7 - BAR FEEDER MAINTENANCE BOSS 332/545/552 HD

EN

7 - Pag. 3 / 8

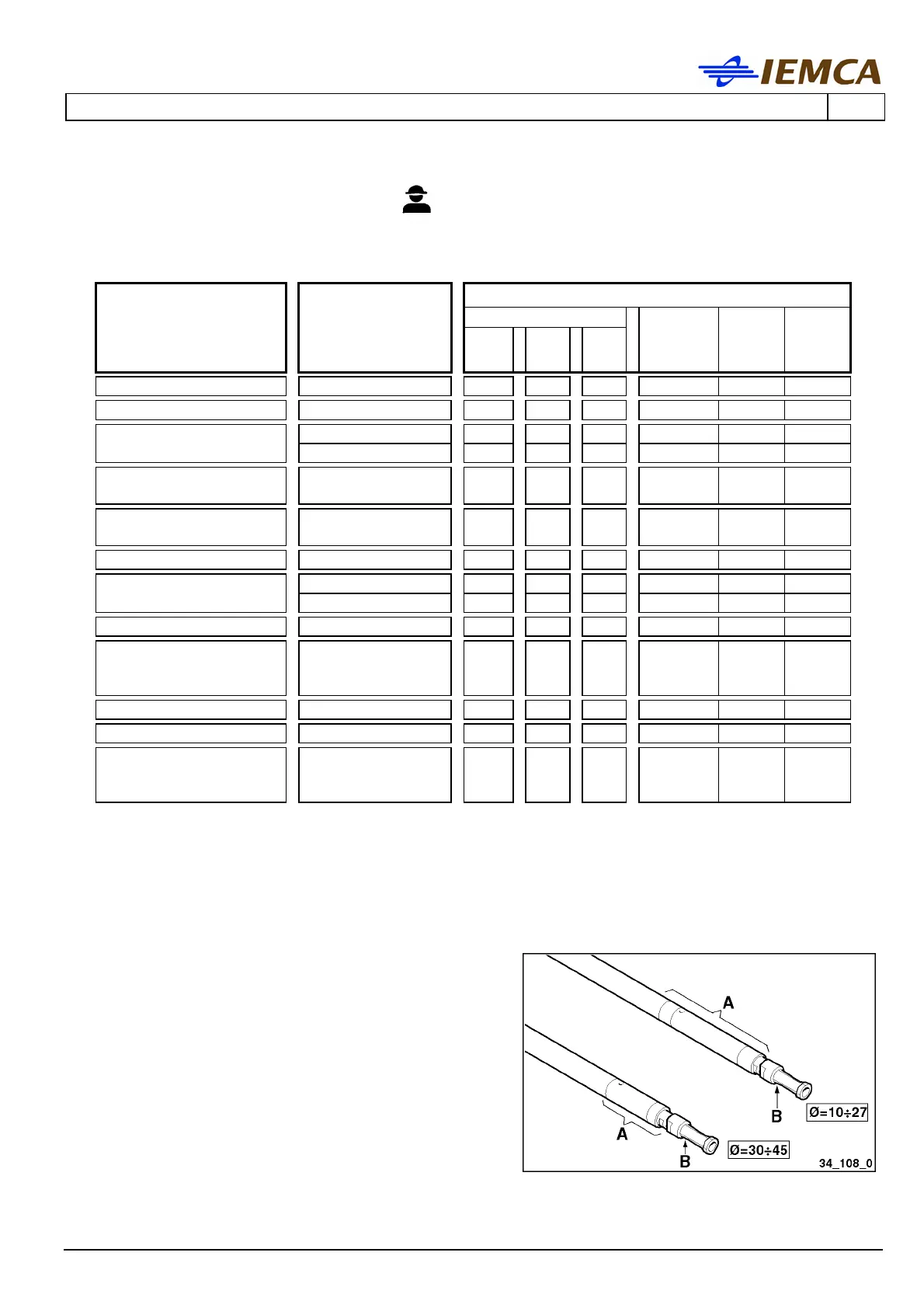

7.2 SCHEDULED MAINTENANCE

Scheduled maintenance

Frequency

Hours

Machine section

Operation to be

carried out

200 1250 2500

Regularl

y

Every

year

Cycles

Revolving tip and collet Wear check •

Half bushes Wear check •

Oil level check •

Lubrication system

Oil change •

Guide channels Integrity and

cleanness check

•

Guide channel opening

screw

Greasing •

Oil recovery device brush Wear check •

Lubrication •

Feeding chain

Tensioning check •

Guide channel opening belt Wear check •

Bar - headstock

synchronization device belt

(*)

Wear check

5000

Air filter Check •

PLC battery Replacement •

Safety devices Check the efficiency

(see “Safety

devices”)

•

(*) Only if installed.

