5 - ADJUSTMENTS AND SETTING-UP BOSS 332/545/552 HD

EN

5 - Pag. 3 / 34

5.2 GENERAL ADJUSTMENTS - FOREWORD

All the necessary adjustments for correct bar feeder operation are included. They may become

necessary for maintenance, troubleshooting or component replacement.

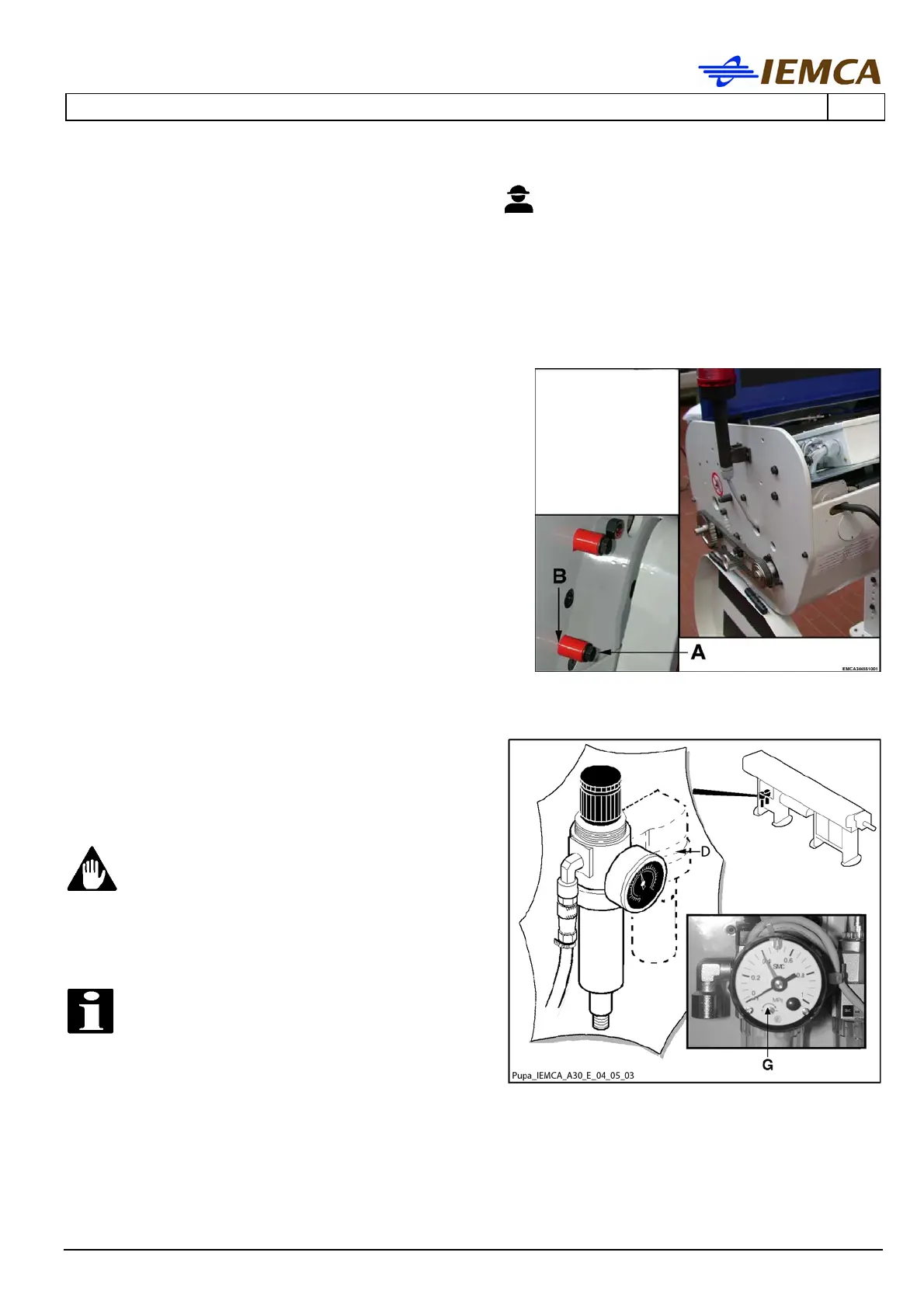

5.2.1 Feeding chain - Adjustment

For the movement chain of the bar pusher, tension

screws A on the rear plate of bar feeder is provided.

After some bar feeder operating hours, the chain

tension has to be checked.

• If bush B of chain tension is still fastened to the

rear plate, then no chain extension took place.

