INSTALLATION ST100A Series Flow Meter

24 Fluid Components International LLC

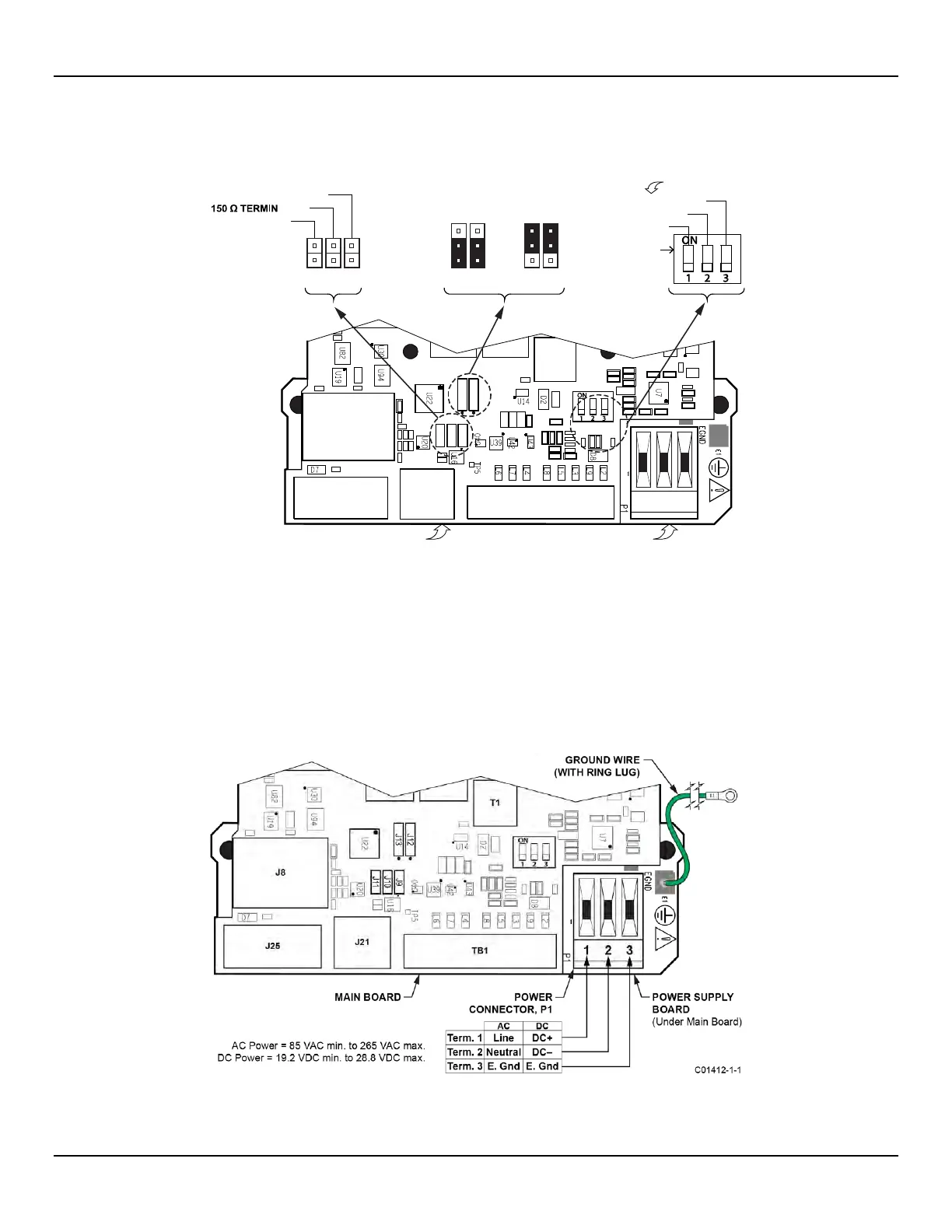

Configuration Jumpers/DIP Switch

When wiring the instrument for Modbus/Fieldbus/PROFIBUS make sure that the instrument is properly configured as shown in Figure 18

below. Refer to Modbus Connections on page 29 and Foundation Fieldbus/PROFIBUS Connections (Option) on page 30 for details.

