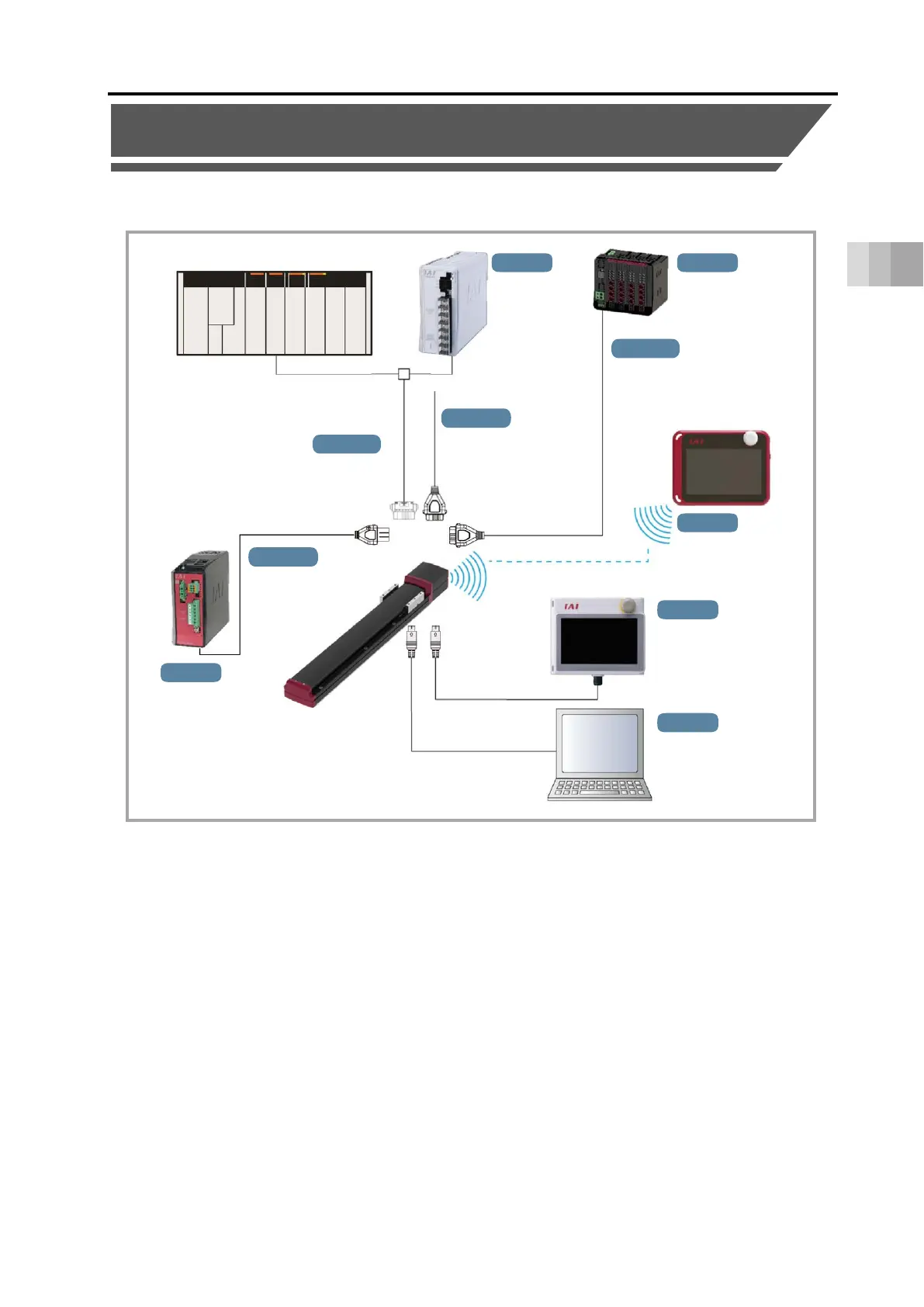

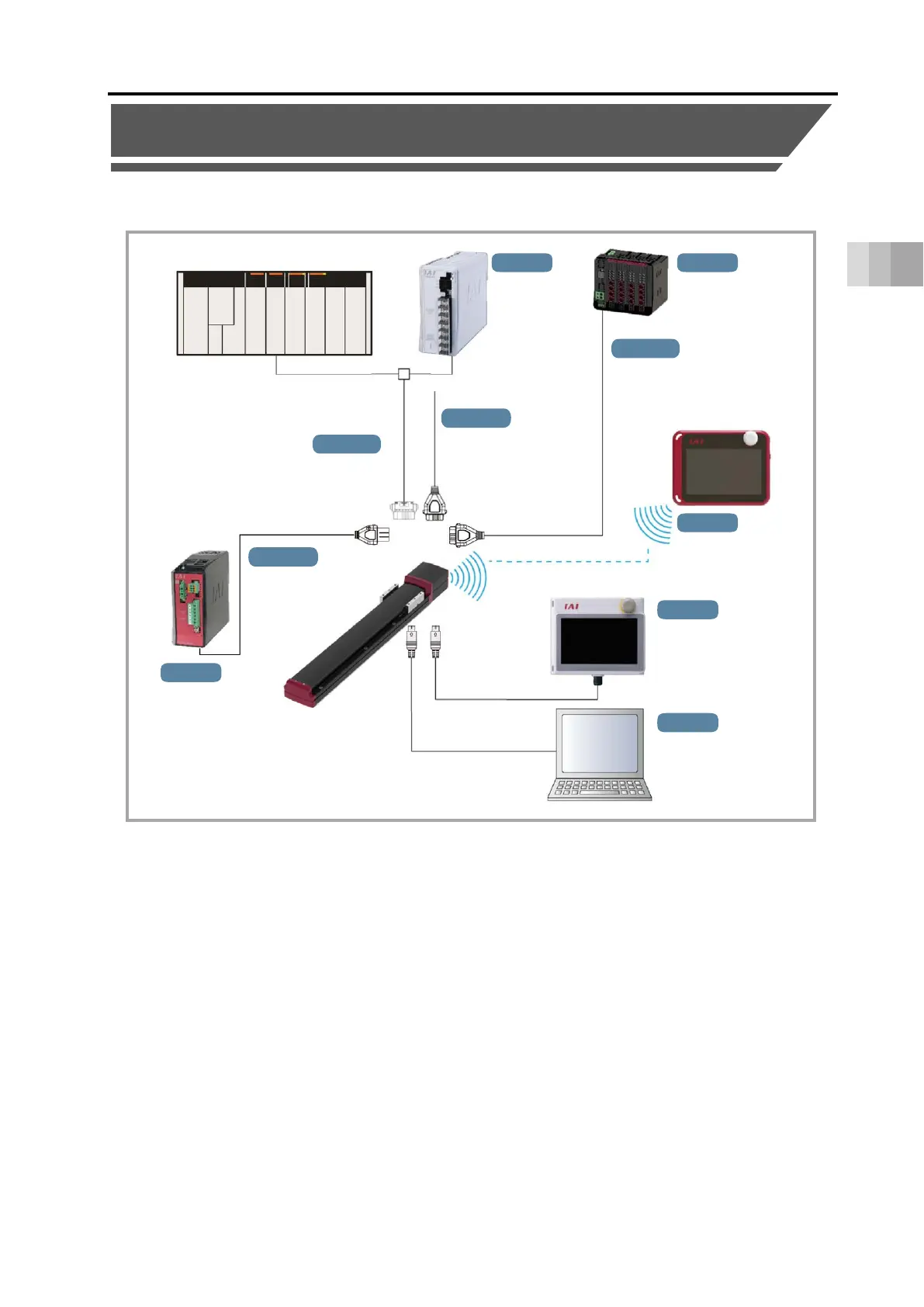

3.1 System configuration

3-1

3. Wiring

PLC

Accessories

Accessories

Accessories

Accessories

Option

Option Option

Option

Option

Option

Motor drive

DC power supply PSA-200

<Model: PSA-200-□>

It generates power of drive

200 V.

* Six axis at the maximum of

ELECYLINDER can be

connected in the maximum

connectable motor wattage.

Motor power supply cable

<Model: CB-EC-PW□□□-RB>

It is a cable to supply the

drive 200 V power to an

actuator.

Power / I/O connector

Connector for connecting customer-side

power wiring.

<Model: 1-1871940-6>

<Wires>

For “24 V” and “0 V” , the thickness should be AWG18.

For others, it should be AWG26 or higher.

* All cables should be 10 m or shoter.

Power / I/O cable

<Model: CB-EC-PWBIO□□□-RB>

Cable for connecting power and

PLC I/O signals.

24 V DC

power supply

<Model: PSA-24>

EC connection unit

<Model: REC-GW-□

+ RCON-EC-4>

It is a unit to connect to

field network.

Power supply / communication cable

<Model: CB-EC-REC□□□-RB>

Cable for connecting actuator and

EC connection unit.

Touch Panel

Teaching Pendant

<Model: TB-03-□>

Touch Panel

Teaching Pendant

<Model: TB-02-□>

PC software

Only software

<Model: IA-OS>

Equipped with dedicated

connection cable

<Model: IA-OS-C>

Dedicated connection cable

3.1 System configuration

The following shows the system configuration.

By supplying 24 V DC to ELECYLINDER and 200 V AC (or 100 V AC) to the drive 200 V power

supply, ELECYLINDER can be operated with signals from the host device input to

ELECYLINDER.

This manual introduces an example using a PLC connected as the master device.

Loading...

Loading...