8.6 How to replace components

8-33

8. Maintenance and Inspection

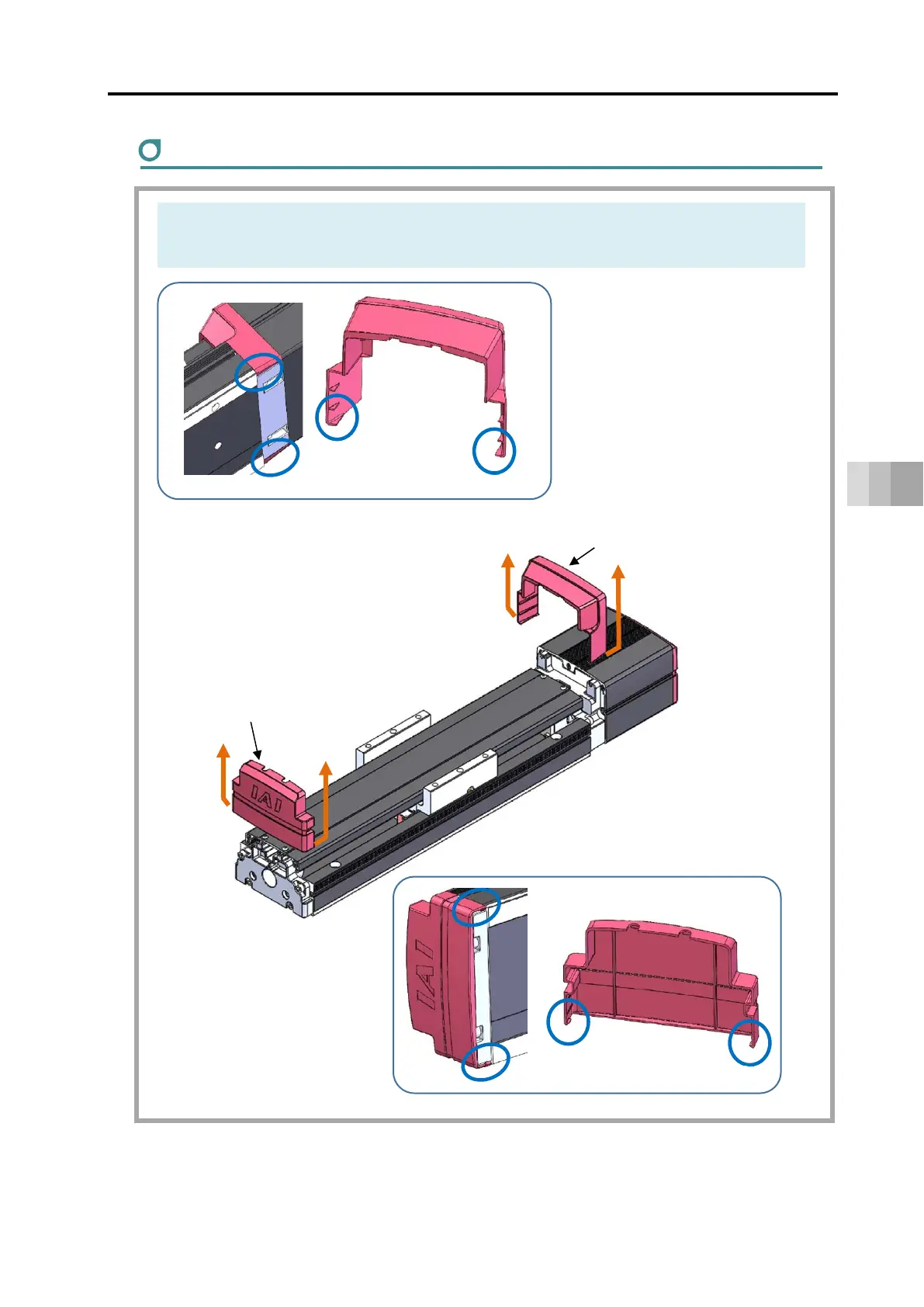

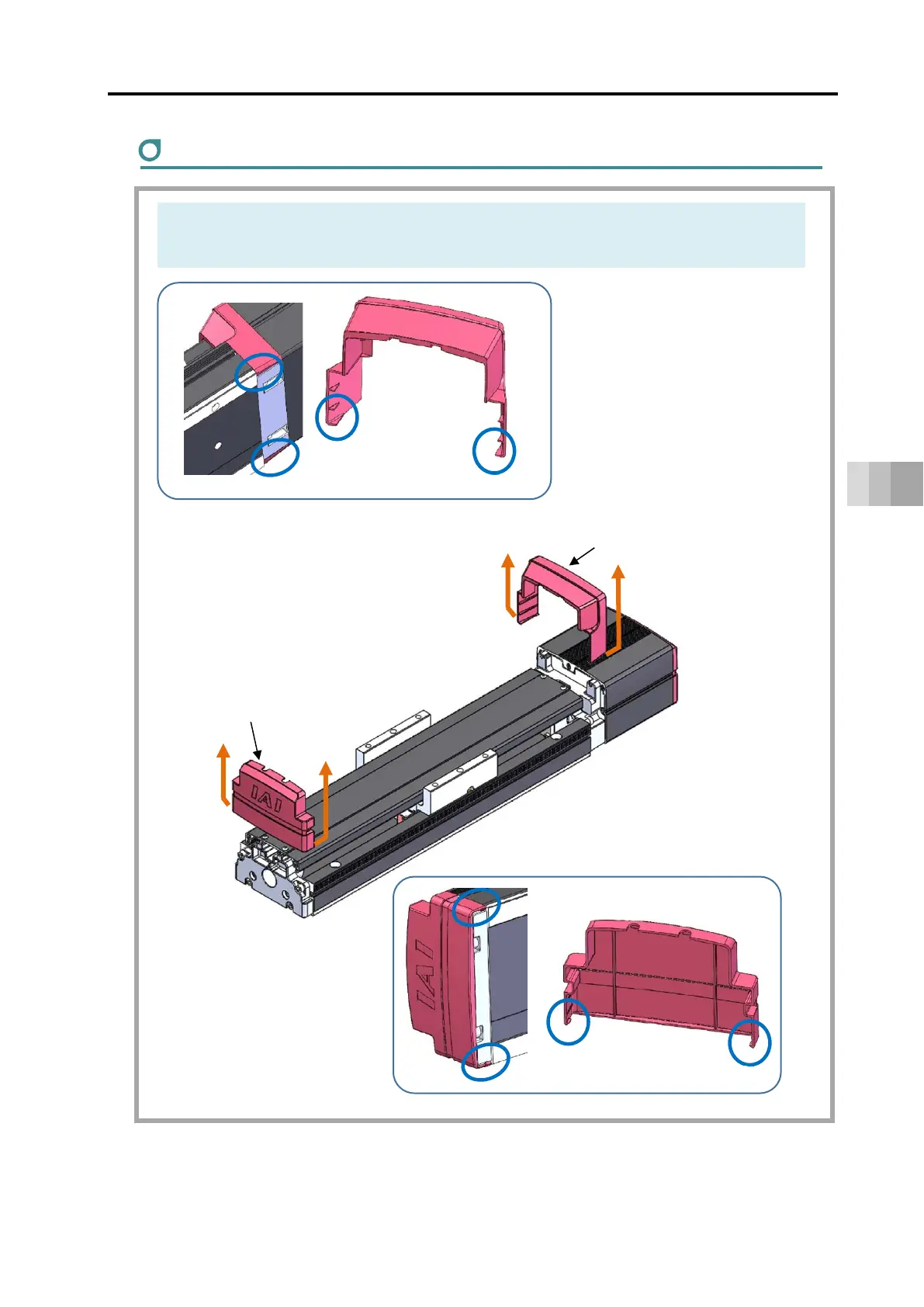

Replacement of intermediate support cushion

1) In order to take off the front bracket cover and rear bracket cover, open them up to

the outer side and pull them up.

Front bracket cover

Rear bracket cover

Hooks on base seating surface

Hooks on base seating surface

Loading...

Loading...