Revision 6 HC900 Process & Safety Controller User and Installation Manual 81

21 April 2017

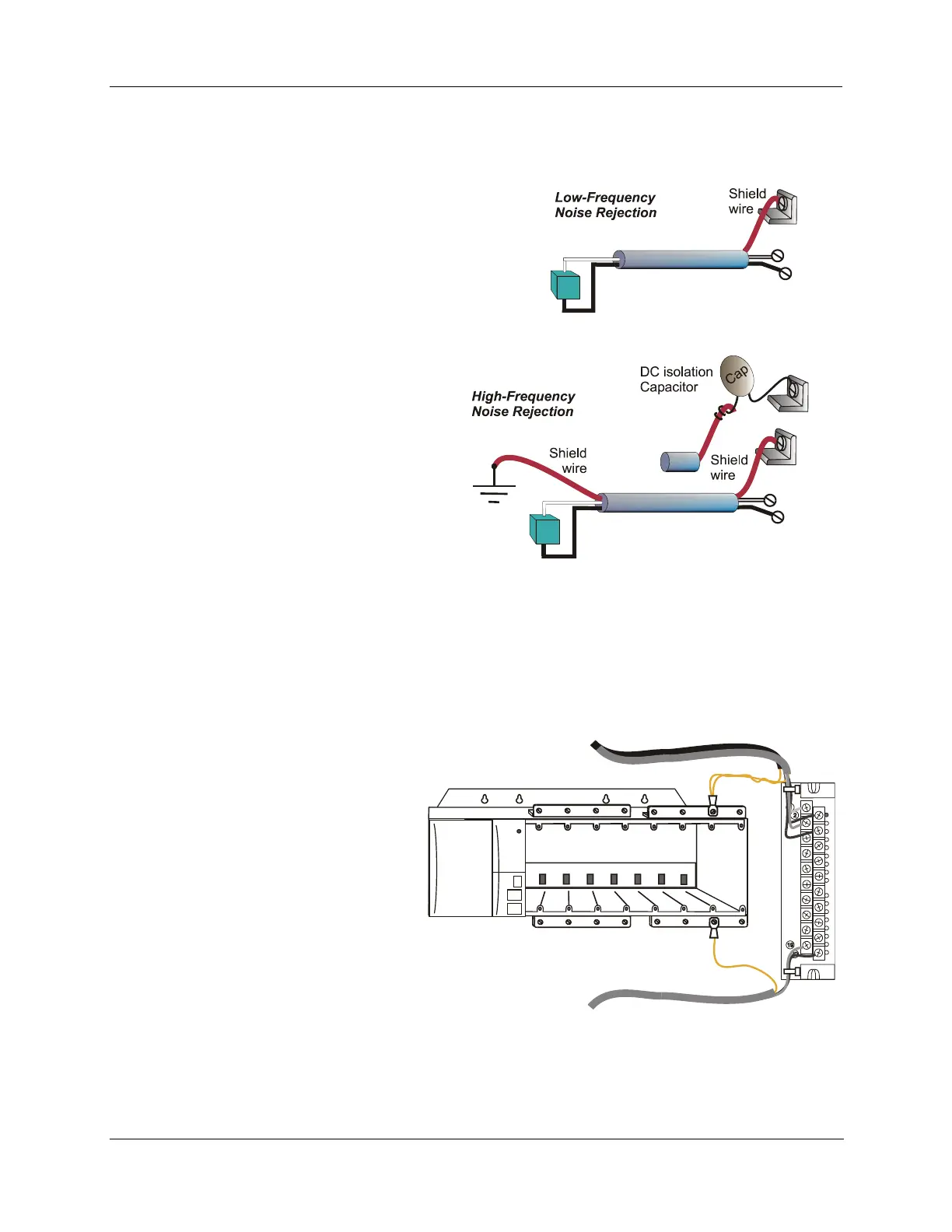

Signal Grounding (

Figure 39)

