7-MAINTENANCE

Initial100hours

Wheelnutstightening-Check

WARNING

Explosionhazard!

Neverweldonawheel.Weldingcancausestressesthatwillcauseawheeltocrackorbreakunexpect-

edly.Tirescanseparateexplosivelyduringwelding.Alwayshaveaqualiedtiremechanicservice

wheelsandtires.

Failuretocomplycouldresultindeathorseriousinjury.

W0124A

Tireorrimservice

Alwayshaveaqualiedtiretechnicianservicethetires

andrimsforthismachine.Itisrecommendedthatyou

havethistechnicianinatethetires.T opreventacci-

dents,usearestrainingdevice(tireinationcage),cor-

rectequipment,andcorrectprocedure.

Explosiveseparationofthetire(singlepiecerim),orthe

tireand/orrimparts(multi-piecerim)cancauseserious

injuryordeath.

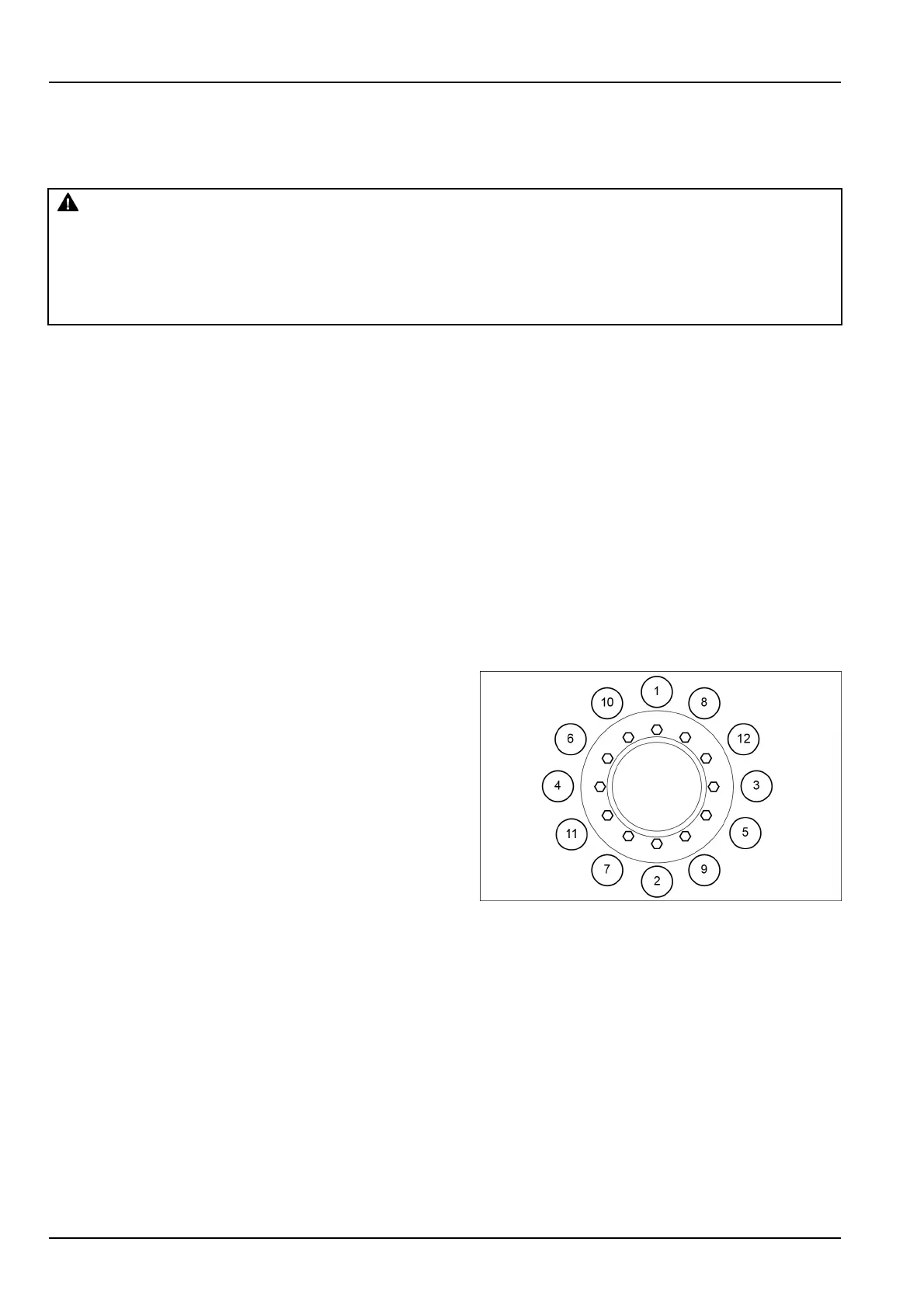

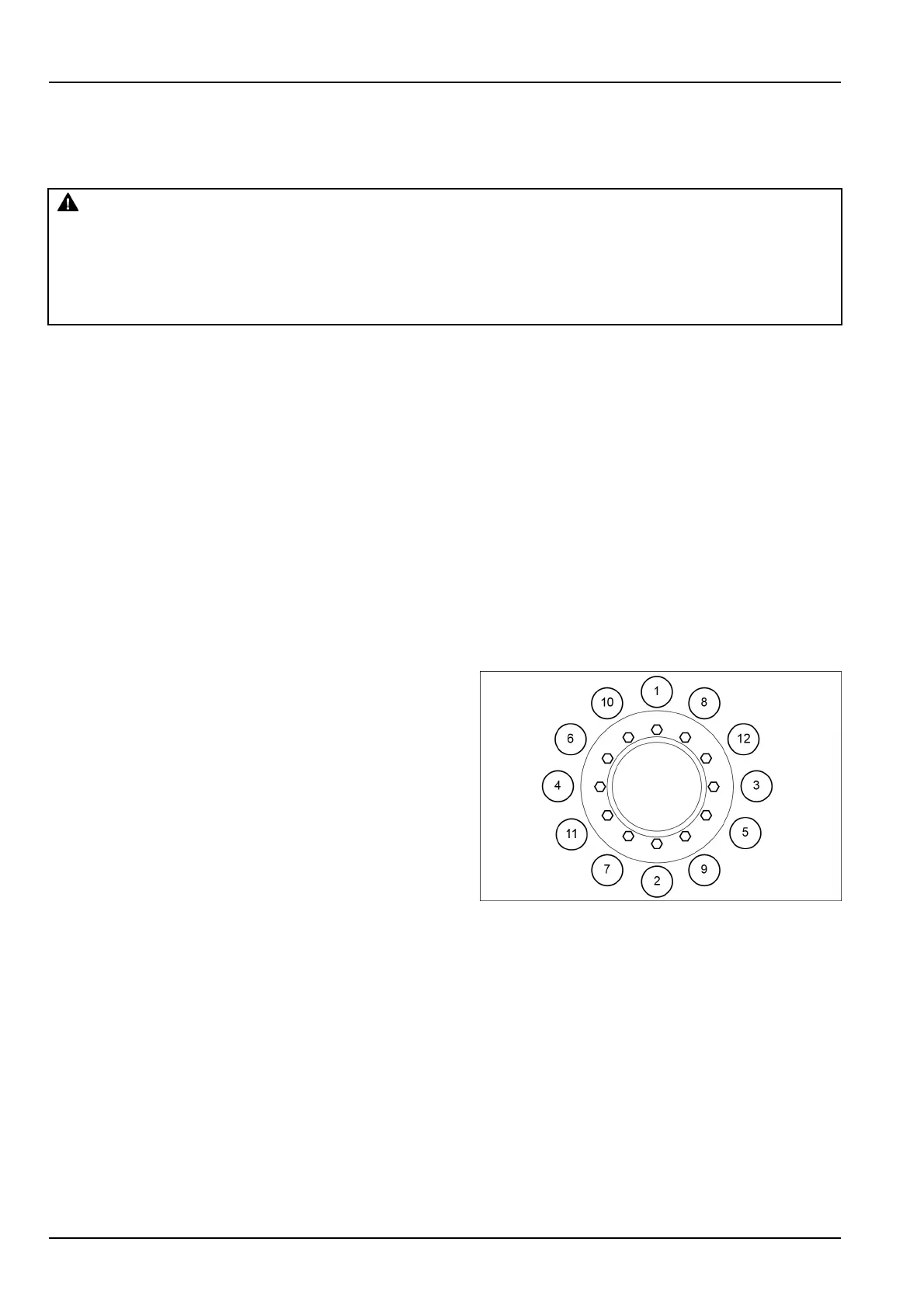

Studmountedwheels(ifequipped)

Machinesequippedwithoptionalheavydutyaxleshave

astudmountedwheel.TheHeavyDuty(HD)axlein-

corporatesastudandnutassembly.

Wheelbolttorque

Ifnecessary,tightenthewheelnutstotherequired

torque.

Useahandwrench(notanimpact)totightenthewheel

boltstopullthewheelagainsttheplanetaryhousing.

Tightenthewheelboltsusingthesequenceshown.

Firsttightentheboltsto278N·m(205.0lbft),then

tightentoanaltorqueof640–720N·m(472.0–

531.0lbft),usingthesamesequence.

LEIL15WHL1848AB1

7-50

Loading...

Loading...