6 - Maintenance

168

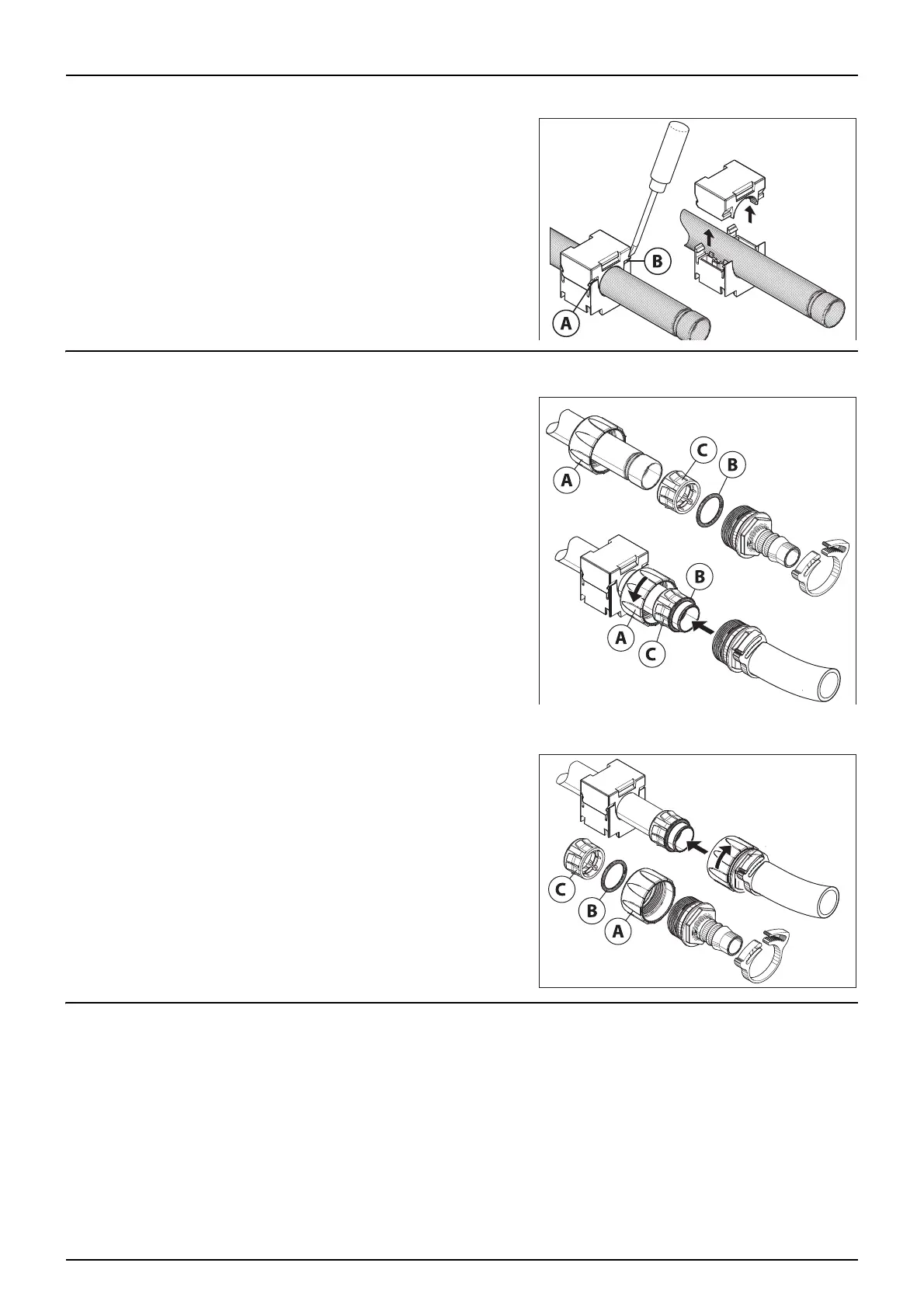

Feed Pipe Clamp Assembly

A feed pipe can be removed from the pipe clamps the following way:

1. Use a flat bladed screwdriver to prize the cover off the first corner

(A).

2. Hold the clamp top with your hand and prize off the opposite

corner (B) with the screwdriver.

3. Prize off the other side of the pipe clamp with the screwdriver.

Take out the feed pipe.