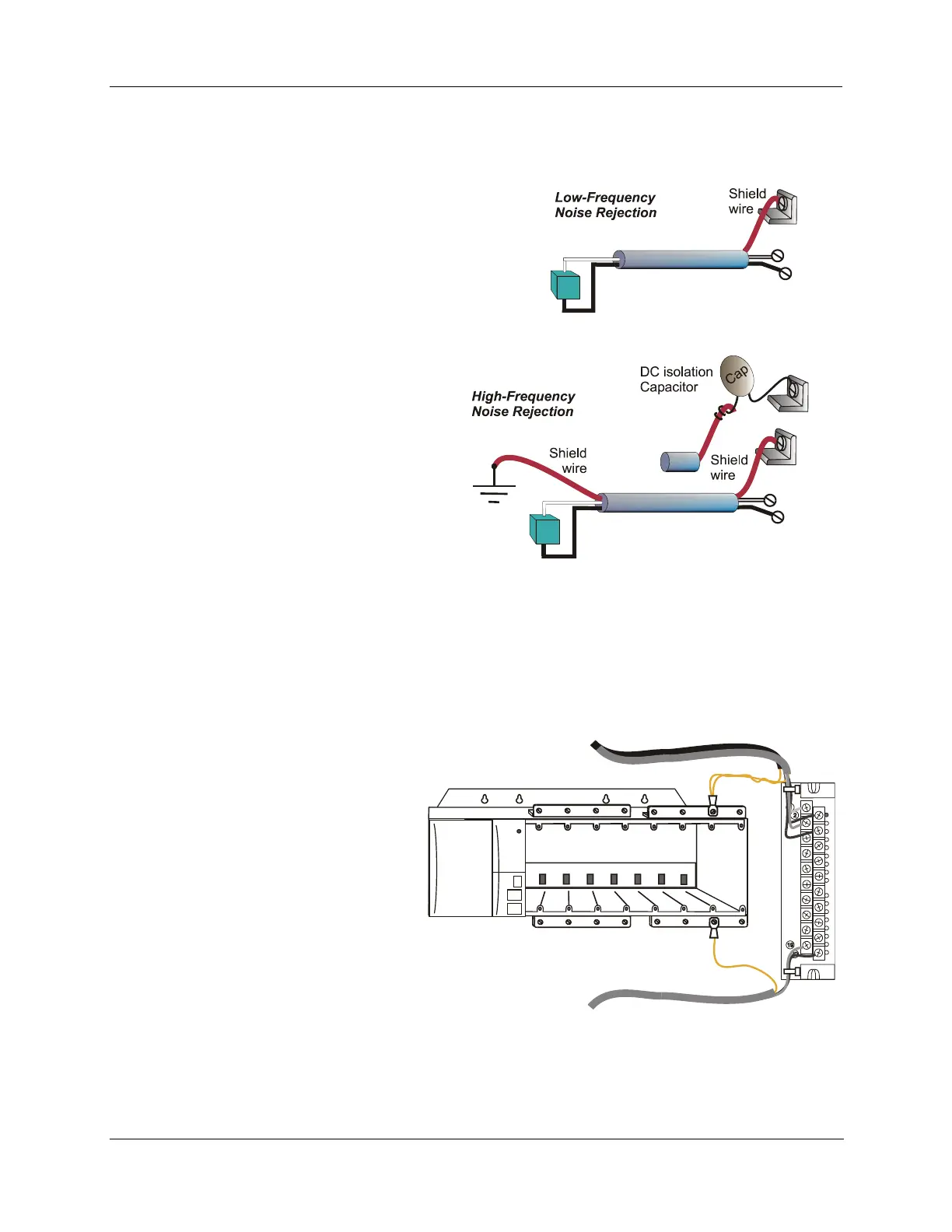

The shield for each input should be grounded

at the grounding bar (optional) at the top or

bottom of each rack as indicated in Figure 40.

For low-frequency noise rejection, I/O wiring

shields should be grounded only at the

controller end.

For high-frequency noise rejection, shields

should be grounded at the controller and at

the field device. If the ground voltage

potential at the field device is different from

that at the controller, a DC isolation capacitor

should be used between the shield and the

grounding bar on the rack.

Figure 39 – Signal-Wire Grounding

Aluminum grounding bars for I/O wiring are available as options. When selected for use, they are fastened

to the top and/or bottom of each rack, as indicated in Figure 40. To enable connection of multiple ground

wires with a single screw, the wires can be twisted together and secured with a wire lug.

To facilitate module replacement, it is advisable in most cases to route all wiring through either the top or

the bottom of the terminal block. This

allows the terminal block to pivot up or

down, allowing ready access to the

module, and is the preferred method

for a limited number of wires.

For a larger number of wires, or for

wires of a heavier gauge, it is advisable

to route some wires through the top of

the terminal block, and some through

the bottom, as indicated in Figure 40.

In this case, it is necessary to adjust

wire length so as to ensure adequate

flexibility of the twisted wires and to

provide clearance sufficient to remove

the I/O module.

Figure 40 – Wire-Shield Grounding

Loading...

Loading...