ST100A Series Flow Meter INSTALLATION

Fluid Components International LLC 7

2 INSTALLATION

Specific Conditions of Use

1. Consult the manufacturer if dimensional information on the flameproof joints is necessary.

2. The painted surface of the ST100A Series Flow Meter may store electrostatic charge and become a source of ignition in applications

with a low relative humidity < 30% relative humidity where the painted surface is relatively free of surface contamination such as dirt,

dust, or oil. Cleaning of the painted surface should only be done with a damp cloth.

3. Do not replace internal battery when an explosive gas atmosphere is present.

4. Refer to Appendix D, page 152, for details on the relationship between the temperature class, the maximum surface temperature, the

ambient temperature and the process temperature.

Instrument Identification and Outline Dimensions

APPENDIX A starting on page 105 provides outline dimensions and mounting bracket dimensions for all integral and remote mounted electronic

configurations. Verify all dimensions meet the application requirements before beginning the installation process.

ST100A Insertion Sensor Installation

The proper flow meter location in the process piping configuration is critical to the instrument’s ability to measure the process variables accurately.

FCI recommends 20 nominal pipe diameters upstream and 10 pipe diameters downstream of the instrument installation point for most applications.

These distances can be significantly reduced when the flow meter is combined with FCI’s flow conditioning technology (Vortab).

Insertion flow elements can be mounted into the process using several available customer selectable configurations; compression fitting mounted,

threaded or flanged packing gland mounted, and threaded or flanged fixed “U” length mounted process connections. The specific sensor process

connection is specified by the customer on the order information sheet (OIS).

