1-10 General Information Rev. E

2. Notes on slip/validation paper

• The paper must be flat, without curls or wrinkles, especially at the top edges.

Otherwise, the paper may rub against the ribbon and become dirty.

• Insert a validation from the upper side in the validation entrance of the case opening. If

the validation is inserted sliding from the left to the right, the print position may be

incorrect since the paper can be crooked or the validation sensor can detect incorrectly.

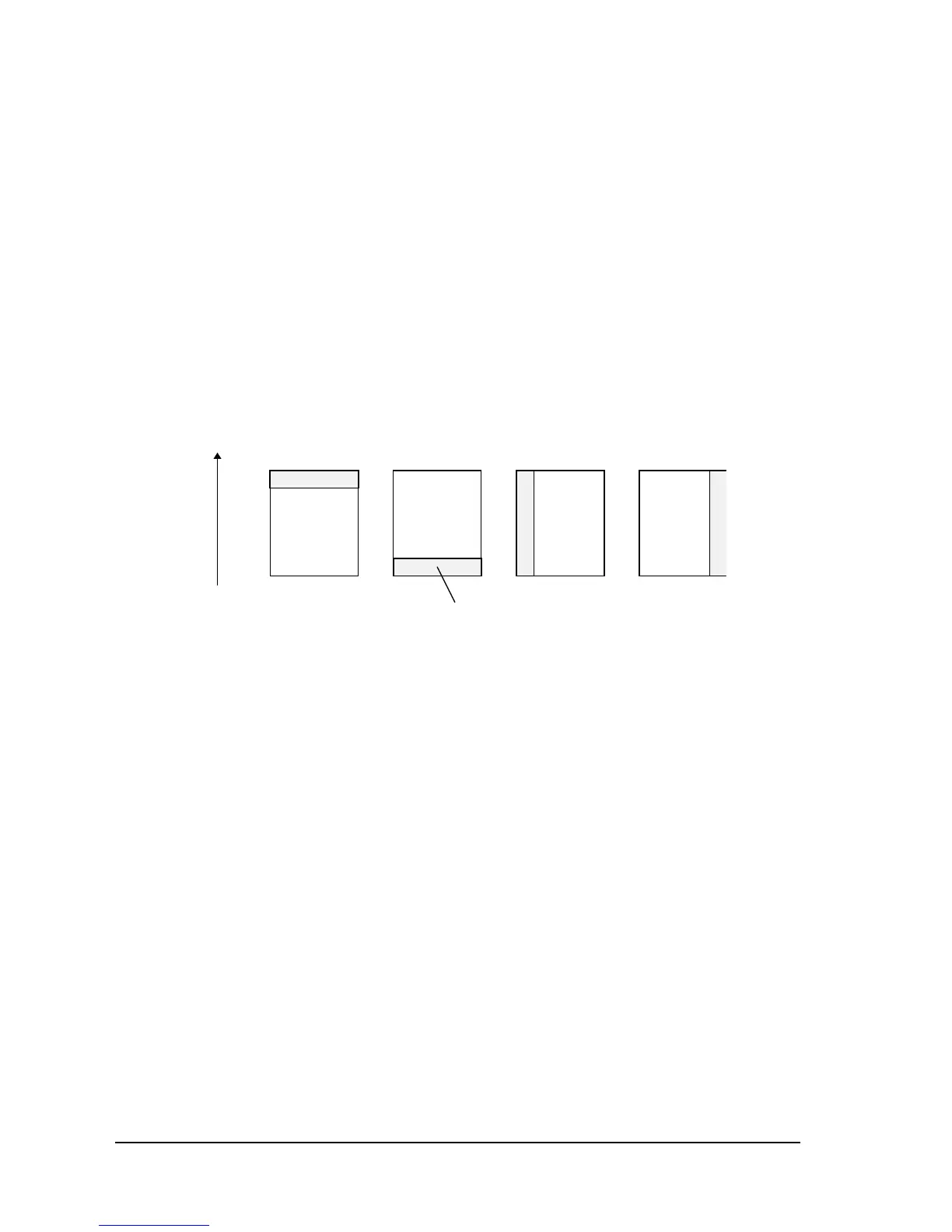

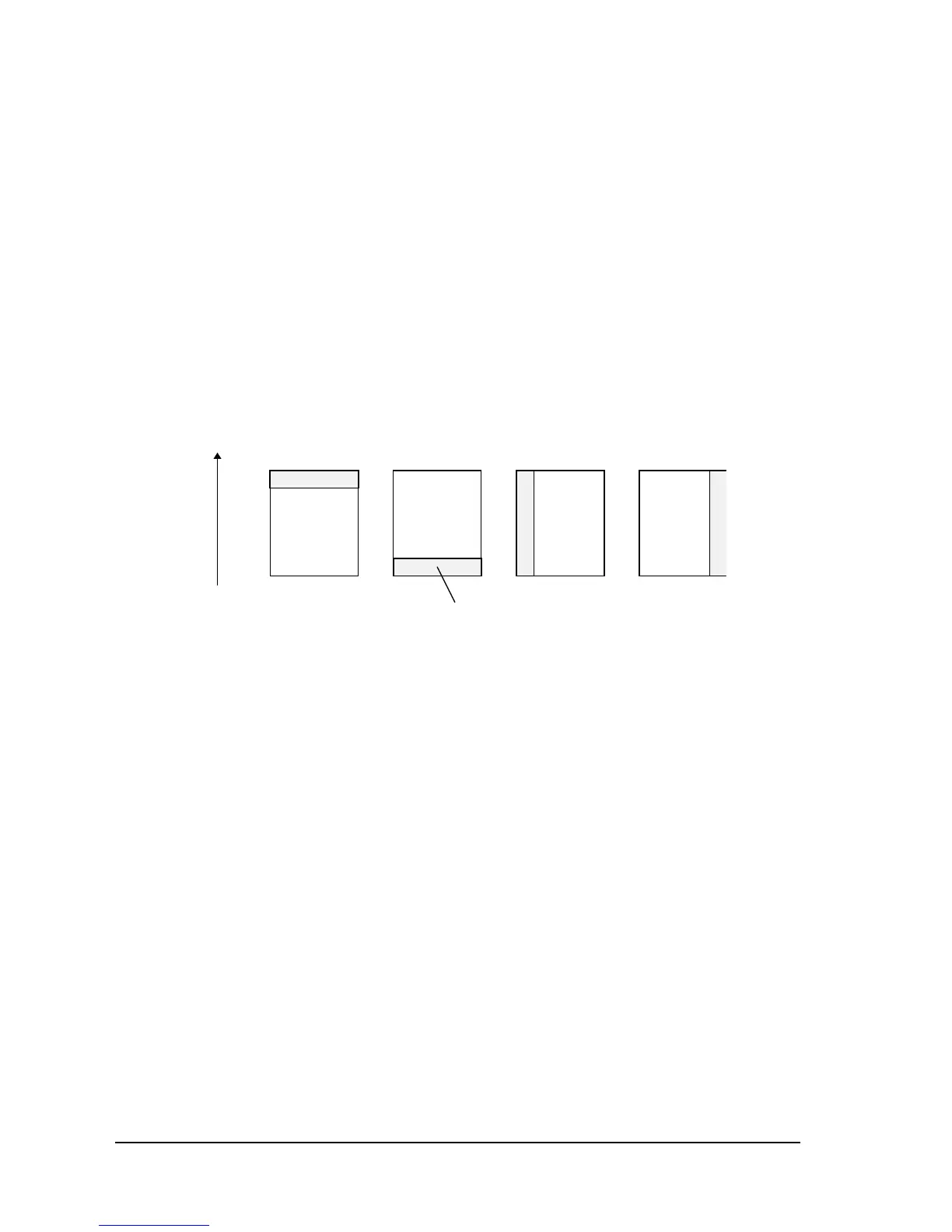

• There must be no glue on the bottom edge of paper. Choose paper carefully when the

glue is on the right or top edge, since paper feeding and insertion are affected by gluing

conditions (e.g., glue quality, method, and length) and glue location (refer to the figure

below). Be especially careful when paper is wide and has the glue on the left edge, since

skew may occur.

Slip (validation) paper glued area

• Since the slip BOF sensor uses a photo sensor, do not use paper that has holes at the

sensor position, or is translucent.

• Since the slip TOF sensor and validation sensor use a reflective photo sensor and it

detects from the back of slip paper, do not use paper that has holes or dark portions with

low reflection (less than 40% reflection) at the sensor position.

• Since the slip paper ejection sensor uses a reflective photo sensor and it detects from the

surface of the paper roll, do not use paper that has holes or dark portions with low

reflection (less than 40% reflection) at the sensor position.

Paper feed

direction

Glued area

Use carefullyUse carefullyDo not use

OK to use

Loading...

Loading...