128 HC900 Process & Safety Controller User and Installation Manual Revision 6

21 April 2017

Set IP addresses and

subnet masks.

C30/C50: 192.168.1.254 and Subnet Mask of 255.255.255.0.

C70/C75: E1: 192.168.1.254, E2: 192.168.2.254. Must be on

different subnets.

Links to controller communication ports

Refer to Table 17 and the figure in Step 2 above. Port availability depends on Controller model.

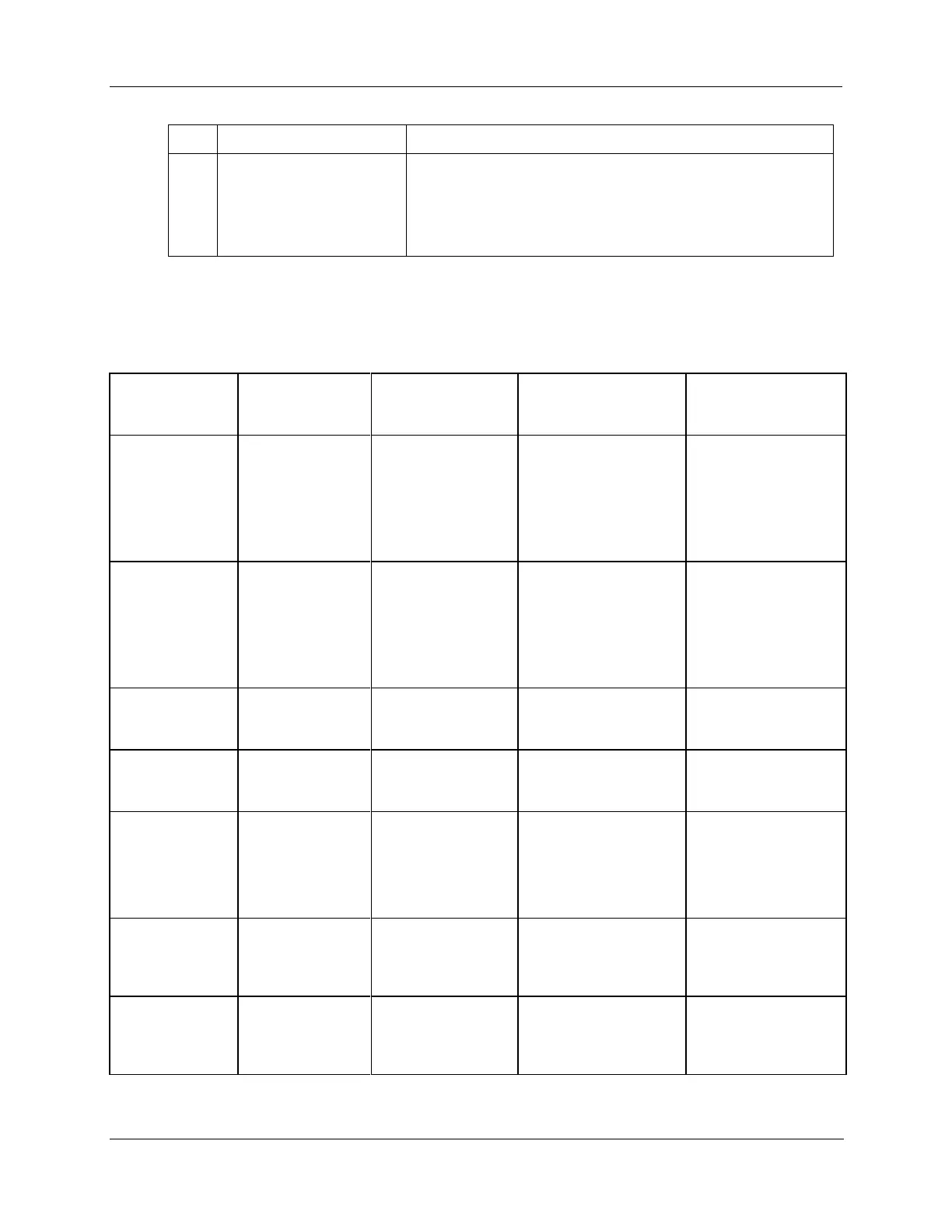

Table 17 – Links to Controller Communication Ports

Controller

Port

/Connector Type

Legacy controller

only RS-232

3-plug connector

RS-232 Null Modem

cable, up to 50’

Or

RS-232 PC modem

cable, up to 50’

Serial port of PC (w/ Null

Modem cable)

or

Modem. Refer to RS-

232 Remote Connection

to PC Configuration Tool

on page 135.

For Wiring details of

Null Modem cable see

Table 19.

Legacy controller

only RS-232

3-plug connector

Modbus master

(controller is single

slave)

RS-232 Null Modem

cable, up to 50’

Or

RS-232 PC modem

cable, up to 50’

RS-232 to RS-485

converter

Refer to device’s port

instructions

Legacy controller

only RS-232

3-plug connector

Modbus master

(controller is one of

multiple slaves)

RS-232 to RS-485

converter

Refer to device’s port

instructions

Legacy controller

only RS-232

3-plug connector

Modbus slave

network (controller

is master)

RS-232 to RS-485

converter

Refer to device’s port

instructions

Belden #9271 (or

equivalent)

Terminal connector of

operator interface. (Refer

to Table 18.)

Connect from each CPU

(A and B) to the OI.

SIL applications require

shield drain wire to be

connected to grounding

bar.

Modbus master

(controller is slave)

Belden #9271 (or

equivalent)

Refer to device’s port

instructions

SIL applications require

shield drain wire to be

connected to grounding

bar.

Modbus slave

network (controller

is master)

Belden #9271 (or

equivalent)

Refer to device’s port

instructions

SIL applications require

shield drain wire to be

connected to grounding

bar.

Loading...

Loading...