INSTALLATION ST100A Series Flow Meter

22 Fluid Components International LLC

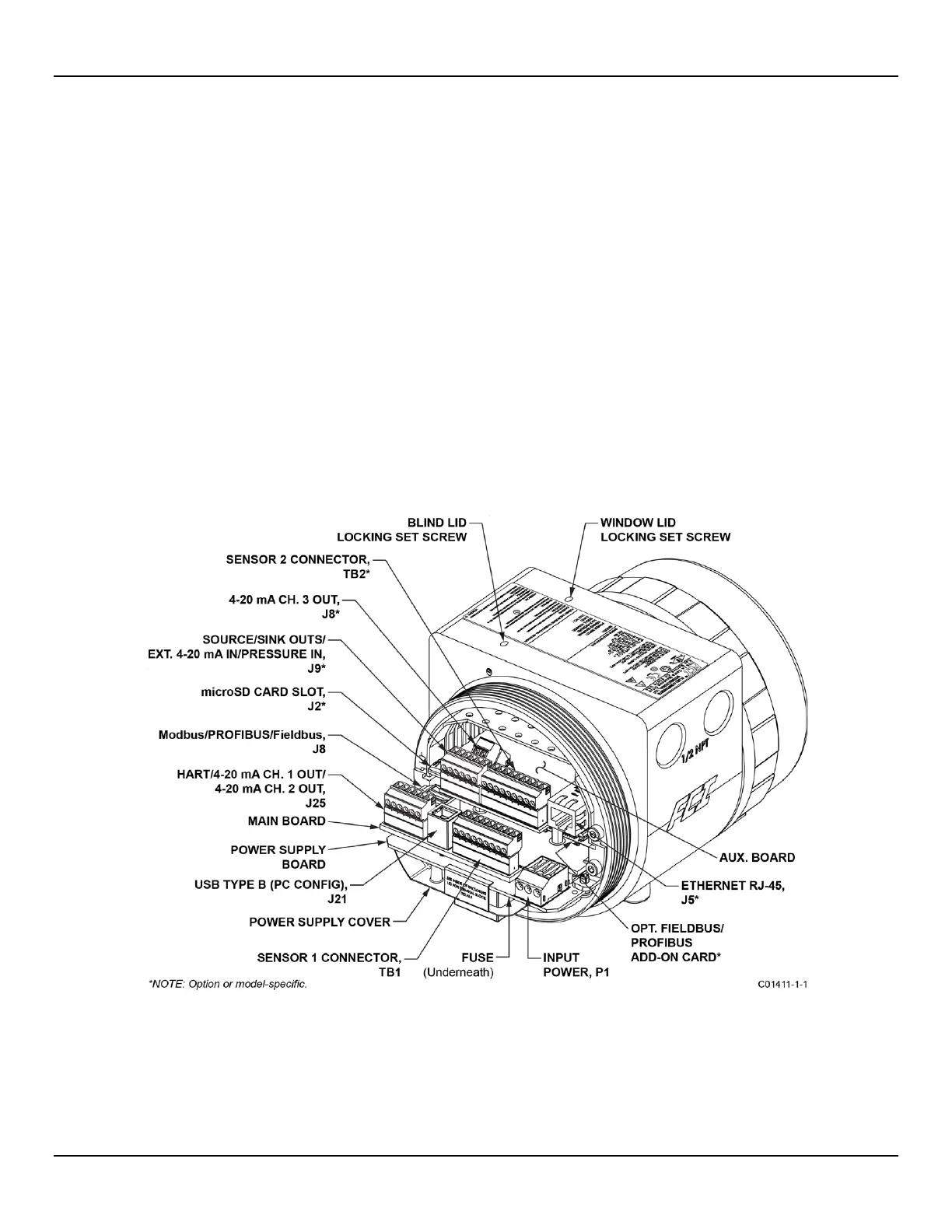

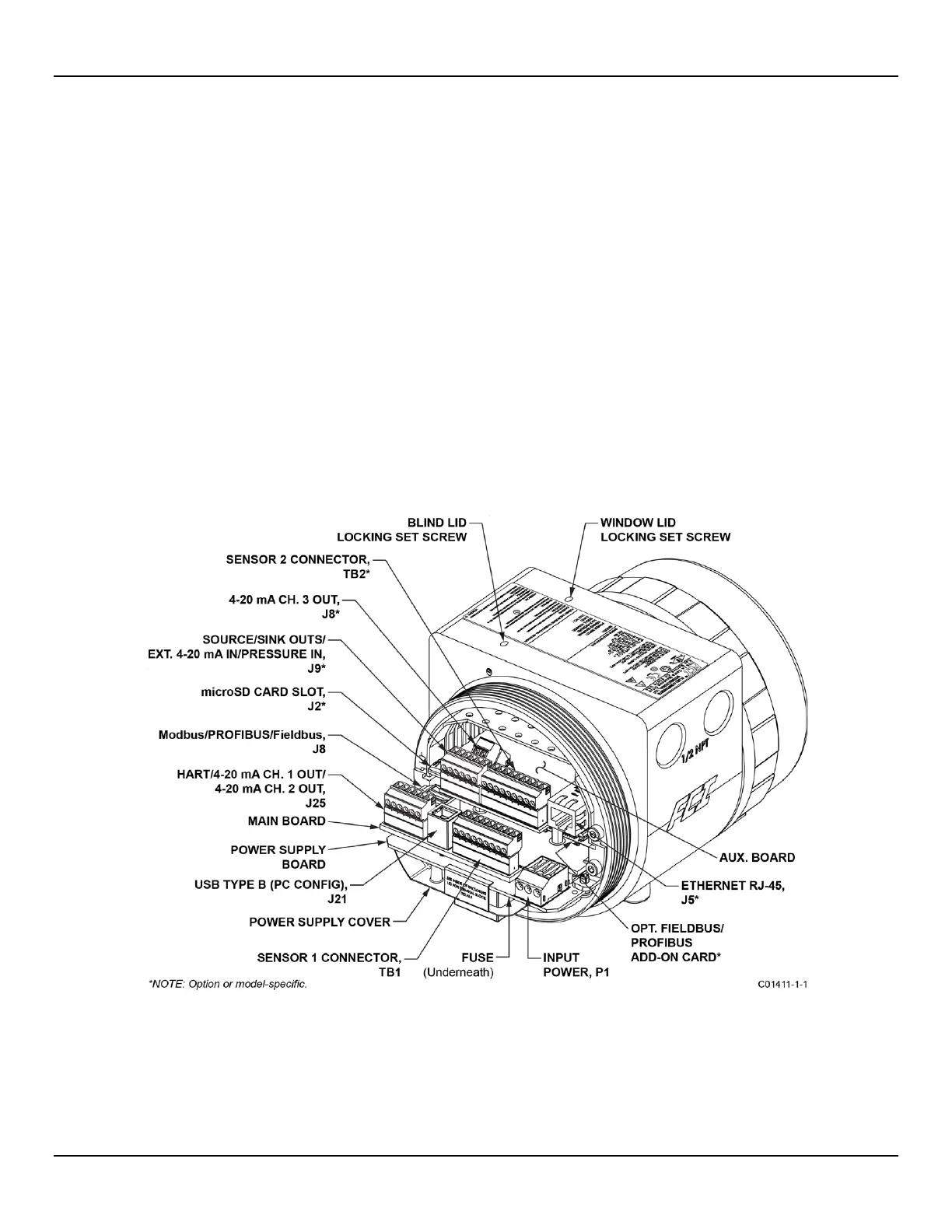

Accessing the I/O Connectors

Turn instrument power OFF before wiring the instrument.

Use caution inserting wires into electronics housing. The metal ends can damage circuit boards.

Remote Units: Avoid pulling, or inadvertently tugging, the remote cable when wiring the instrument. The sensor

connector/circuit board can be easily damaged by excess pulling of the remote cable.

Observe ESD precautions when wiring the instrument. Refer to ESD Precautions, page 16.

To access the instrument’s connection terminals first use a .050″ hex key to loosen the set screw locking the enclosure body blind lid. Then

unscrew the blind lid from the enclosure. Carefully pull the power and signal wires through the port to avoid damaging the electronics.

Figure 16 below shows the location of the ST100A Series I/O connectors as well as the lid set screw access holes in the enclosure body.

Note that some of the connectors shown are present only with certain options or model numbers (e.g., connector TB2 is present for dual

element models only).

Connect wiring as described in the following paragraphs. Reinstall the blind lid when done making the connections: Tighten the lid one full

turn past the point where the O-ring makes contact with the lid, and then tighten the lid set screw to lock the lid (set screw must not

protrude from its threaded hole after tightening).

Figure 16 – ST100A Series I/O Connector Locations

Loading...

Loading...