2-SAFETYINFORMATION

Supportstrutandservicelink

Supportstrut

WARNING

Crushinghazard!

Ifyouservicethemachinewiththeloaderliftarmsraised,alwaysusethesupportstrut.Removethe

supportstrutfromthestoragepositionandplacethestrutontothecylinderrod.Installtheretaining

boltentirelyintothestrut.Lowerliftarmsontothesupportstrut.

Failuretocomplycouldresultindeathorseriousinjury.

W0140A

Ifyouservicethemachinewiththeloaderliftarmsraised,alwaysusethesupportstrut.

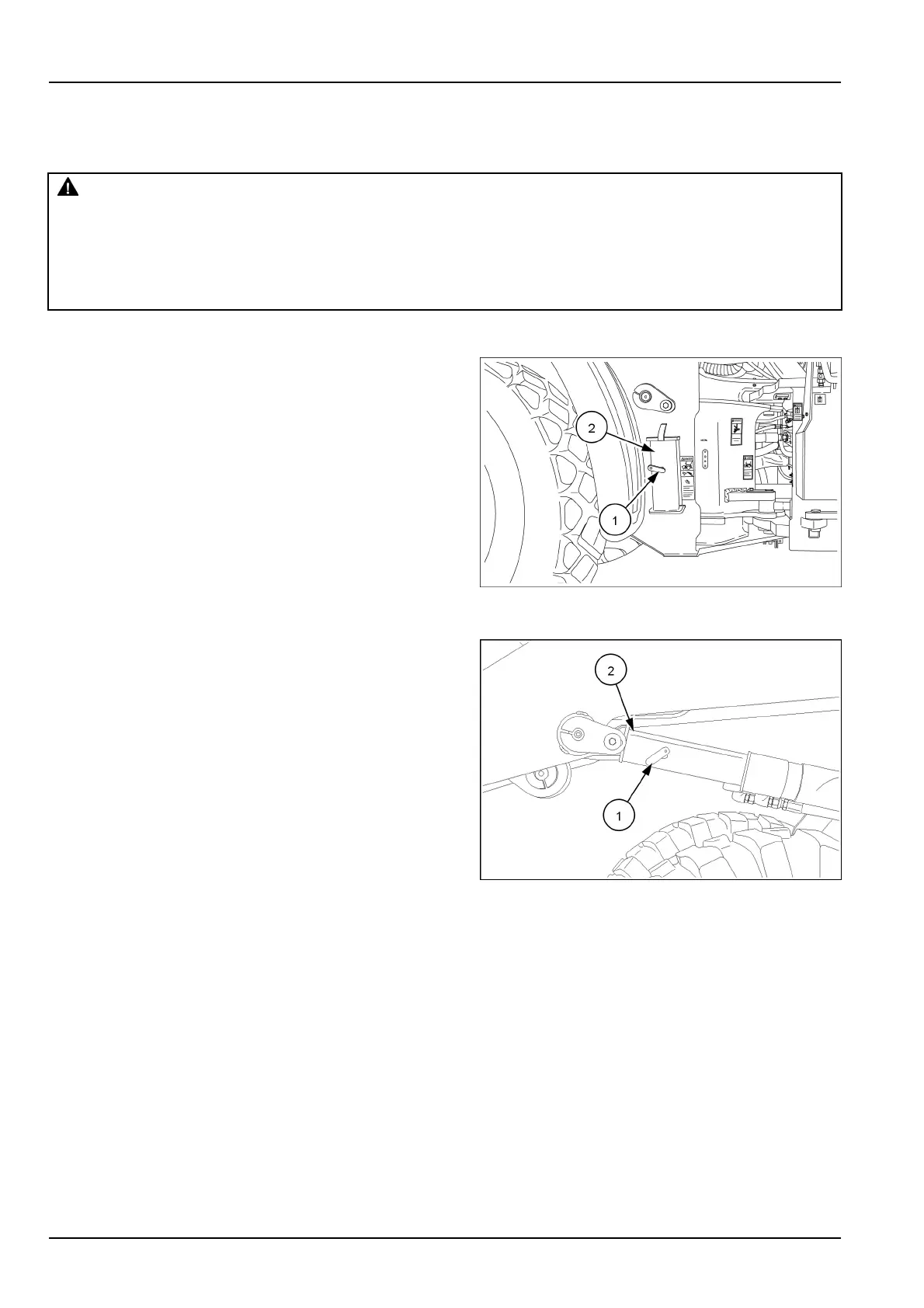

1.Emptytheloaderbucket,raisetheloaderliftarmsto

approximately2.1m(7ft)andstoptheengine.

