ENGLISH

84

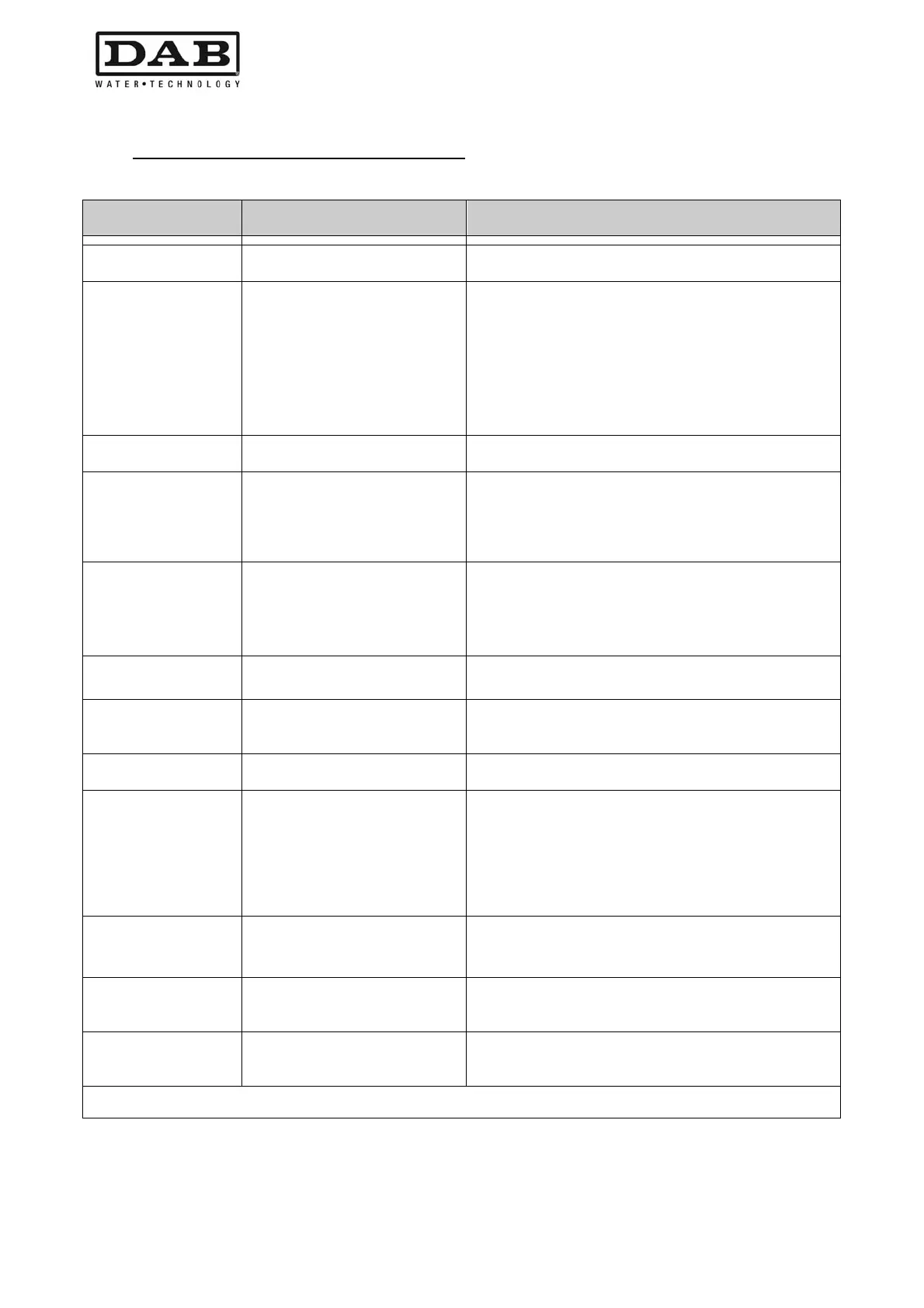

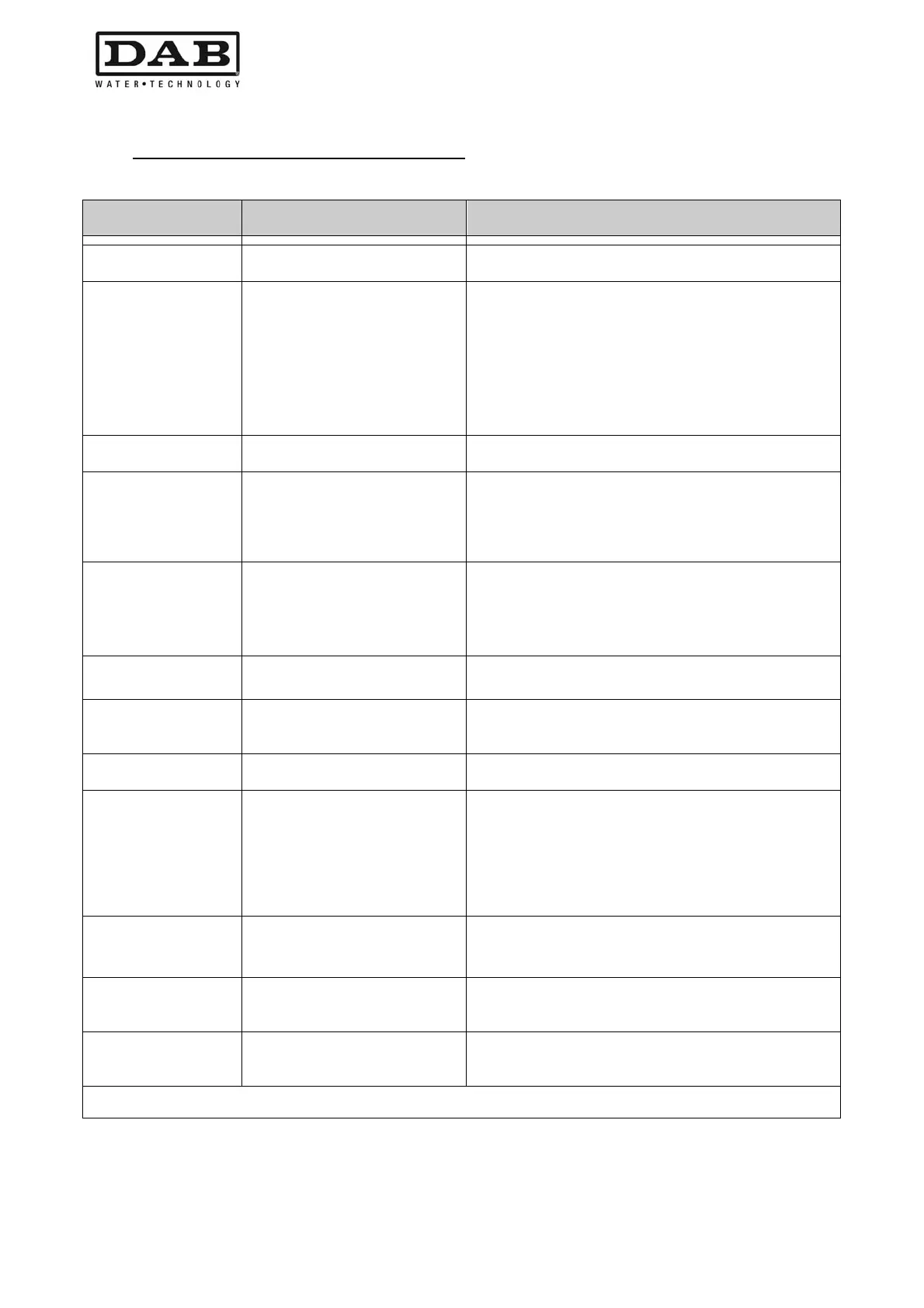

5.2 Troubleshooting on initial installation

Fault Possible causes Remedy

The display shows

EC

Pump current (RC) not set

Set parameter RC (see section

6.5.1).

The display shows

BL

1) No water.

) Pump not primed.

3) Flow sensor disconnected.

) Entry of setpoint too high for pump.

5) Inverted direction of rotation.

6) Incorrect setting of pump current

RC(*).

7) Maximum frequency too low (*).

1-2) Prime the pump ad ensure that there is no air in the

pipelines. Check that intake or any filters are not obstructed

Check that the pipeline from the pump to the inverter is not

damaged or leaking.

3) Check the connections to the flow sensor.

4) Lower the setpoint or use a pump suited to system

requirements.

5) Check the direction of rotation (see

6.5.2).

6) Set a correct value for pump current RC(*) (see

6.5.1).

7) If possible, increase FS or lower RC(*) (see

6.6.6).

The display shows

BP1

1) Pressure sensor disconnected.

2) Pressure sensor faulty.

1) Check the pressure sensor cable connection.

2) Replace the pressure sensor.

The display shows

OF

1) Excessive absorption.

) Pump blocked.

3) Pump absorbs high current on start-

up.

1) Check type of connection; star or delta. Check that the motor

does not absorb current over the max. admissible value for

inverter. Check that the motor has all phases connected.

2) Check that the impeller or motor is not blocked or obstructed by

foreign bodies. Check motor phase connections

3) Reduce the acceleration parameter AC (see

6.6.11).

The display shows

OC

1) Incorrect pump current setting (RC).

) Excessive absorption.

3) Pump blocked.

) Inverted direction of rotation.

1) Set RC with the current according to the type of connection

(star or delta) as stated on the motor dataplate (see

6.5.1)

