Connect for Communication

148 809480 Instruction Manual XPR300

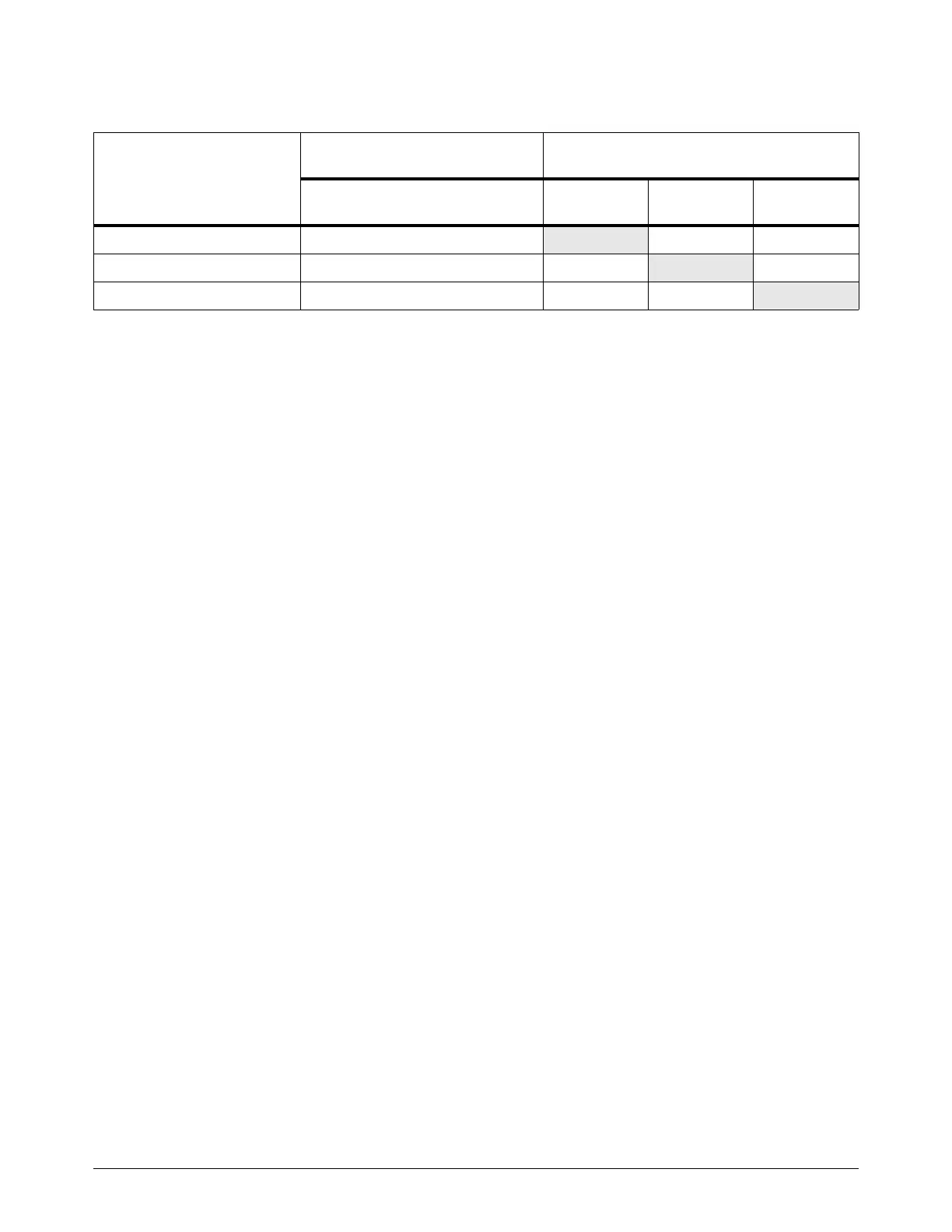

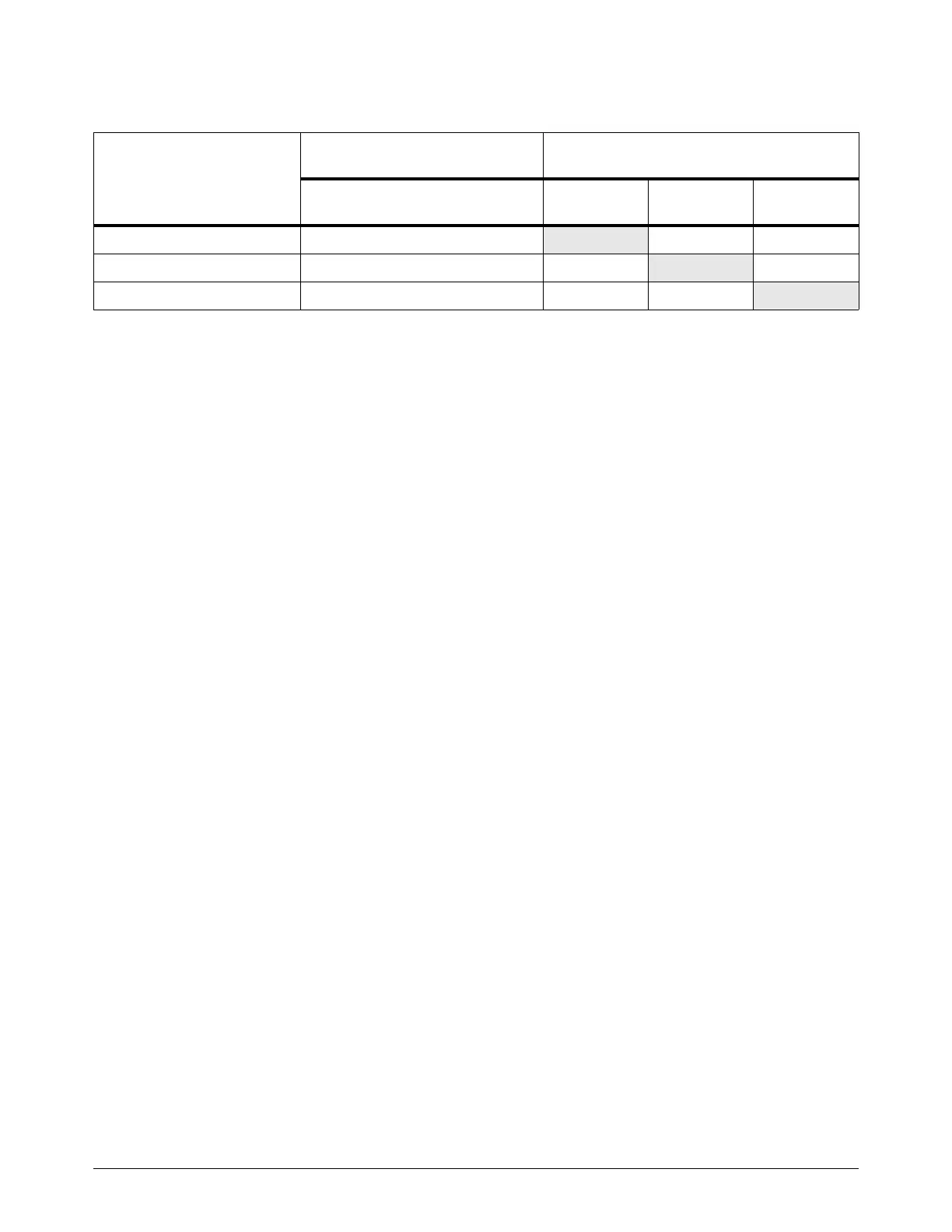

Table 23 – Communication requirements and options

* The device that first sets a process controls the plasma power supply. For information on how to change

the device that has control of the plasma power supply, refer to How to change the device that has control on

page 192.

** Discrete inputs are ignored when a process ID is set over EtherCAT to a cutting system that uses the

factory-default configuration. Contact your cutting machine supplier or Hypertherm Technical Service team

with questions.

Example: If you use EtherCAT to set the process, the preferred method to monitor is EtherCAT.

However, you can use RS-422 or the XPR web interface to monitor.

Set process with...*

To fully operate the cutting

system... Monitor with...

Discrete EtherCAT

XPR web

interface

RS-422

EtherCAT Can be required**

Preferred Alternative Alternative

XPR web interface Required Alternative

Preferred Alternative

RS-422 Required Alternative Alternative

Preferred

Loading...

Loading...