• On the contrary, if bush B moved away by1- 2 mm

from rear plate, then a chain extension took place,

which is dangerous for correct operation of bar

feeder. Screw A must then be tightened until bush

B is fastened to the rear plate.

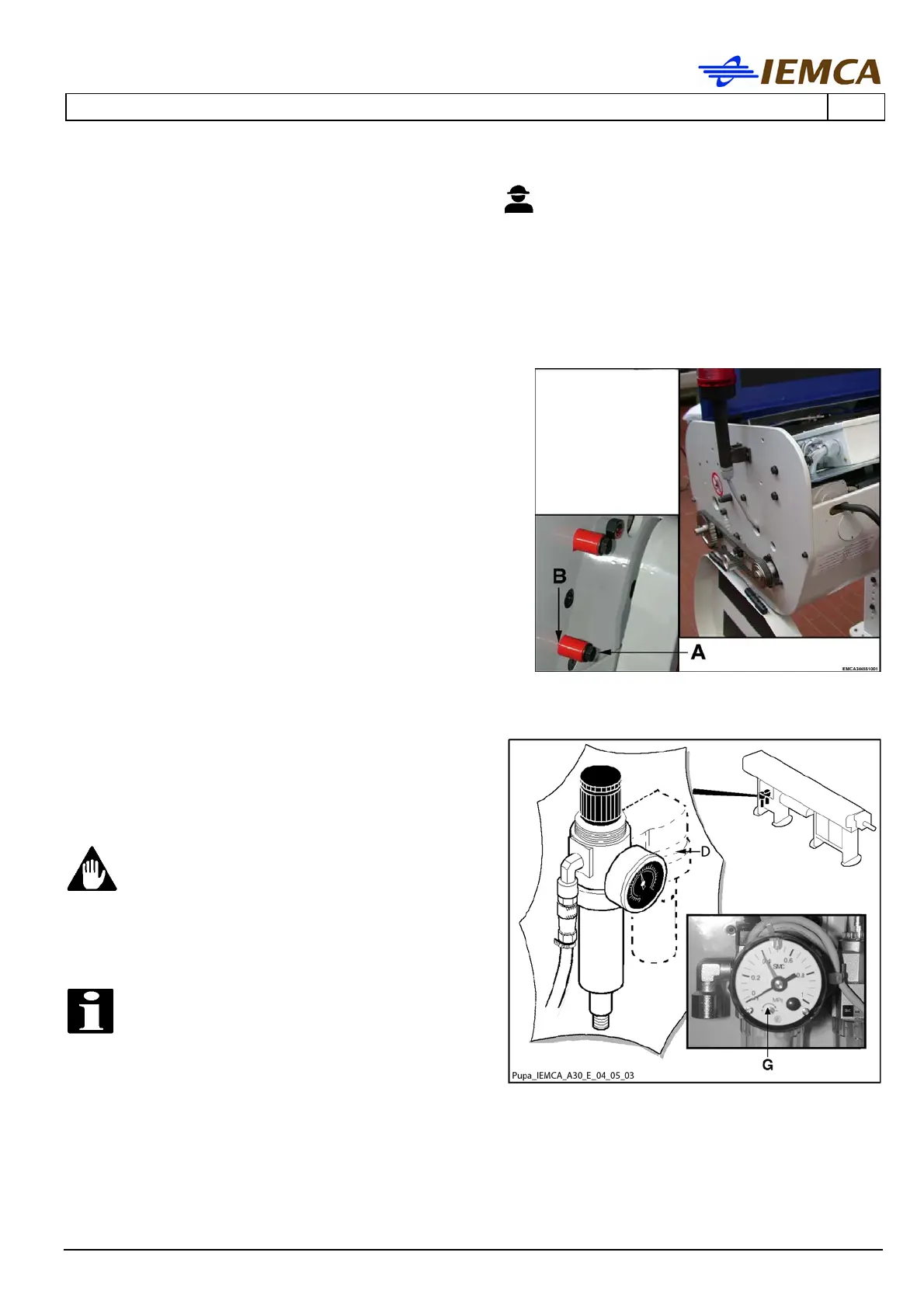

5.2.2 Air adjusting unit - Adjustment

After unscrewing the glass protection, the

pressure switch can be properly adjusted by

turning the relevant adjusting screw (G). Proper

setting is 4.5 bars (0.45 MPa).

WARNING – CAUTION:

Do not further turn anticlockwise when

the green pointer is on 0, as this may

cause damage to the pressure switch.

INFORMATION:

Lubricator D is fitted only when the

headstock synchronization device is

assembled.

Loading...

Loading...