2) Check that the motor has all phases connected.

3) Check that the impeller or motor is not blocked or obstructed by

foreign bodies.

3) Check the direction of rotation (see

6.5.2).

The display shows

LP

1) Low power supply voltage

) Excessive voltage drop on line

1) Ensure presence of correct line voltage.

2) Check the power cable section

(see section 2.2.1).

Regulation

pressure greater

than SP

FL setting too high

Reduce minimum operating frequency FL (if electric pump

enables this)

The display shows

SC

Short circuit between phases

Ensure that the motor is in the correct condition and check

connections to the latter

The pump never

stops

1) Minimum flow threshold FT setting

too low.

) Short observation time(*).

3) Unstable pressure regulation(*).

) Incompatible use (*).

1) Set a higher FT threshold

2) Wait for ½ day for self-learning process (*) or implement quick

learning process (see

6.5.9.1.1)

3) Correct GI and GP(*) (see

6.6.4 and 6.6.5)

4) Ensure that the system meets the operating requirements

without the flow sensor (*) (see section

6.5.9.1). Attempt to reset

by pressing MODE SET + - to recalculate conditions without the

flow sensor.

The pump stops

even when not

required

1)Short observation time(*).

) Minimum frequency FL setting too

high (*).

1) Wait for ½ day for self-learning process (*) or implement quick

learning process (see section

6.5.9.1.1).

2) If possible set a lower FL value(*).

The multi inverter

system does not

start

One or more inverters have an

incorrect RC current setting.

Check the RC current setting on each inverter.

The display shows:

Press + to align this

config

One or more inverters have sensitive

parameters not aligned

Press + on the inverter that has the most recent and correct

configuration of parameters.

(*) The asterisk refers to cases of systems without the flow sensor

Table 12: Troubleshooting

Loading...

Loading...