Revision 6 HC900 Process & Safety Controller User and Installation Manual 177

21 April 2017

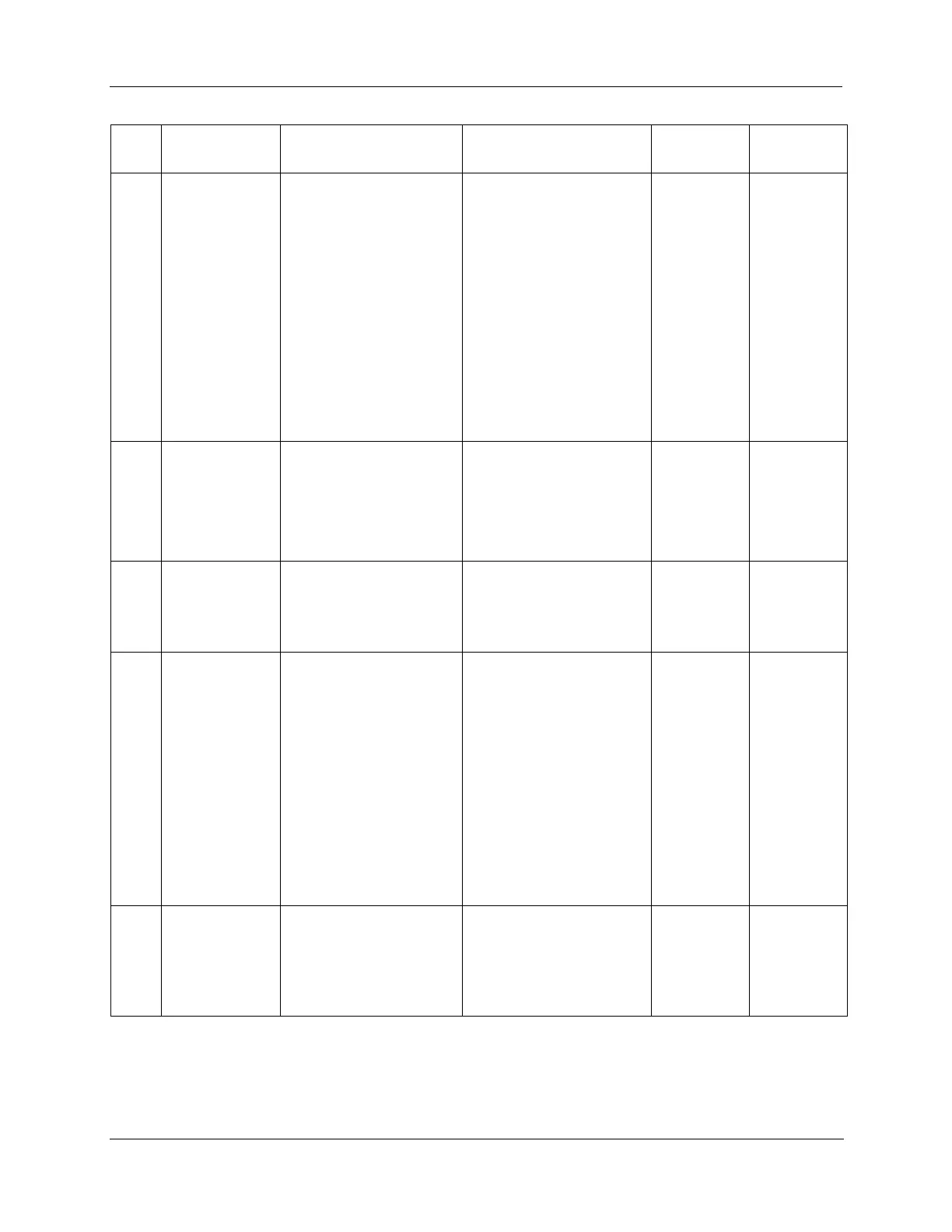

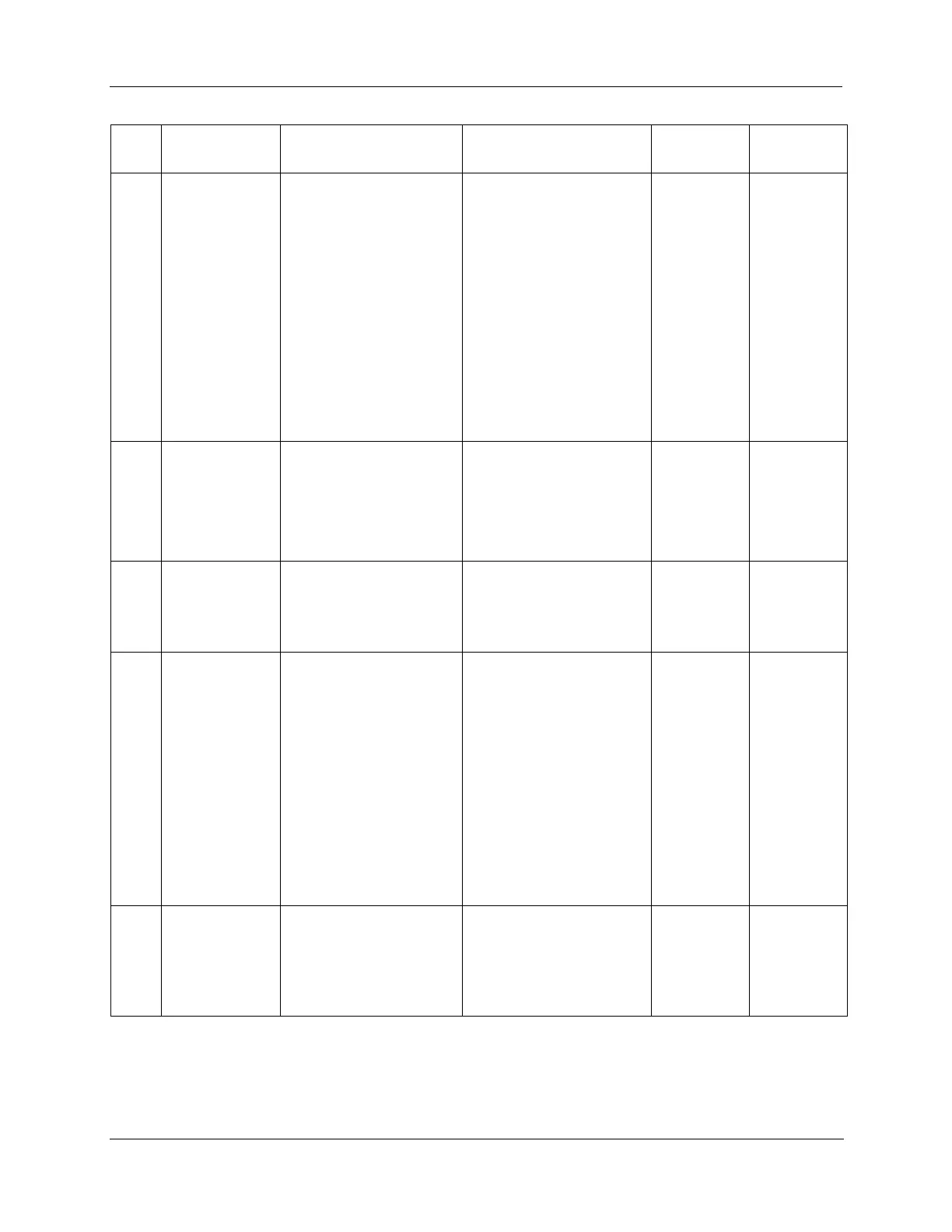

Lead and/or Reserve Controller

Action(s)

HCDesigner/HC

Utilities Indication

There are slave blocks

in the configuration,

and no communication

port is configured as a

Modbus master.

MSTRFAIL pins on ASYS and

FSYS blocks turn on.

All Modbus slave and Modbus

read blocks freeze their output

pins to the last value.

All slave blocks have their BAD

COMM pin on.

All slave blocks have their NO

SCAN pin on.

IN SCAN STATUS is set to NO

for all slaves.

COMM STATUS is set to BAD

for all slaves in the function block

diagram.

Statistical counters for all slaves

are 0.

1. Use the OI, HCDesigner, or

HCUtilities to configure one of the

serial ports (S1 or S2) as a master.

2. Use the OI, HCDesigner, or

HCUtilities to download a

configuration that has no slave

blocks.

Controller mode is

changed to RUN-

Locked while there are

forces present on

safety worksheet.

Controller will not go to RUN-

Locked mode.

1. Change mode back to RUN

mode OR

2. Clear all safety forces using HCD

through Monitor->Forced

Blocks OR

3. Force a cold-start

In HCD, "System

Diagnostics"

shows status as

"Invalid Change of

Mode"

Controller mode is

changed to RUN-

Locked when safety

configuration is

changed at run-time.

Controller will not go to RUN-

Locked mode.

7. To clear the diagnostic:

8. 1. Change mode back to RUN

mode OR

2. Force a cold-start

In HCD, "System

Diagnostics"

shows status as

"Safety

Configuration mis

match"

