Qualifications and Requirements

XPR300 Instruction Manual 809480 51

Shield water requirements (VWI and OptiMix)

If you use water as a shield fluid, refer to Table 9 for water pressure and flow requirements and Table

10 for water-purity guidelines.

If using shield water, the temperature range for cutting system operation

and storage is reduced to above 0°C to 40°C (32°F to 104°F).

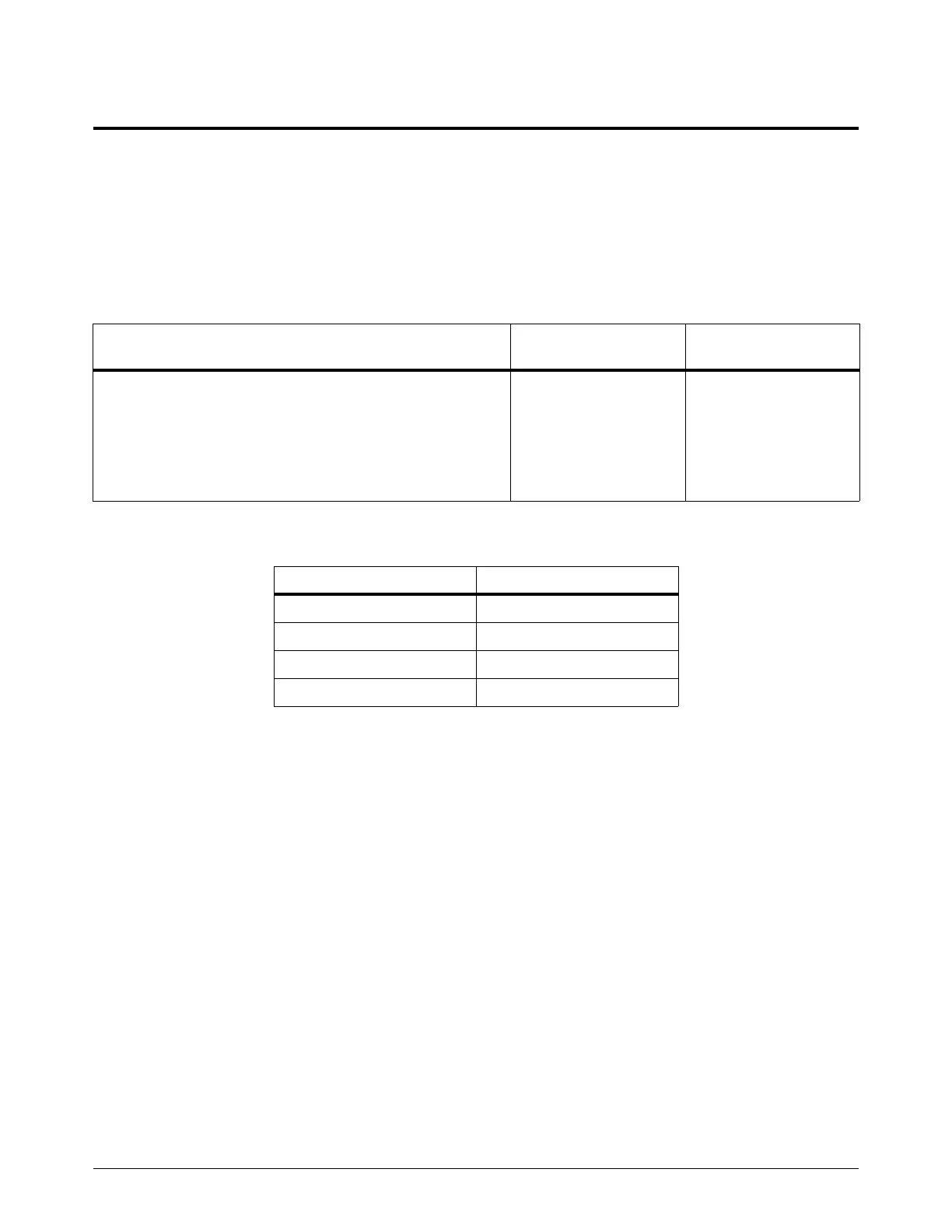

Table 9 – Quality, pressure, and flow requirements for shield water

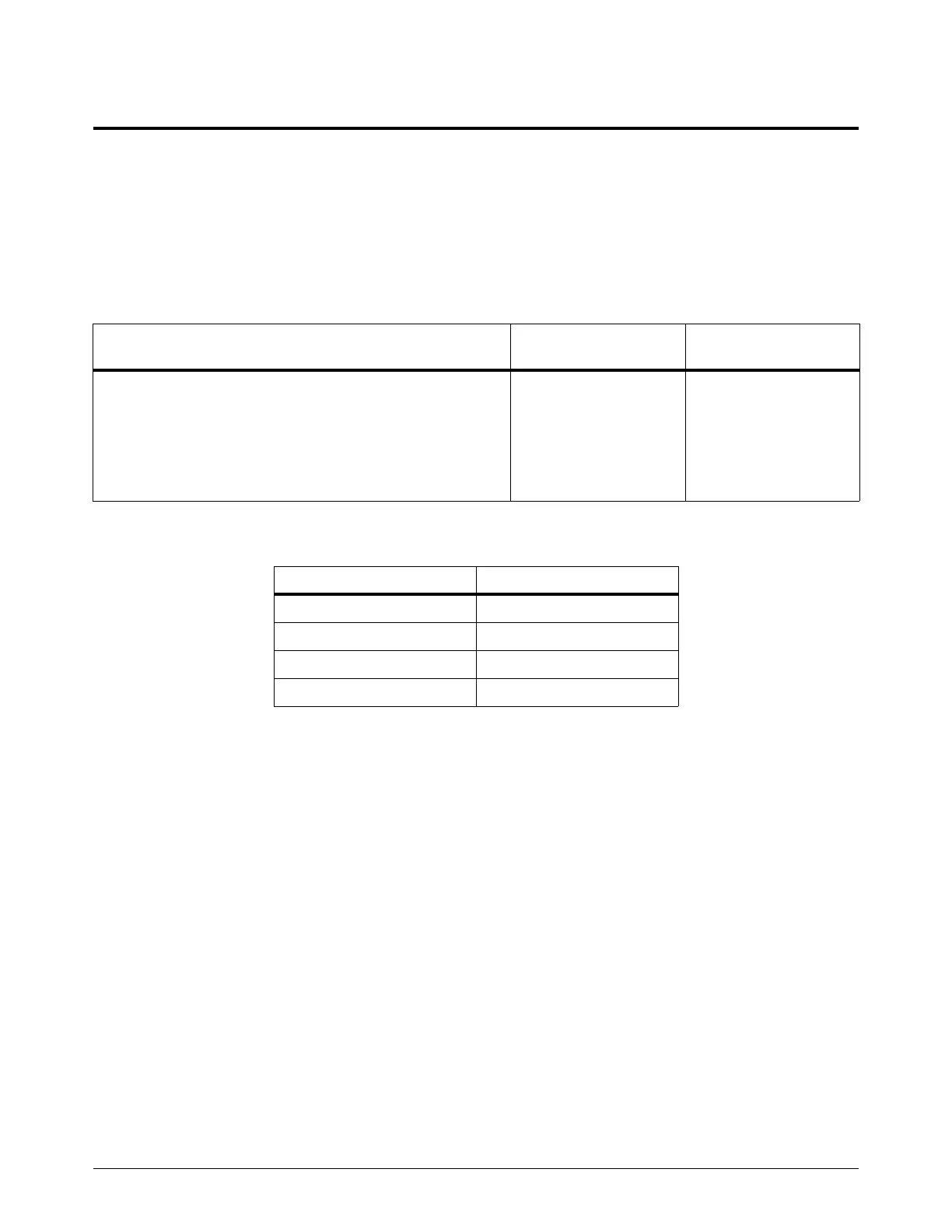

Table 10 – Purity requirements for shield water

A TDS meter indicates the Total Dissolved Solids (TDS) of a solution.

Dissolved ionized solids (such as salts and minerals) increase the

electrical conductivity of a solution. Total dissolved solids can be tested

with a TDS meter (Hypertherm Waterjet part number 1-13897) available

from Hypertherm.

* Water that does not meet minimum purity specifications can cause excessive deposits on the torch nozzle

and shield. These deposits can alter the water flow and produce an unstable arc. Refer to Shield water

requirements (VWI and OptiMix) on page 51.

Quality*

Minimum and

maximum pressure

Flow rate required

Deionized water is not recommended to use as shield water.

Deionized water will react with the copper components in the

system and result in decreased life of components and

consumables.

Hypertherm recommends that you contact a water-quality

expert for guidance.

2.76 bar (40 psi)

minimum

8.27 bar (120 psi)

maximum

35 L/h (9.4 US gal/h)

Particulate type Purity requirement

Total dissolved solids < 61 PPM

Calcium + magnesium < 40 PPM

Silica < 5 PPM

pH 6.5 – 8.0

Loading...

Loading...