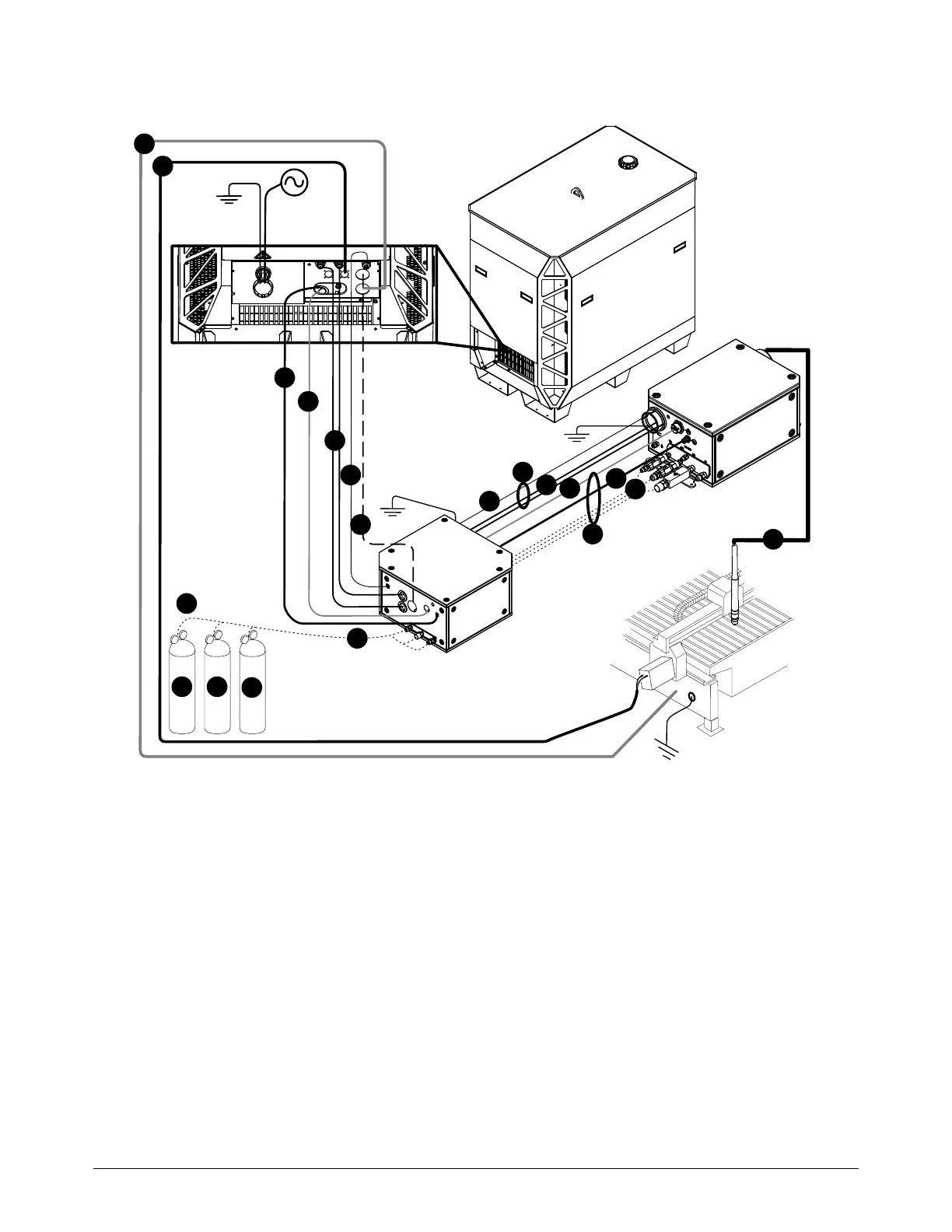

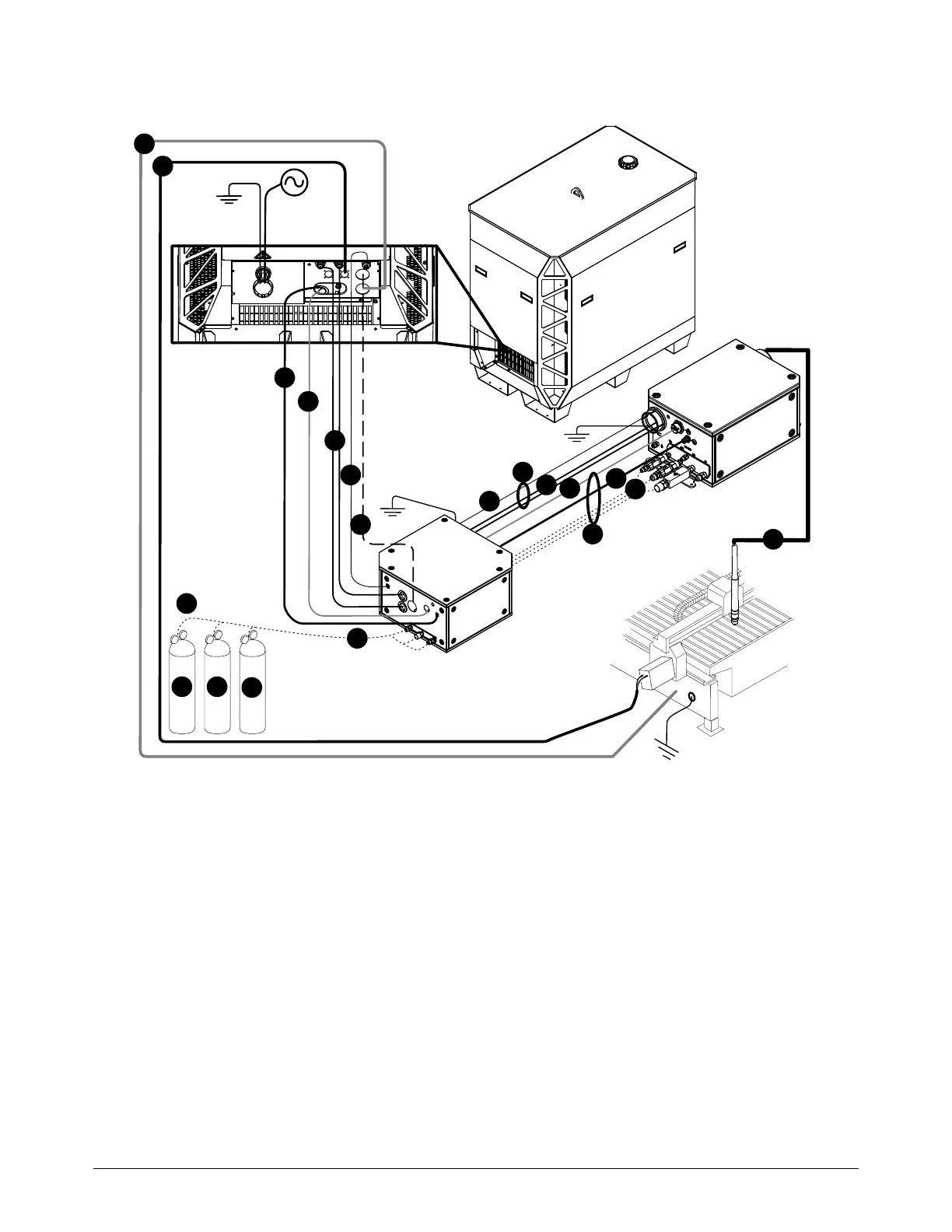

1 Work lead

2 CNC connection cable (EtherCAT shown)

3 Controller area network (CAN) cable

4 Power cable (120 VAC)

5 Coolant hose set (1 supply, 1 return)

6 Pilot arc lead

7 Negative lead (2/0 or 4/0)

8 Pilot arc and coolant hose set assembly

a Pilot arc lead

b Coolant hose set (1 supply, 1 return)

9 Power, CAN, 3-gas assembly

c Power cable (120 VAC)

d CAN cable

e 3 gas hoses (Core)

10 Torch lead

11 Hoses for supply gases

* Regulator

Position a gas regulator within 3 meters (10 feet)

of the gas connect console or take actions to

adjust inlet gas pressures to tolerances specified

in the process gas requirements.

Loading...

Loading...