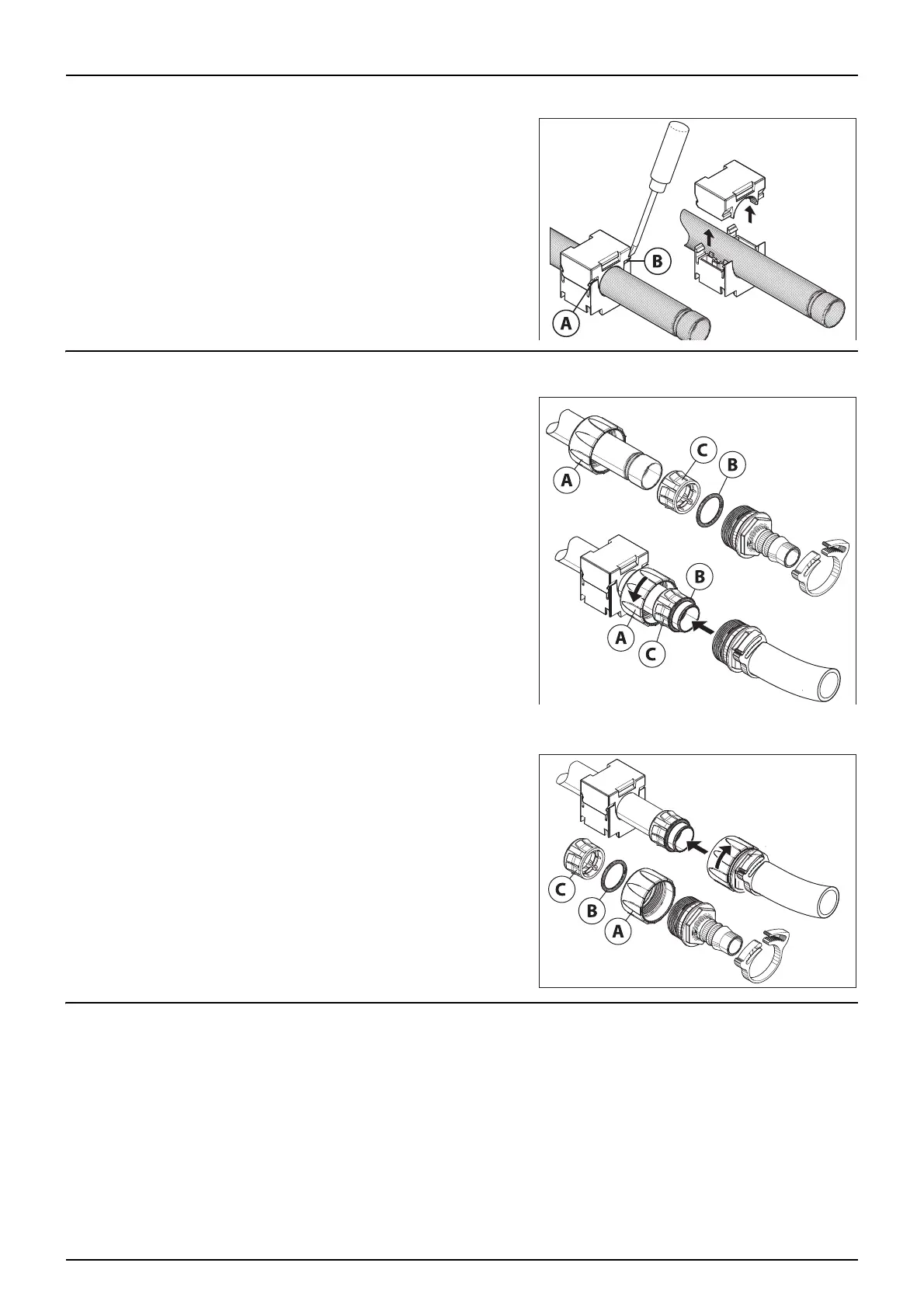

Feed Pipe Snap-Lock Assembly

Disassembly

1. Unscrew the union nut (A) completely.

2. Pull the feed piping and hose barb apart.

3. Take out the O-ring (B).

4. Inspect and oil O-ring (B). Change the O-ring (B) if worn, before

reassembly.

Reassembly

1. Check that the barbed lock ring (C) is fitted to the feed pipe with

barb pointing away from pipe opening.

2. Fit the oiled O-ring (B) on top of the lock ring (C).

3. Push the feed pipe and hose barb together.

4. Screw the union nut (A) on the hose barb and tighten union nut

(A) by hand.

Initial Assembly of Fittings

μ

ATTENTION! This method can only be used for pipes not fitted

into pipe clamps.

1. Fit the barbed lock ring (C) to the feed pipe with barb pointing

away from pipe opening.

2. Fit the oiled O-ring (B) on top of the lock ring.

3. Screw the union nut (A) on the hose barb.

4. Press the feed pipe and hose barb together.

5. Tighten the union nut (A) by hand if needed.

Nozzle Holder Assembly

If leaks of fluid occur in the nozzle holders on the spray boom, it is necessary to check the gaskets. The nozzle holder need

to be disassembled to locate the gaskets. Occasional maintenance of the gaskets and nozzle holders is recommended.

Poor sealing are usually caused by:

• Missing O-rings

• Damaged or incorrectly seated O-rings

• Dry or deformed O-rings

• Foreign objects.

Loading...

Loading...