50 Chapter 4, Fine Tuning the Cutter

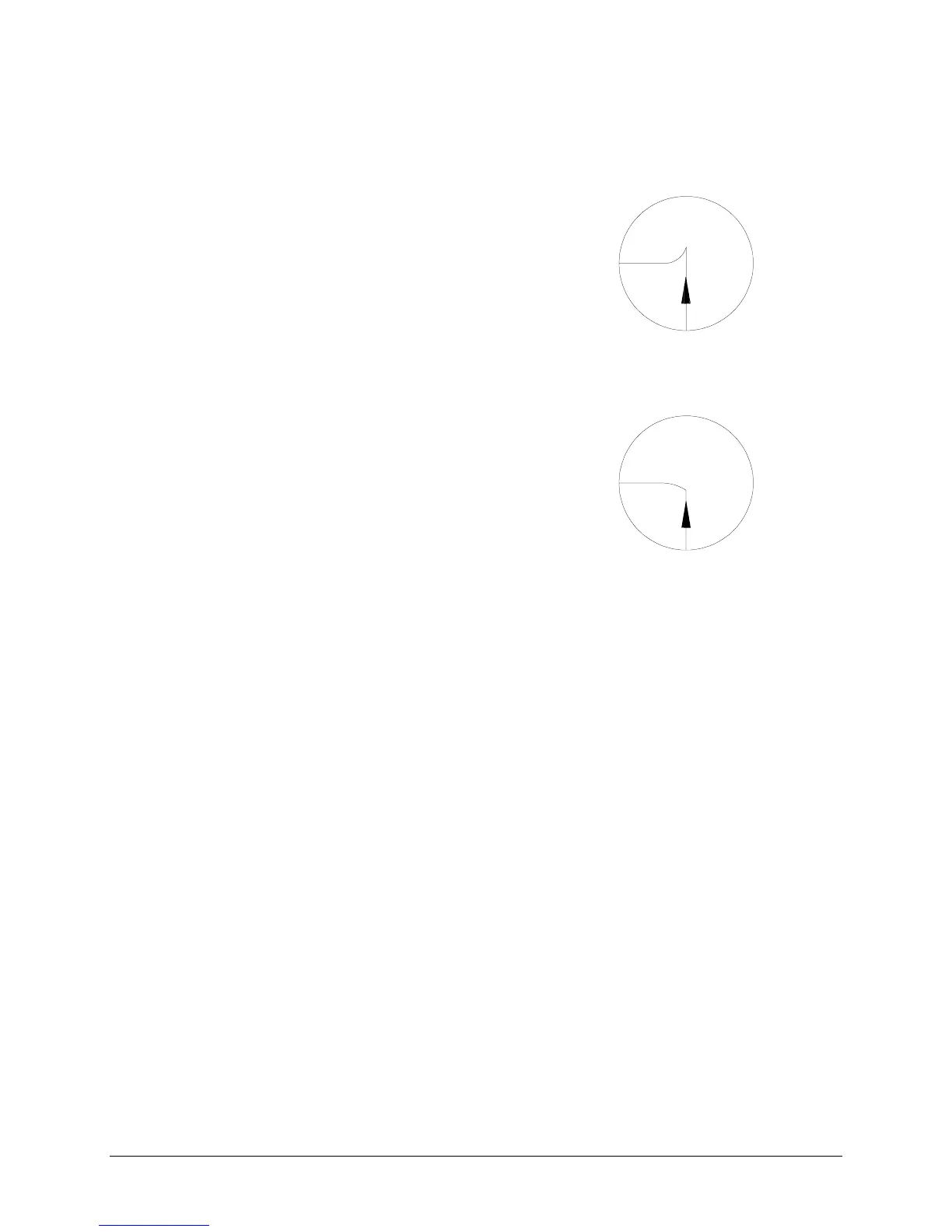

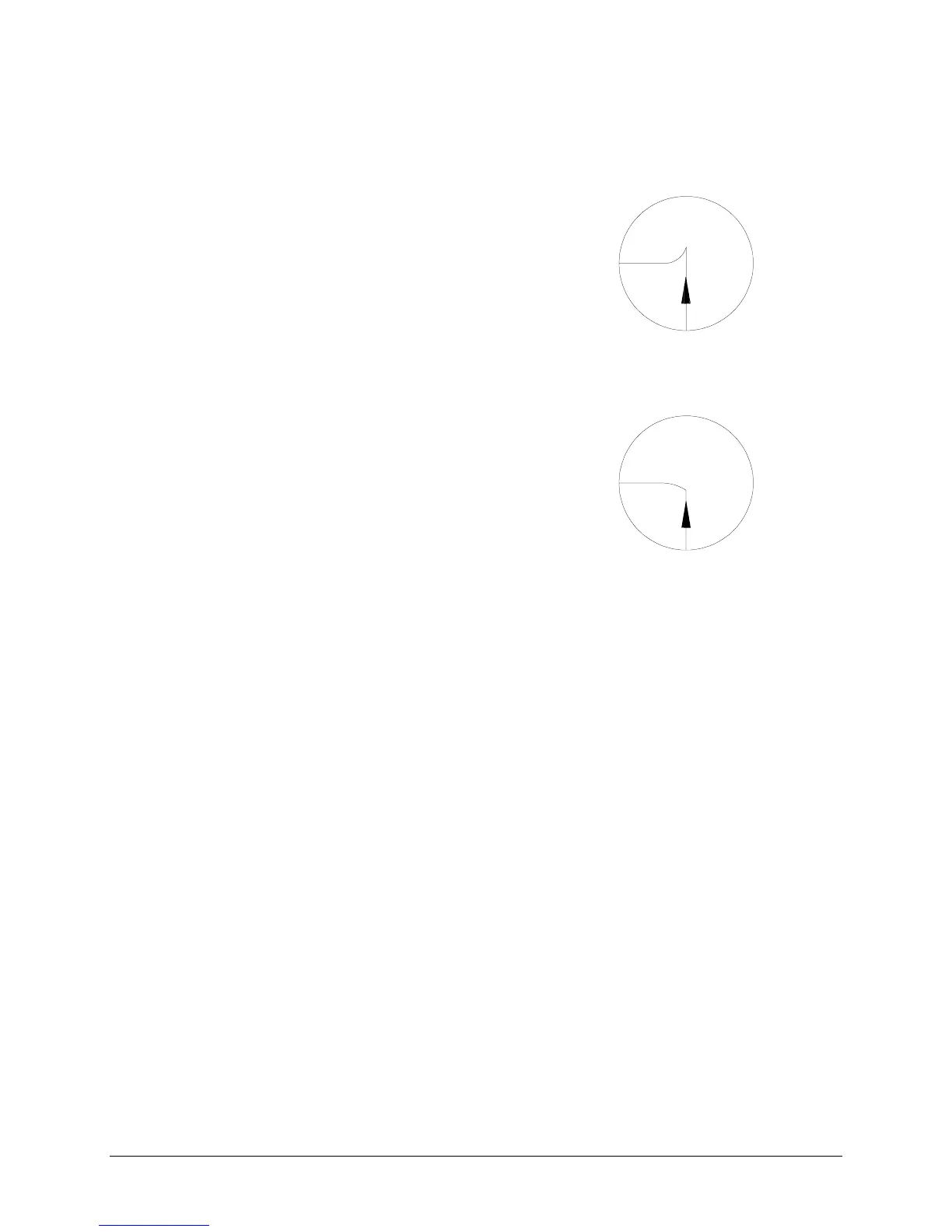

The diagrams below illustrate the results of incorrectly measured offsets.

Pointed corners: The offset is larger

than the actual knife offset.

In this case, a square corner will look like

the example to the right.

The cutting direction is indicated by the

arrow. The corners are not well formed

because the cutter cuts too far beyond the

corner.

Rounded corners: The Offset is smaller

than the actual knife offset.

In this case, a square corner will look like

the example to the right.

The cutting direction is indicated by the

arrow. The corners are not well formed

because the cutter did not cut far enough

before turning the corner.

ADJUSTING THE OFFSET

To obtain good quality, you should perform this routine each time you

change cutting blades or switch to another type of material.

1. Make sure the cutter is switched on.

2. Load a sheet of material about 10" (25 cm) wide.

3. Select a tool that is defined as a KNIFE (factory default: TOOL 1 is

Knife 1, TOOL 2 is Knife 2).

If you select a TOOL that is defined as a PEN (factory default: TOOL 3

is Pen 1, TOOL 4 is Pen 2), the cutter will not react, as this function is

only active for knife settings.

4. Switch the cutter

offline

by pressing the ONLINE key. The ONLINE

LED indicator should then go off.

5. Press the ENTER and OFFSET (

➢

) keys simultaneously. This will put

the cutter into the OFFSET test mode.

Loading...

Loading...