you can raise the torch to increase the clearance.

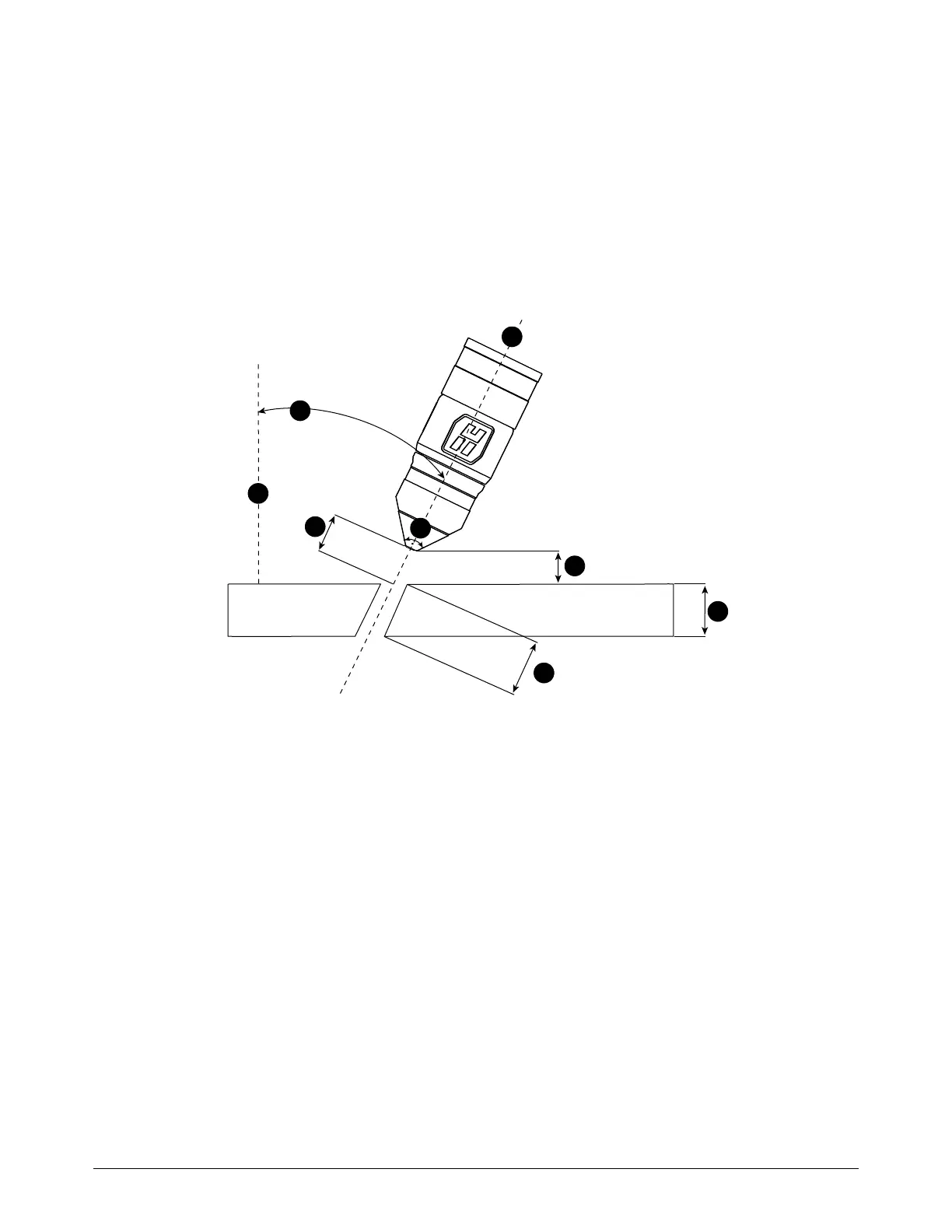

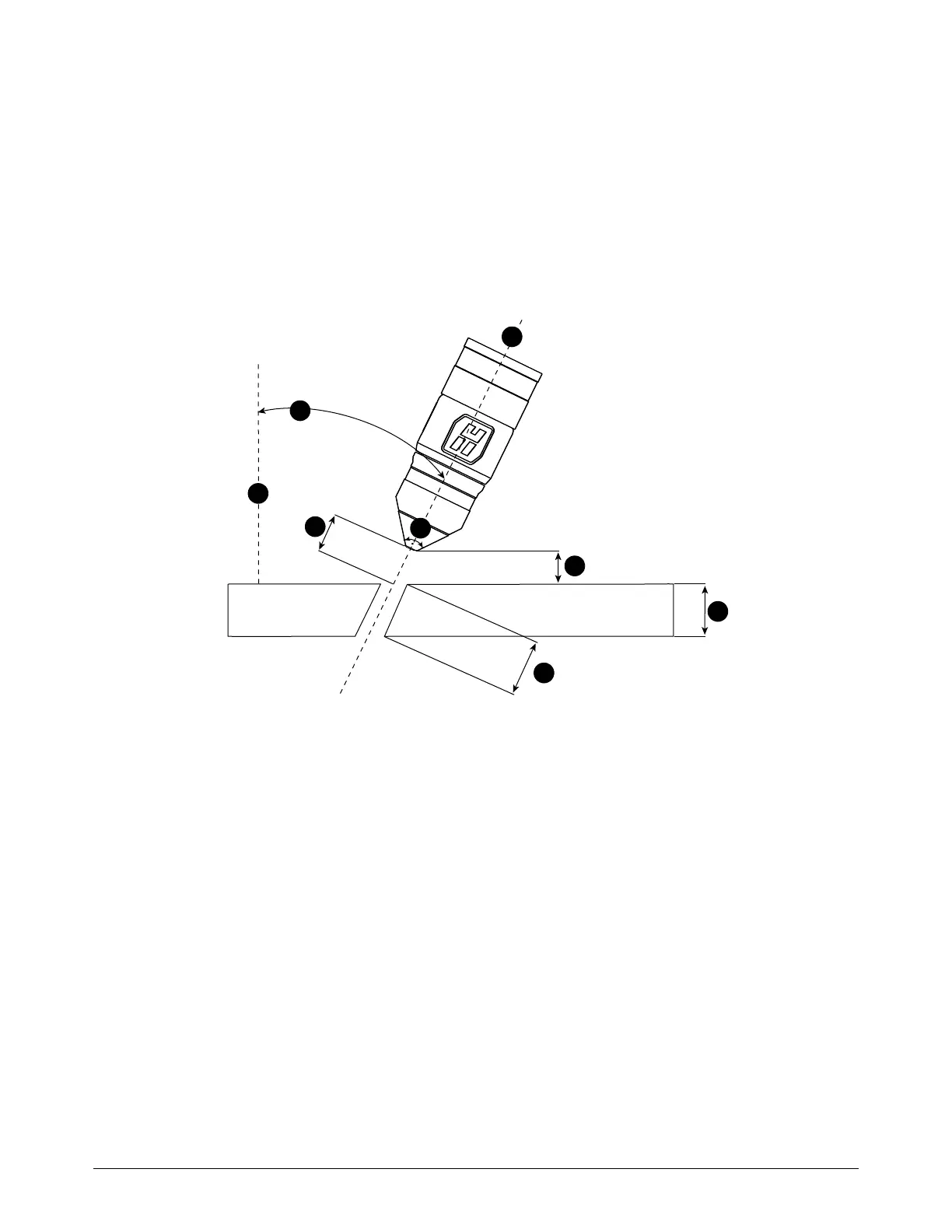

1 Perpendicular line: The imaginary line that is

perpendicular (at a 90° angle) to the workpiece.

2Bevel angle: The angle between the center line of

the torch and an imaginary line that is

perpendicular to the workpiece.

3 Cut height: The linear distance from the center of

the torch to the workpiece surface along the torch

center-line. For optimal results, select a cut height

that is based on an “effective thickness” value in

the cut charts.

If a specific cut height is inconsistent with a

clearance requirement, select a slightly higher cut

height to prevent torch collisions.

4 Cone angle: All XPR torches have a 76° cone

angle that makes it possible to tilt or position the

torch up to 52°. If you need an angle greater than

52°, you can raise the torch to increase the

clearance.

5 Torch center line: The imaginary line along the

central axis of the torch.

6 Clearance: The vertical distance from the lowest

point of the torch to the surface of the workpiece.

Make sure that the distance is at least

2 mm – 3 mm (0.080 in. – 0.120 in.) to minimize

torch contact with any slag on top of the plate.

7 Nominal thickness: The vertical thickness of a

workpiece. This is the thickness of the metal that

the plasma arc cuts, marks, or pierces.

8 Effective thickness: The distance that the plasma

arc travels through the metal while cutting. This

value is equal to the nominal thickness, divided by

the cosine of the bevel angle.

Loading...

Loading...