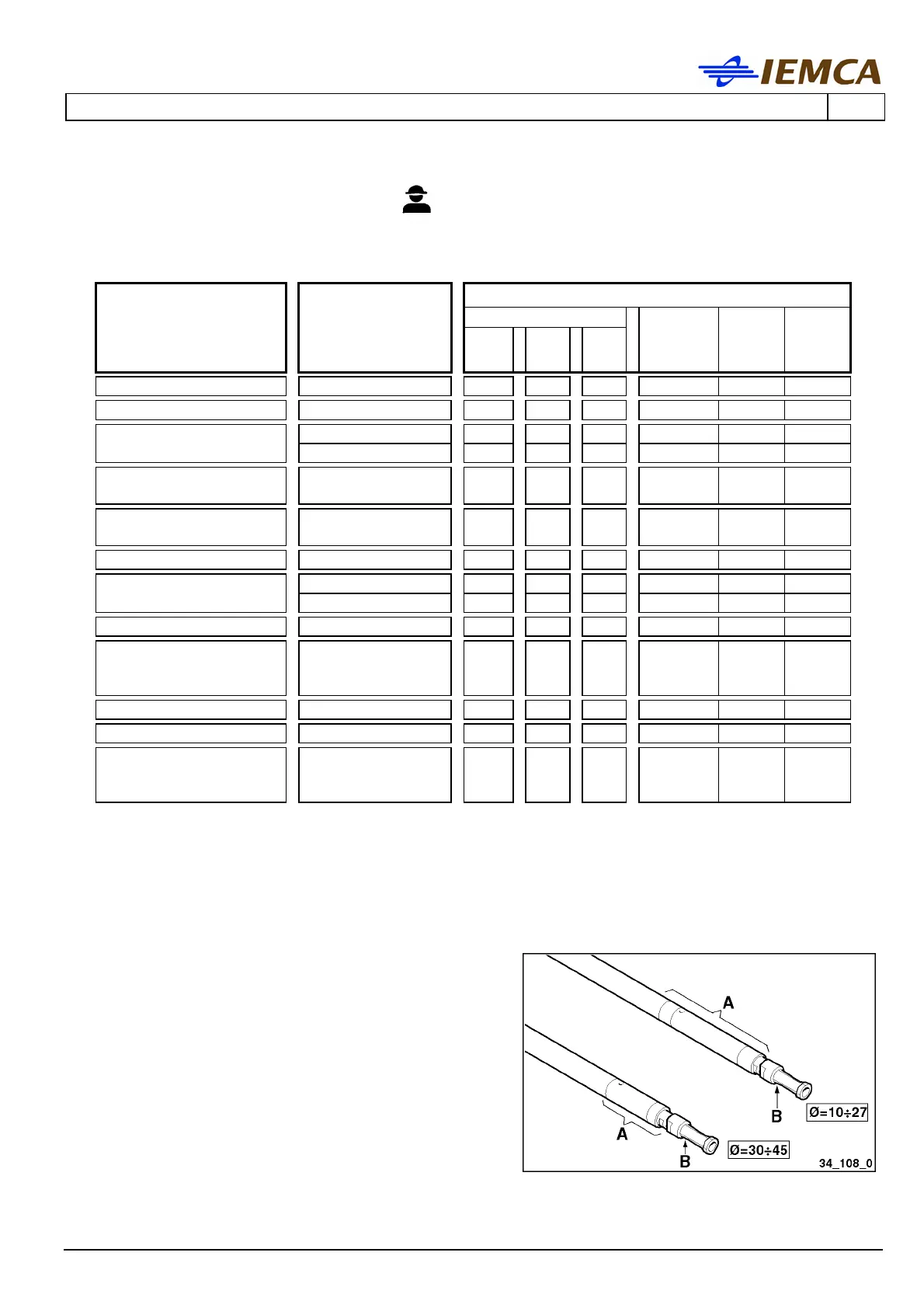

7.2.1 Revolving tip and collet - Check

• Remove the bar pusher, as described in section

"GUIDE CHANNELS, HALF BUSHES, BAR PUSHER

AND COLLET - REPLACEMENT", CH. 5.

• Check that the revolving tip "A" can turn freely

without excessive backlash.

Also check the good state of repair of collet "B".

Loading...

Loading...