. . . . .

MAINT/DIAG SCREENS

PID Tuning

2-9317-372-00-0 Bravo™ 8105 Programming and Operations Guide 10-107

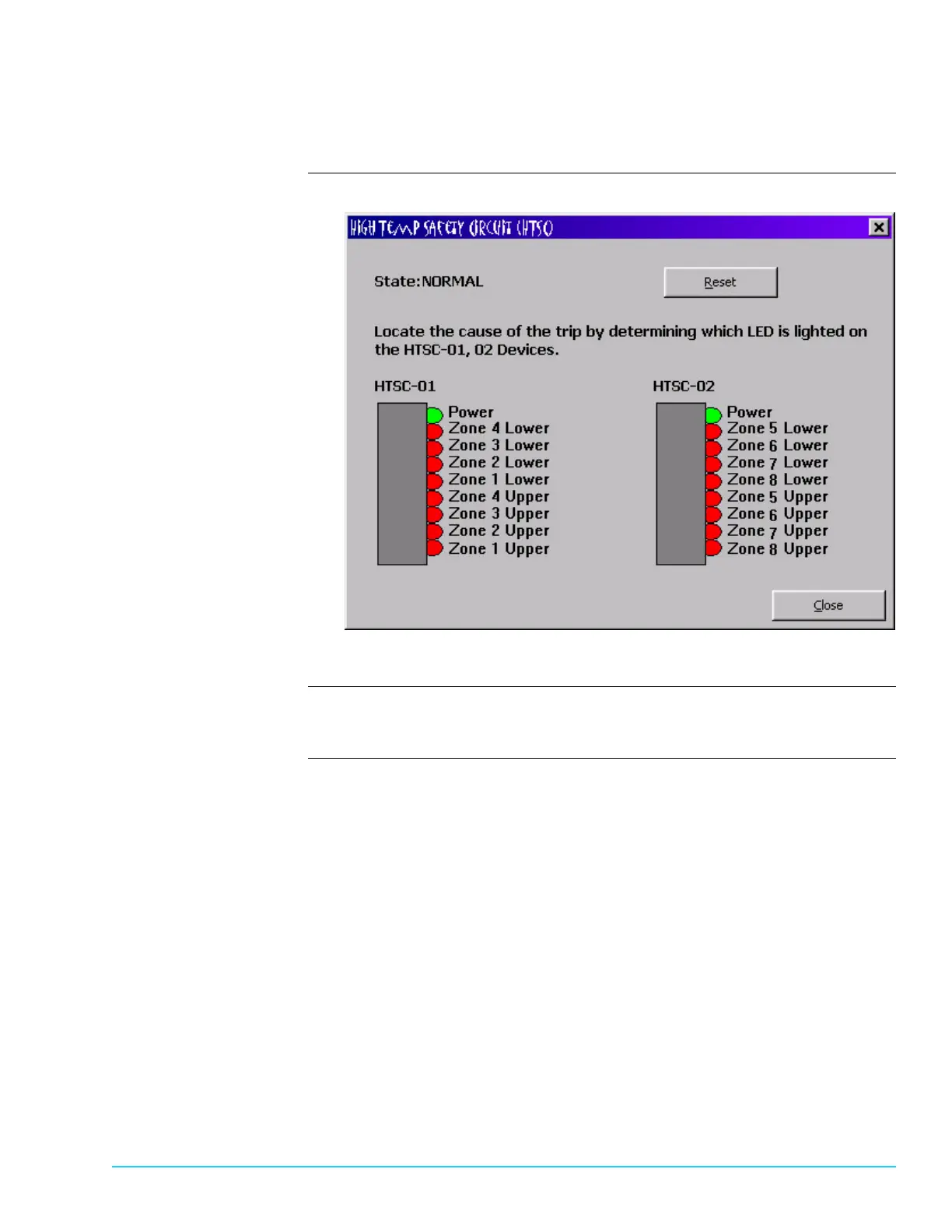

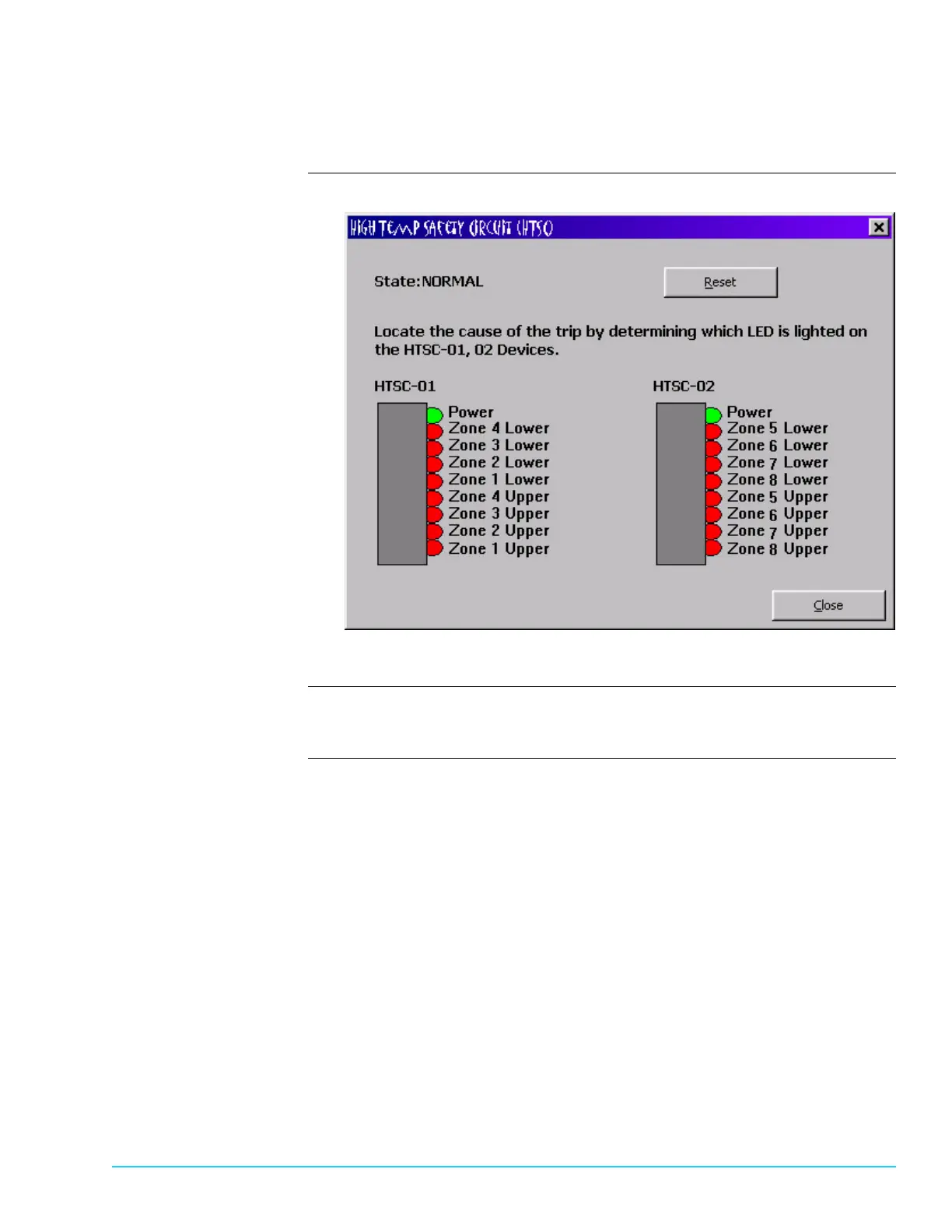

Note that the Bravo™ cannot operate until the Thermal Runaway High

Temperature Safety circuit is Reset.

Photograph

Figure 10–3

PID Tuning

Closed Loop Feedback PID is an acronym for Proportional–Integral–Derivative. Proportional measures the

difference between the measured value and the setpoint value. The controller

output is proportional to a change in measurement. Integral refers to the

controller producing a signal that is determined by the length of time the error

signal is present. (The error signal is produced when the measured value differs

from the setpoint value.) Derivative refers to the controller producing a signal that

is determined by the rate of change in the error signal, i.e., how much time it

takes the measured value to increase or decrease a given amount.

PID Tuning is preset at the factory. The factory defaults for the PID values that

are specific to the machine are shipped with the machine documentation. Only a

technician trained and authorized to perform PID tuning should alter any of the

values.

PID is used for closed loop feedback to accurately control machine components.

It generates an output that applies a corrective effect to the process so that it

drive the (measurable) process variable, in this case, temperature or speed,

toward the setpoint value.

Loading...

Loading...