141

6 - Maintenance

Lubrication

General information

Always store lubricants in a clean, dry and cool place - preferably at a constant temperature. Keep the containers and

funnels.

Clean lubrication points before applying the lubricants.

Always follow the recommendations concerning quantity. If no recommended quantity is given, feed lubricator until new

grease becomes visible.

Suitable Lubricants

÷

ATTENTION! values are given are for information. Only level indicated by the gauge should be taken into

consideration

Maintenance intervals

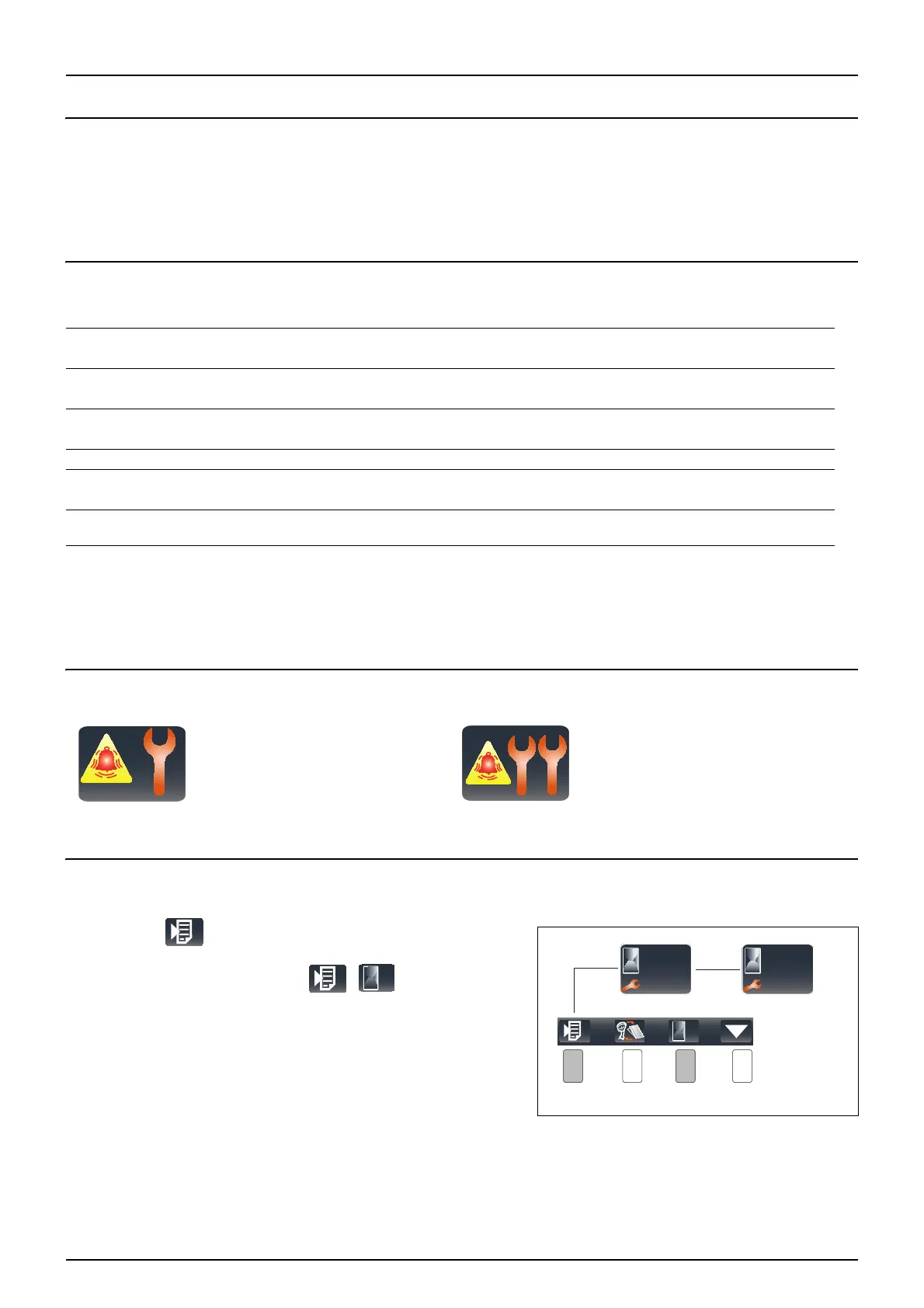

Resetting the maintenance intervals

• Press on button and navigate to display the hour meter

reading

• Simultaneously press for 5 sec. buttons for

resetting.

The screen indicates the nest period of maintenance

Components Quantity Recommended lubricants - TOTAL Type

DEUTZ TCD 6.1L6 engine

crank case + filter

15.5 litre TRACTAGRI HDZ FE 10W30

DEUTZ - DQC- III- LA

A

Hydraulic Transmission 50 litre EQUIVIS ZS46

AFNOR NF E 48-603HV ISO 6743/4HV

B

General greasing Multis EP2

ISO-L-XBCFB 2

C

Spraying pump 464-10 or 464-12 35 gram TOTAL COMPLEX SHD 460 D

Coolant 20 litre COOLELF AUTO SUPRA -37°C

COOLELF AUTO SUPRA -37°C AFNOR NFR 15-601 - BS 6580

E

Pneumatic lubricator Mineral Oil

ISO VG22 viscosity 22 mm²/s à 40°c

F

Air Compressor 40 millimeter Synthetic Oil - SAE30 G

First maintenance at 150 hours

Regular maintenance every 500 hours

1600 hrs

hrs

0

945

hrs

1600 hrs

945 hrs

400 hrs

0

hrs

0

hrs

Loading...

Loading...