7-MAINTENANCE

Enginecoolingsystem

OrganicidAcidTechnology(OAT)coolant

CASECONSTRUCTIONrequirestheuseofafullyformulatedOrganicAcidTechnology(OAT)basedcoolant.CASE

AKCELAACTIFULL™OTEXTENDEDLIFECOOLANTispreferred.Thecoolantmustmeetthespecications

outlinedintheCNHIndustrialmaterialspecicationMAT3624.Useofcoolantnotmeetingthisspecicationisnot

allowed.Mixingofdifferentcoolantbrandsisnotrecommended.

NOTICE:OATcoolantismandatoryforallFPTenginescomplianttoTIER4BemissionsusingSelectiveCatalytic

Reduction(SCR).NEVERmixOATcoolantwithconventionalcoolant.Undernocircumstancesshouldyoutopoffa

coolingsystemwithonlywater.Youcanusearefractometertochecktheconcentrationlevel.Youshouldnotuse

SupplementalCoolantAdditives(SCA)whenusingCASEAKCELAACTIFULL™OTEXTENDEDLIFECOOLANT.

Changethecoolantsolutionattherecommendedchangeinterval.

NOTE:mixtheCASEAKCELAACTIFULL™OTEXTENDEDLIFECOOLANTwith50%ofcleanwater.Waterfor

dilutionofOATcoolantconcentrate:distilledordemineralized.Ifdemineralizedwaterisnotavailable,usewaterfor

dilutionwiththefollowingproperties:

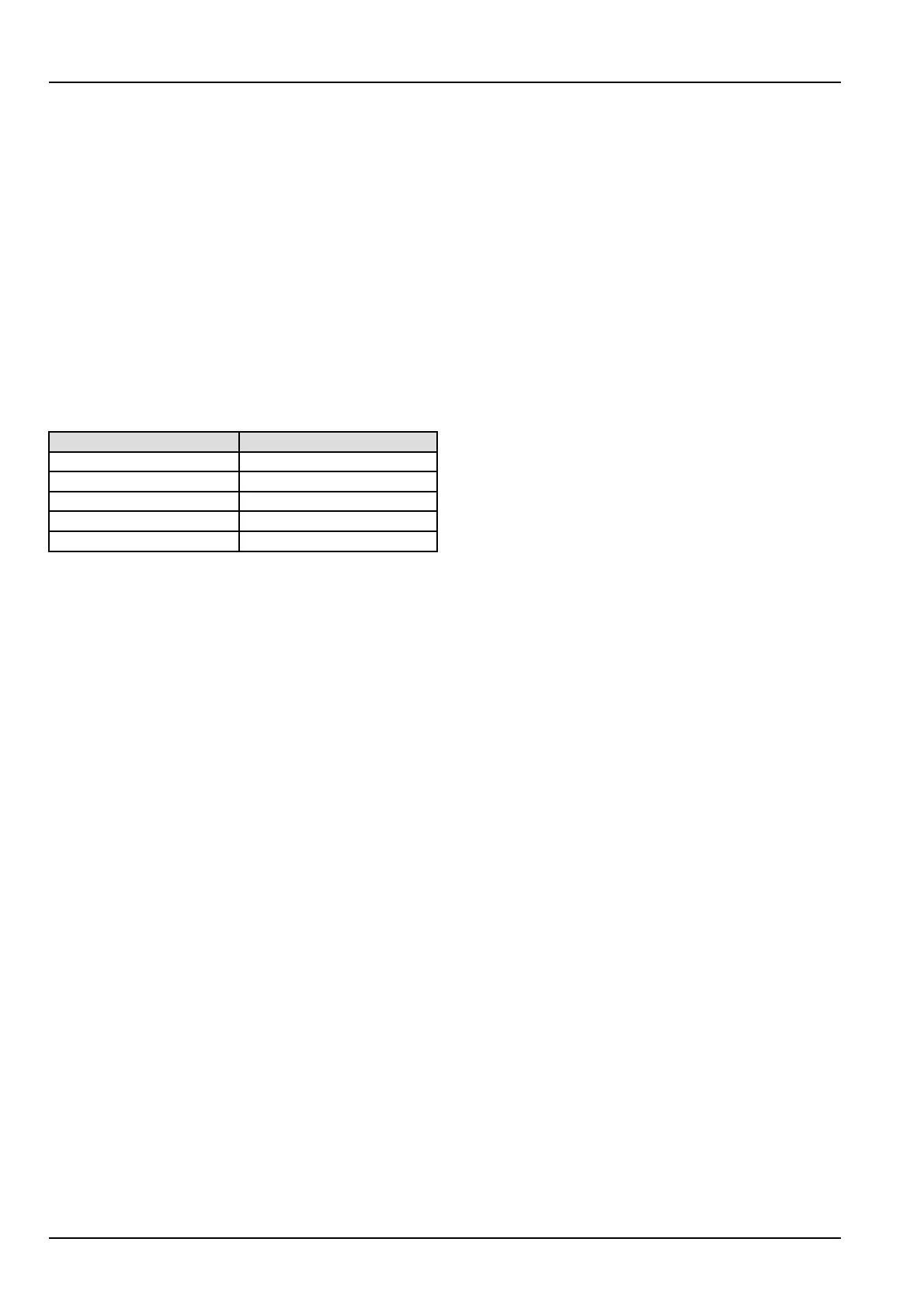

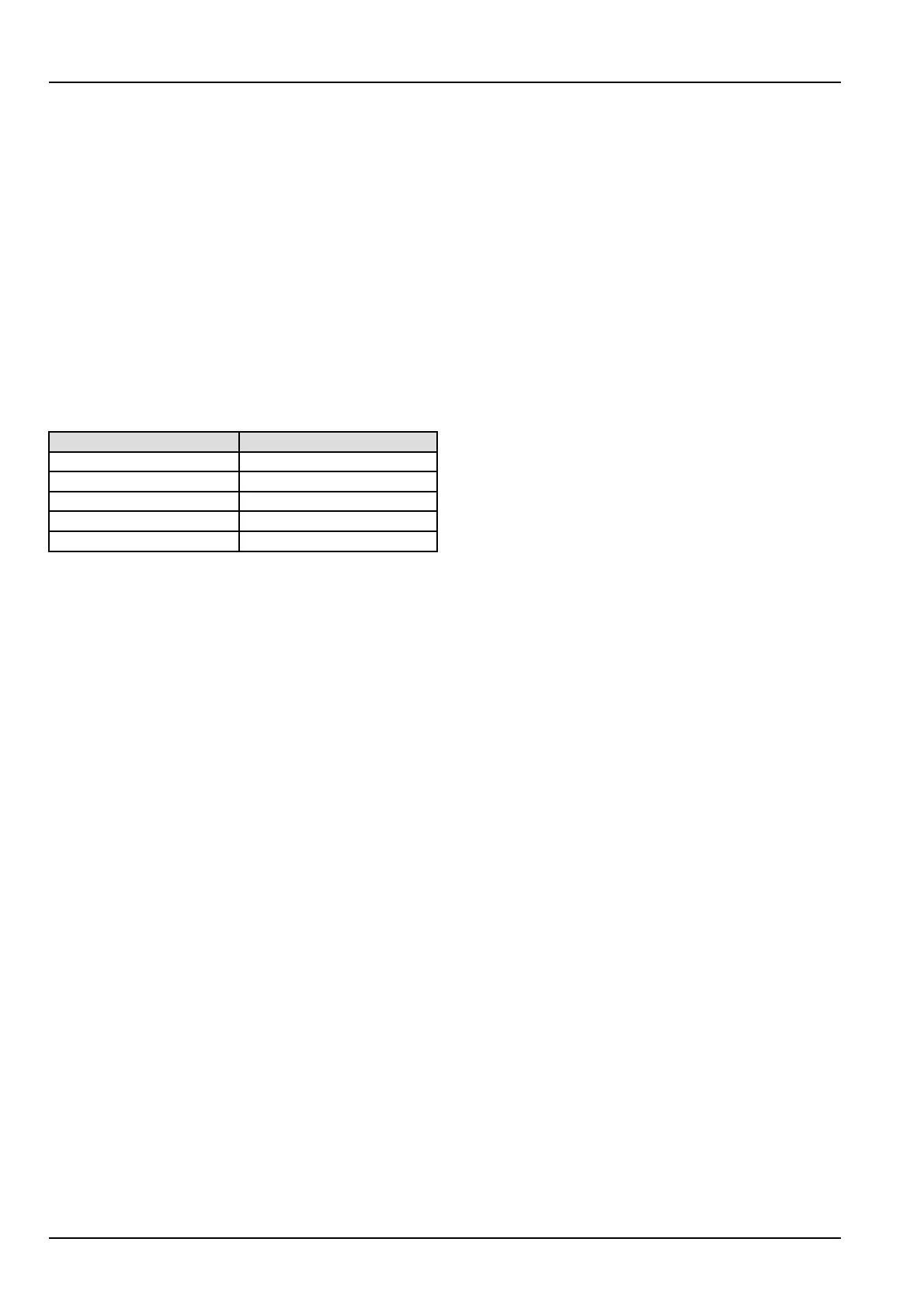

PropertyMaximumlimit

TotalSolids

340ppm

TotalHardness170ppm

Chloride(Cl)

40ppm

Sulfate(SO4)

100ppm

AciditypH5.5to9.0

Thissolutionensuresprotectionofthecircuitfrom-40.0°C(-40.0°F)to125.0°C(257.0°F).

Theoptimumcoolant/waterconcentrationis50/50.Thisconcentrationwillprotectthecoolingsystemto-37°C

(-35°F).Ifapremixedcoolantisnotavailable,mixtheconcentratewith50%ofwater.Thecoolantconcentrationin

thecoolant/watermixturecanbedeterminedwitharefractometerdesignedtomeasureethyleneglycolcontent.

Distilledwaterordeionizedwaterisrecommendedfortheuseintheenginecoolingsystems.

DONOTusehardwater,seawaterand,softenedwaterseathathasbeenconditionedwithsalt.Themineralsand

saltspresentinpotablewatercancausecorrosionanddepositsresultinginshortenedenginelife.

InthecasethatthecustomermayhavetoppedoffanOATcoolantsystemwithconventionalcoolant,followthe“Wash-

ingofthecoolingsystem”onthenextpagetoattainthefullbenetofthecoolant.

7-14

Loading...

Loading...