9146 0.1075 - 0.1085 2.730-2.756

9147 0.1095 - 0.1105 2.781-2.807

9148 0.1115 - 0.1125 2.832-2.857

9149 0.1135 - 0.1145 2.883-2.908

Loading...

Loading...