188 HC900 Process & Safety Controller User and Installation Manual Revision 6

21 April 2017

I/O Module Diagnostic Indication

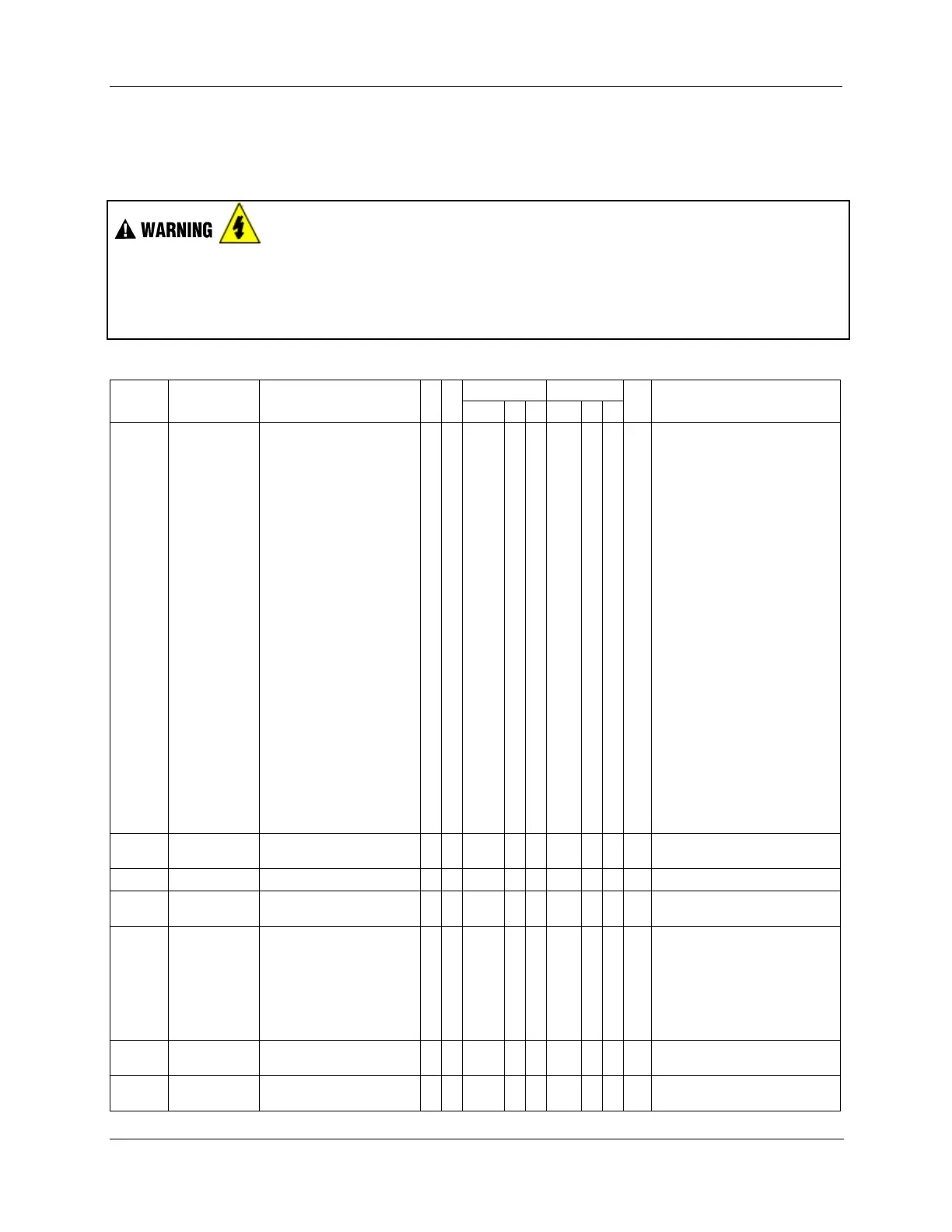

To indicate the type of diagnostic failure, the module’s status LED is flashed red with a number of quick

strobes followed by a long off time. Table 31 outlines the potential module diagnostics.

Hazardous voltages exist at terminal blocks.

AO8 and AO16 modules require at least one channel to be configured prior to a cold start for the module

to work properly. Subsequent channels then may be added with a hot start.

Failure to comply with these instructions could result in death or serious injury.

Table 31 – I/O Module LED Diagnostics

The module is in the failsafe state

because it is not receiving message

requests from the CPU or Scanner

at a rate that satisfies the configured

failsafe timeout.

1. If expansion I/O rack, go to step 2.

If no expansion I/O rack, go to

step 3.

2. Check the Scanner status LED

(see p. 183).

If it’s flashing 6 times, proceed

with step 3.

If it’s flashing some other red

status code, refer to Table 29

to solve that problem first.

If it’s flashing green, the module

probably is not required in the

configuration.

If it’s not on or steady, cycle

power to the scanner.

3. Make sure the module is the

correct one for the configuration.

4. Remove the module and check

for a bent pin, then reinsert the

module

5. Replace the module

6. Remove other modules and

replace one at a time until the

problem reoccurs. Most likely the

last module inserted needs to be

replaced.

7. Replace the rack.

EA ROM Failed its checksum

1. Remove/reinsert module.

1. Remove/reinsert module.

1. Remove the module and check

for a bent pin, then reinsert the

module

2. Measure power supply voltage. If

not correct, replace power supply.

3. Replace module

4. Replace rack

CRC failure of primary and backup

factory calibration

CRC failure of field calibration

values

1. Remove/reinsert module.

Loading...

Loading...