SECTION 5

5-18

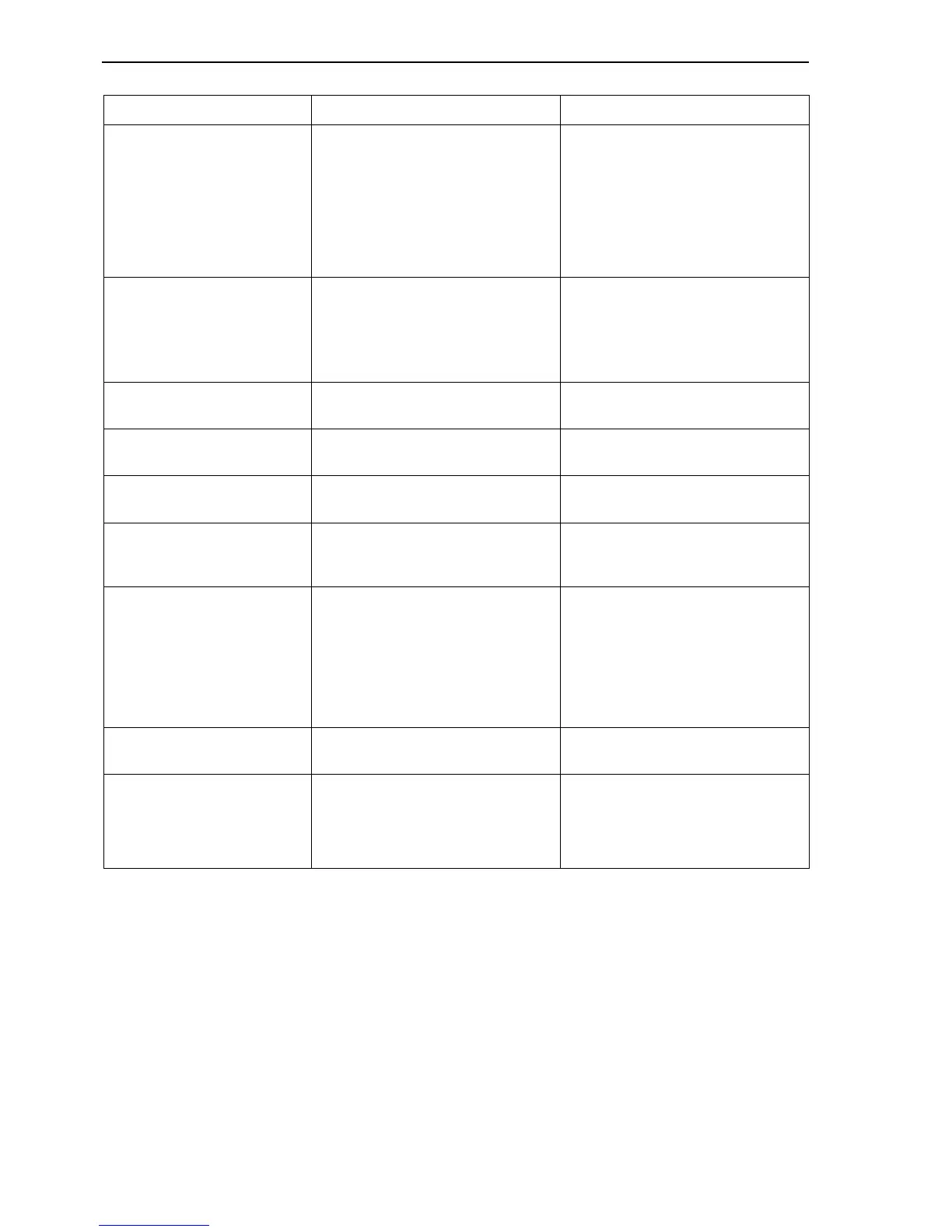

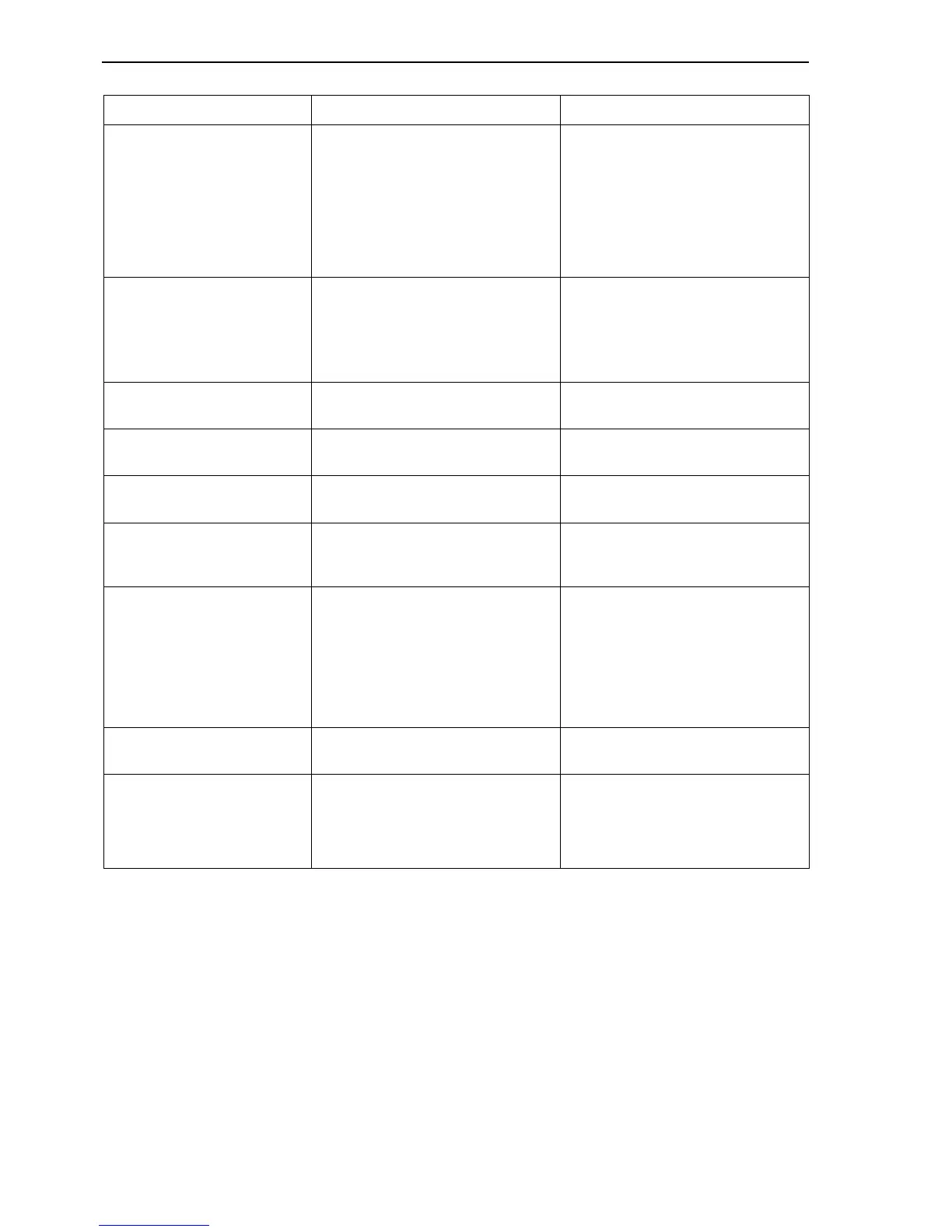

Oil leakage from gaskets and

seals.

Prolonged functioning at high

temperature of the oil.

Replace the gasket or seal and

matching surface if damaged.

Oil gasket assembled incorrectly. Replace.

Damaged or worn gasket lip. Replace.

Contaminated oil. Use correct lubricants and replace at

recommended intervals.

Excessive wear of input flange

spline.

Excessive use. Replace the flange.

Pinion nut loose. Tighten pinion nut.

Excessive pinion axial backlash. Check and adjust the backlash.

Pinion teeth cracked because

of the fatigue.

Excessive use or continuous

overload.

Replace bevel gear.

Break of pinion and ring gear

teeth.

Crash load of differential

components.

Check and/or replace other

differential components.

Side gear spline worn out. Excessive use. Replace differential gear assy.

Replace axle beam, if necessary.

Thrust washer surface worn

out or scratched.

Insufficient lubrication.

Incorrect lubrication.

Contaminated oil.

Use a correct lubricant, top up to

correct level and replace washers.

Inner diameter of tapered roller

bearings worn out.

Excessive use. Replace bearing.

Excessive pinion axial backlash. Check pinion axial backlash.

Insufficient lubrication.

Contaminated oil.

Use proper lubrication, fill up to right

level and replace at recommended

intervals.

Bent or broken axle beam. Vehicle intensively operated or

overloaded.

Replace.

Axle beam broken at wheel

side.

Wheel support loose. Replace.

Axle beam body bent. Ensure that wheel support is not worn

out or wrongly adjusted.

PROBLEM POSSIBLE CAUSE CORRECTION

Loading...

Loading...