2 - TECHNICAL INFORMATION BOSS 332/545/552 HD

EN

2 - Pag. 3 / 32

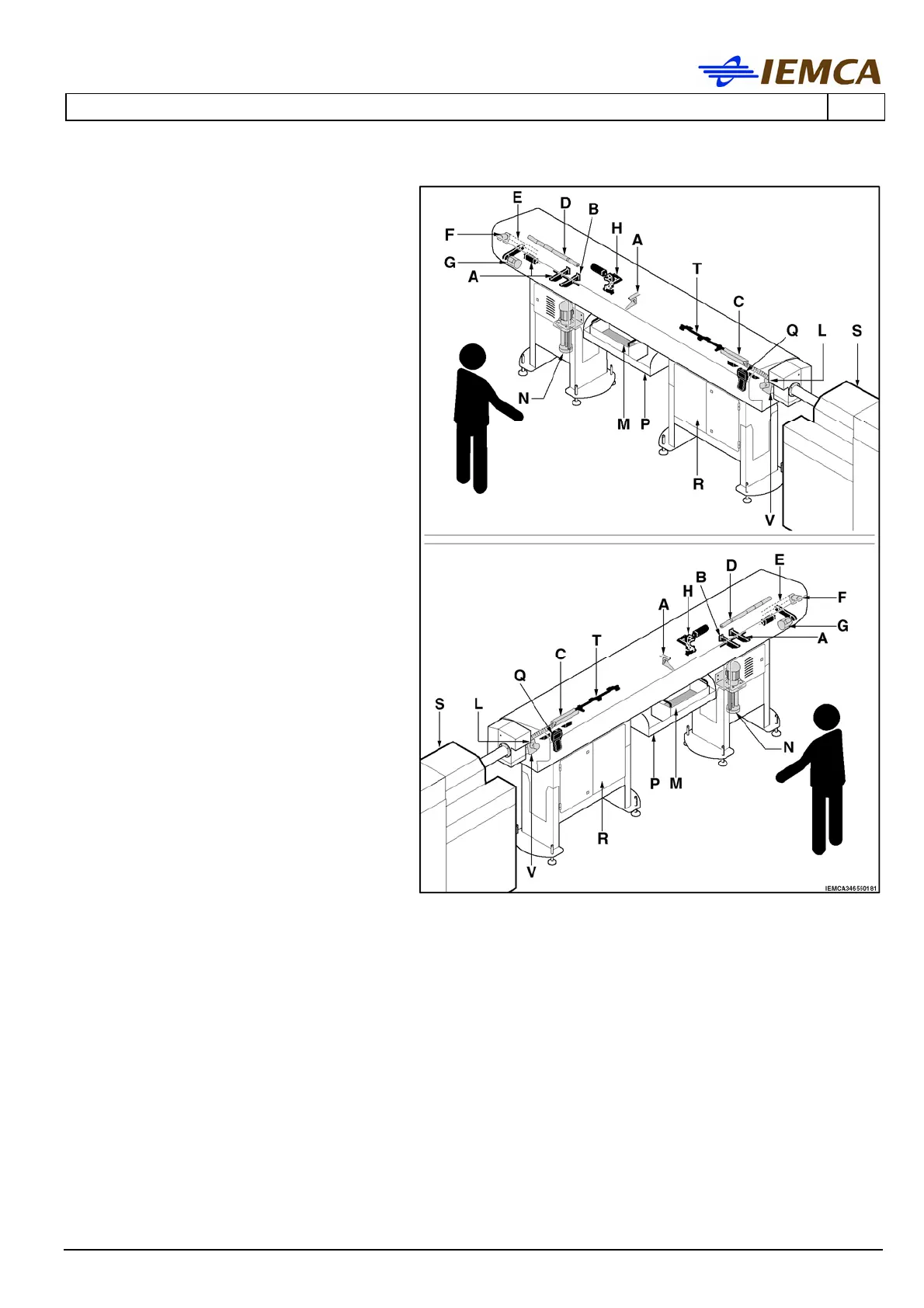

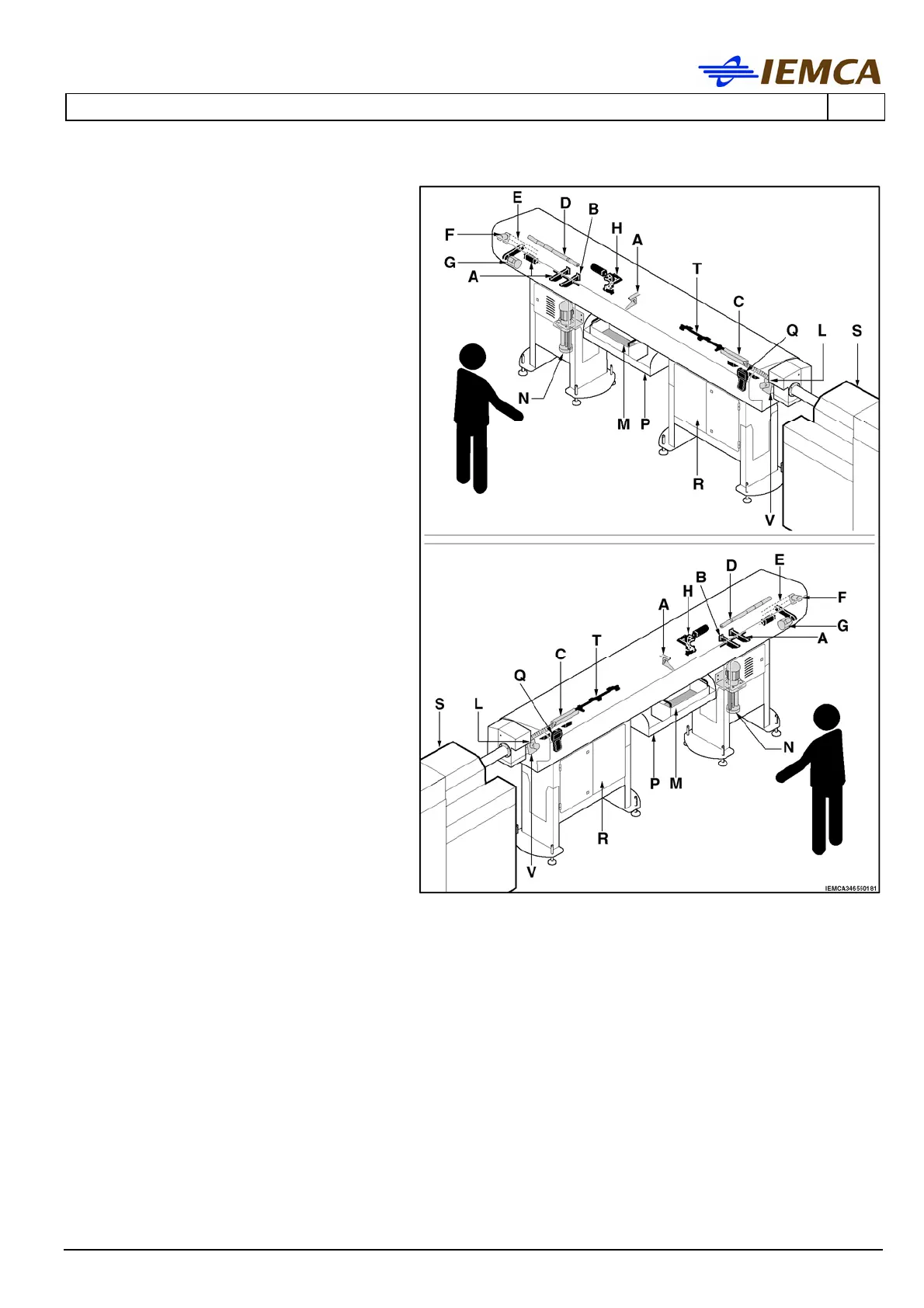

• MAIN PARTS

A MAGAZINE; it stores the bars.

B BAR SELECTION DEVICE; it enables

the first bar to be lowered into the

guide channels and holds the

remaining bars in the magazine.

C GUIDE CHANNELS; they guide the

bars during machining.

D BAR PUSHER; it pushes the bar

during machining.

E FEED CHAIN; transmits the motion

from the motor drive to the bar

pusher.

F DRIVE SYSTEM; it moves the bar

pusher.

G FEEDING- REMOVAL DRIVE; it drives

the bar feeder parts that control bar

feeding into the collet and

subsequent bar remnant removal. It

also drives the bar feeder parts that

control guide channel

opening/closing and bar selection.

H CLAMPS; they hold the bar during

loading and removal from the collet

of the bar pusher.

L FACING DEVICE; it sends a signal

when the bar passes.

M REMNANT RECOVERY BOX; bar

remnants are dropped into this box

after removal from the bar pusher

collet.

N LUBRICATION PUMP; it delivers oil to

the guide channels.

P OIL RECOVERY DEVICE; it collects oil

flowing out of the guide channels.

Q HANDHELD KEYBOARD; it allows bar feeder programming and function activation.

R ELECTRIC CABINET; it houses the electrical control panel.

S LATHE

T GUIDE CHANNEL OPENING SHAFT

V ENCODER

Loading...

Loading...