One of the following

microprocessor

exceptions occurred:

Watchdog timer

timeout

Address error

Prefetch error

Data abort error

Software interrupt

Undefined

instruction error

At the time of the exception, the

microprocessor resets. If it’s the

Lead controller, and there is an

available reserve, a failover occurs.

When the microprocessor

completes its reset condition, it will

become an available reserve if a

lead is present or become a lead if

no lead is present.

This diagnostic will cause the

HWOK pins of the AYSY and FSYS

blocks to be turned off.

To clear the diagnostic, force a cold

start.

If the problem reoccurs, try the

following:

1. Ensure the system is properly

grounded

2. Ensure the system is properly

isolated from external noise sources

3. Upgrade the firmware

4. Replace the CPU board.

5. Contact Honeywell Personnel.

If the lead’s status

LED is indicating

the failure, see

CPU in the “Lead

CPU Diagnostics”

display.

If the reserve’s

status LED is

indicating the

failure, see CPU in

the “Reserve CPU

Diagnostics”

display.

If the lead’s status

LED is indicating

the failure, see

CPU Diagnostics

in the “Lead

Diagnostics

Overview” dialog

box.

If the reserve’s

status LED is

indicating the

failure, see CPU

Diagnostics in

the “Reserve

Diagnostics

Overview” dialog

box.

One of the exception

vectors located in RAM

became corrupted.

The exception vector was

automatically corrected in the

controller’s RAM and the controller

continues to operate normally.

This diagnostic will cause the

HWOK pins of the AYSY and FSYS

blocks to be turned off.

Loading...

Loading...