2.Maintainthebucketinadumpedposition.Remove

theretainingbolt(1).Removethesupportstrut(2)

fromthestorageposition.

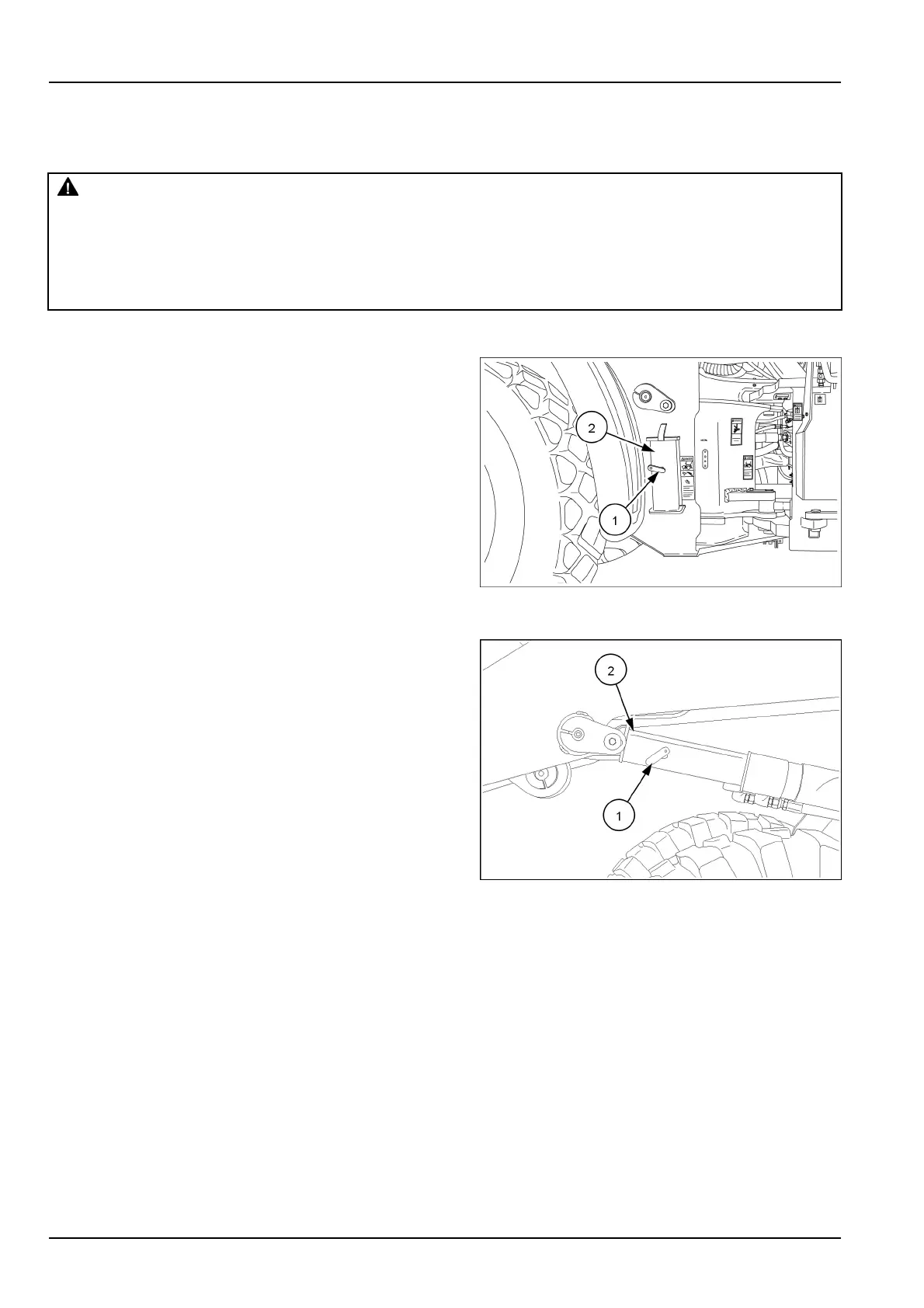

3.Placethesupportstrut(2)onthecylinderrodwiththe

guidelocktabontopofcylinderandpointingtoward

thebucket.

4.Installtheretainingbolt(1)entirelyintothesupport

strut(2)usingallthreads.

5.Slowlylowertheliftarmsontothesupportstrut.Main-

tainthebucketinadumpedposition.

LEIL15WHL1850AA1

NOTE:supportstrutintransportposition.

RCPH10WHL061BAL2

NOTE:supportstrutinserviceposition.

Ifyoudonotfollowthisprocedure,youcancausedeathorseriousinjuryiftheloaderliftarmsareloweredunexpect-

edly.

2-12

Loading...

Loading...