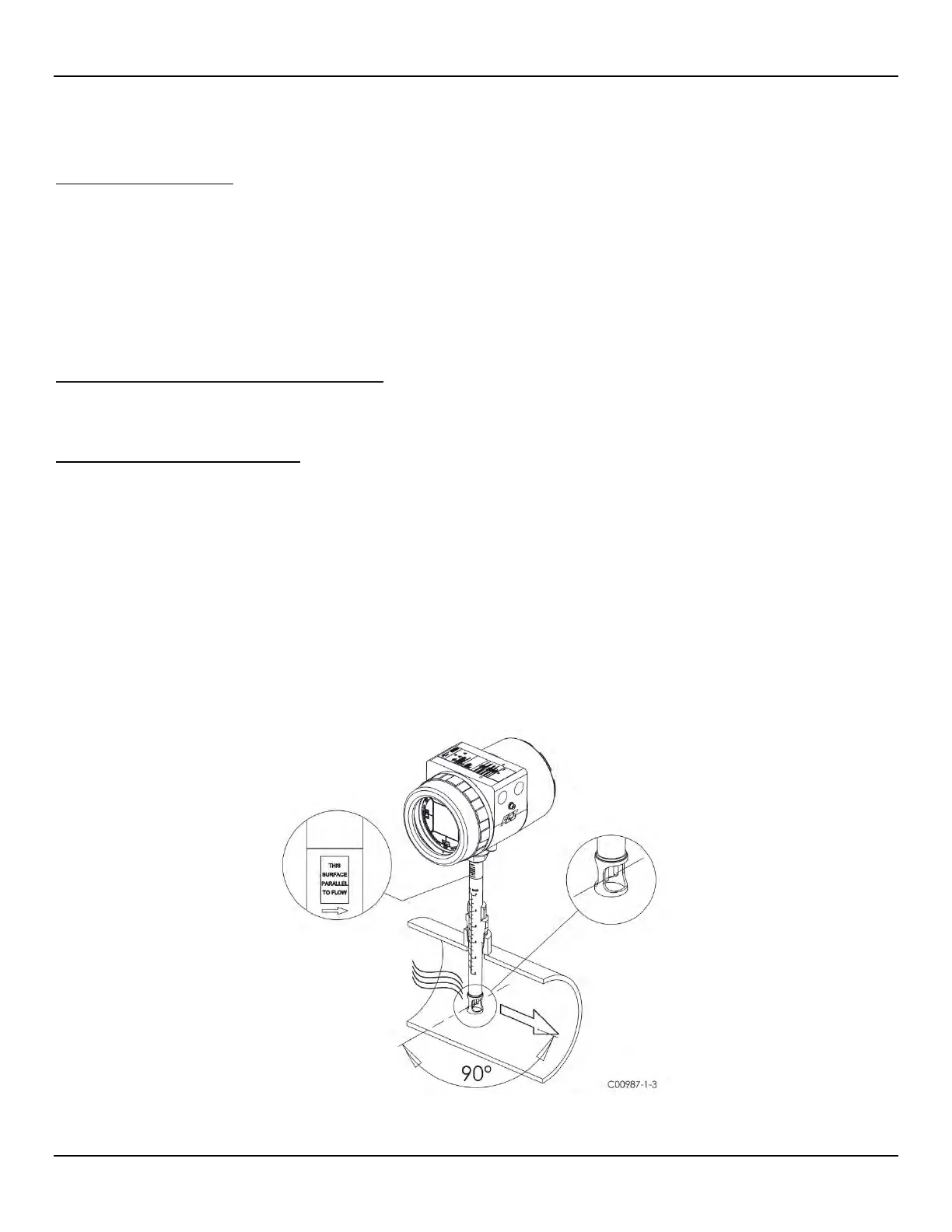

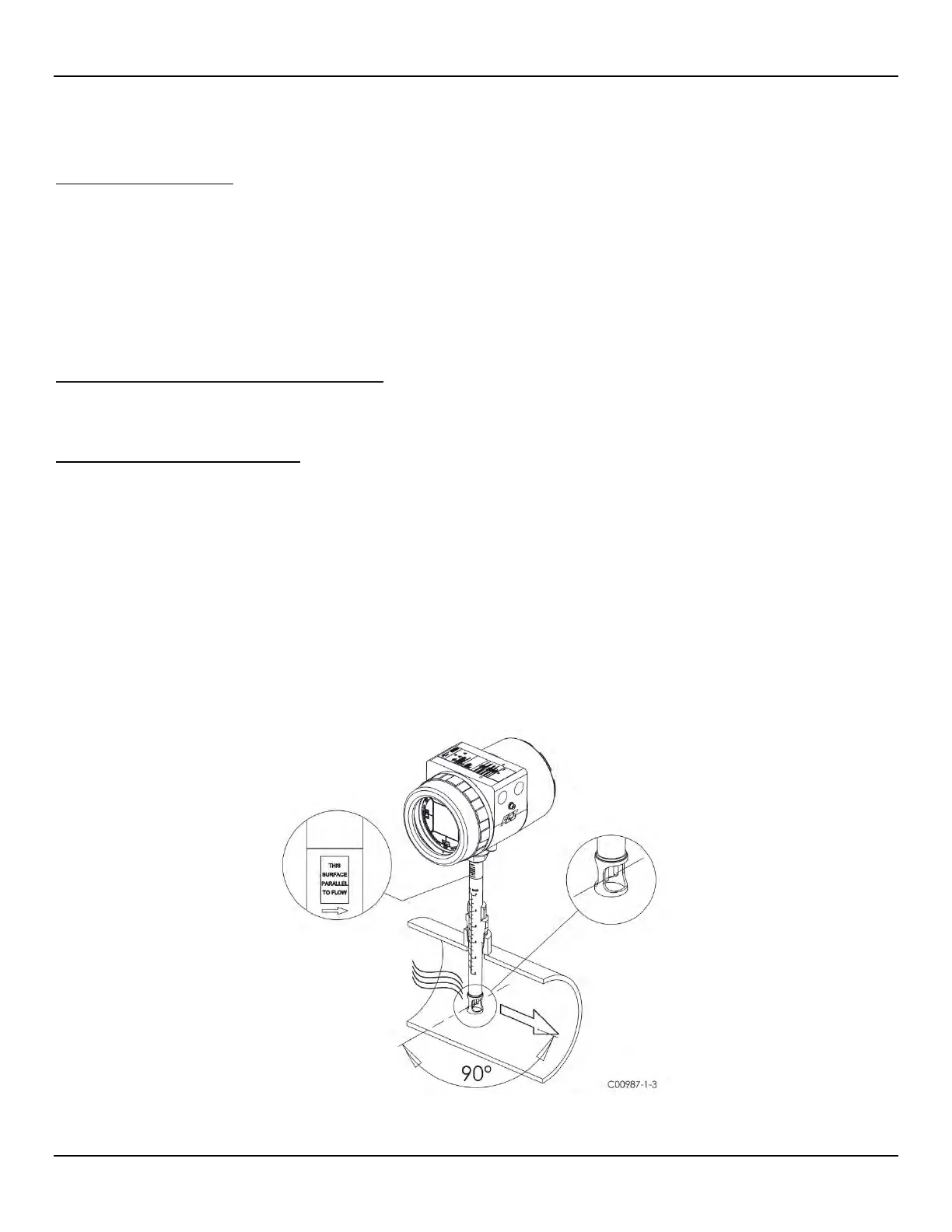

Mount the flow element to the process piping per the application piping requirements. Orient the instrument so that the flow arrow etched on the

element matches the direction of the process flow with the reference flat parallel to flow within ±3° of rotation. Insert a flow element with variable

insertion length ½” inch past the centerline of the process pipe or tube with the flow direction arrow correctly aligned and leveled. After the flow ele-

ment has been located correctly and tightened into place, verify that the process seal does not leak by slowly applying pressure until the maximum

operation pressure is applied. Check for leaks at the process connection boundary using standard leak detection methods.

Figure 1 below shows a properly mounted compression fitting process connection instrument.

Figure 1 – Example Compression Fitting Process Connection

Loading...

Loading...