Figure 18 – Bus Configuration 2 mm Jumper Headers and DIP Switch

C01419-1-1

J9

J12

J13

J10

J11

T1

J8

J25

J21

TB1

J11

J10

J9

J12

J13

J12

J13

MAIN BOARD

MODBUS FF/PROFIBUS

LINE PULLDOWN

LINE PULLUP

#SIM_ENABLE

#NV_ERASE

#HW_LOCK

ATION

POWER SUPP LY BOARD

(Under Main Board)

1

2

3

1

2

3

1

2

3

ON POSITION

ACTIVE WHEN ON

LINE CONFIG. BUS SELECT, J8 FF/PROFIBUSADD-ON CARD

DIAG/TEST

1

2

3

Input Power

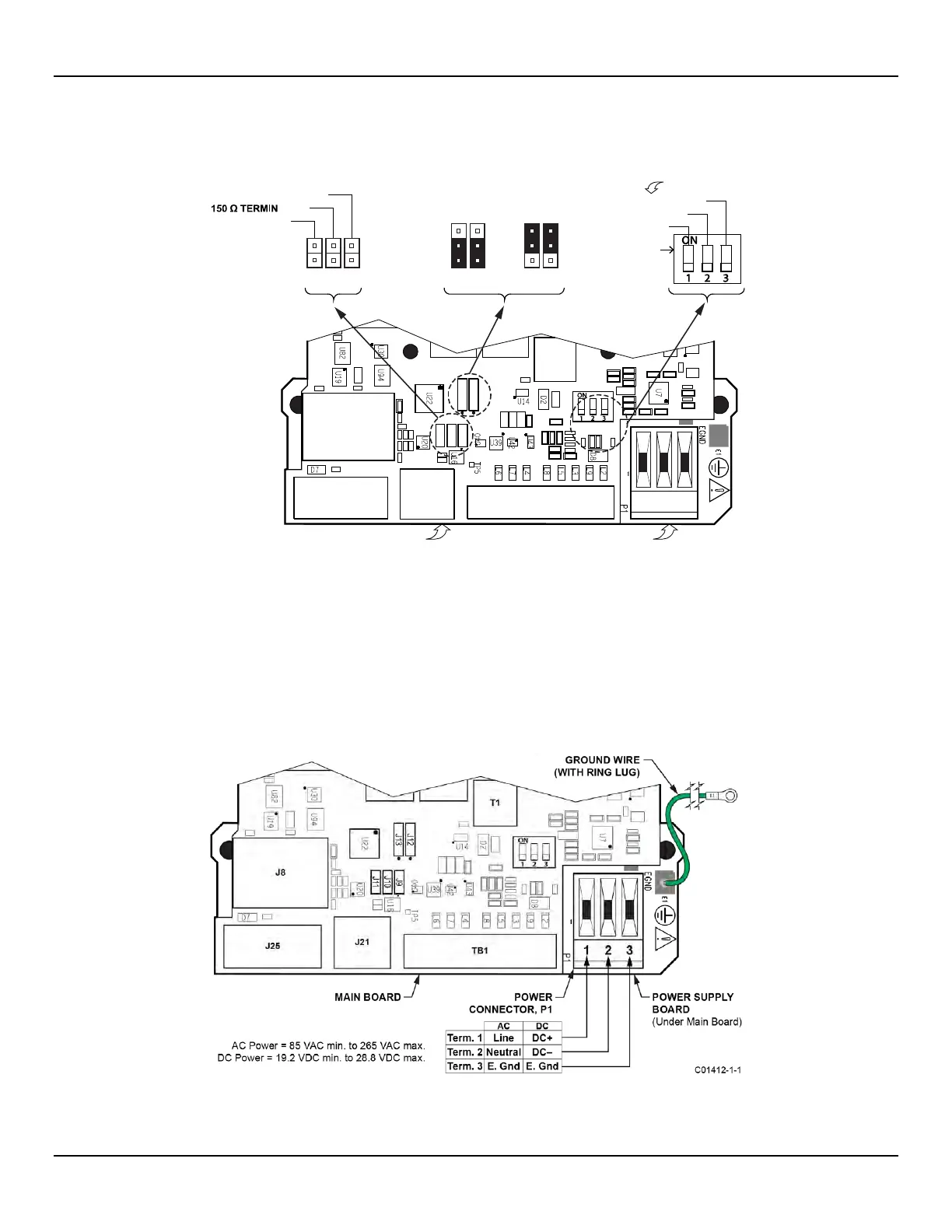

Install an AC line disconnect switch with fuse or breaker between the power source and the flow meter.

Always disconnect power before performing maintenance on wiring.

Connect input power to the 3-position Phoenix connector P1 on the power supply board as shown in Figure 19 below. The power

connector accepts 24–12 AWG (0.2 mm

2

– 1.5 mm

2

) wire (refer to Table 2, page 21 for wire size vs. length info). It is recommended that

wiring have a flammability rating of UL 2556 VW-1 or equivalent.

Figure 19 – Input Power Wiring

Loading...

Loading...