9 | Software Operation INFICON

164 / 319 074-594-P1H Micro GC Fusion Operating Man-

ual

The number of module tabs is dependent on the instrument configuration. In a

2-module Micro GC Fusion system, either one or two module tabs

(corresponding to Module A and Module B, if configured) will be present. In a

4-module Micro GC Fusion system, either three or four module tabs

(corresponding to Module A, Module B, Module C and Module D, if configured)

will be present.

To display the module injector, column, and detector information, hover the

mouse over the icon next to the corresponding Module tab.

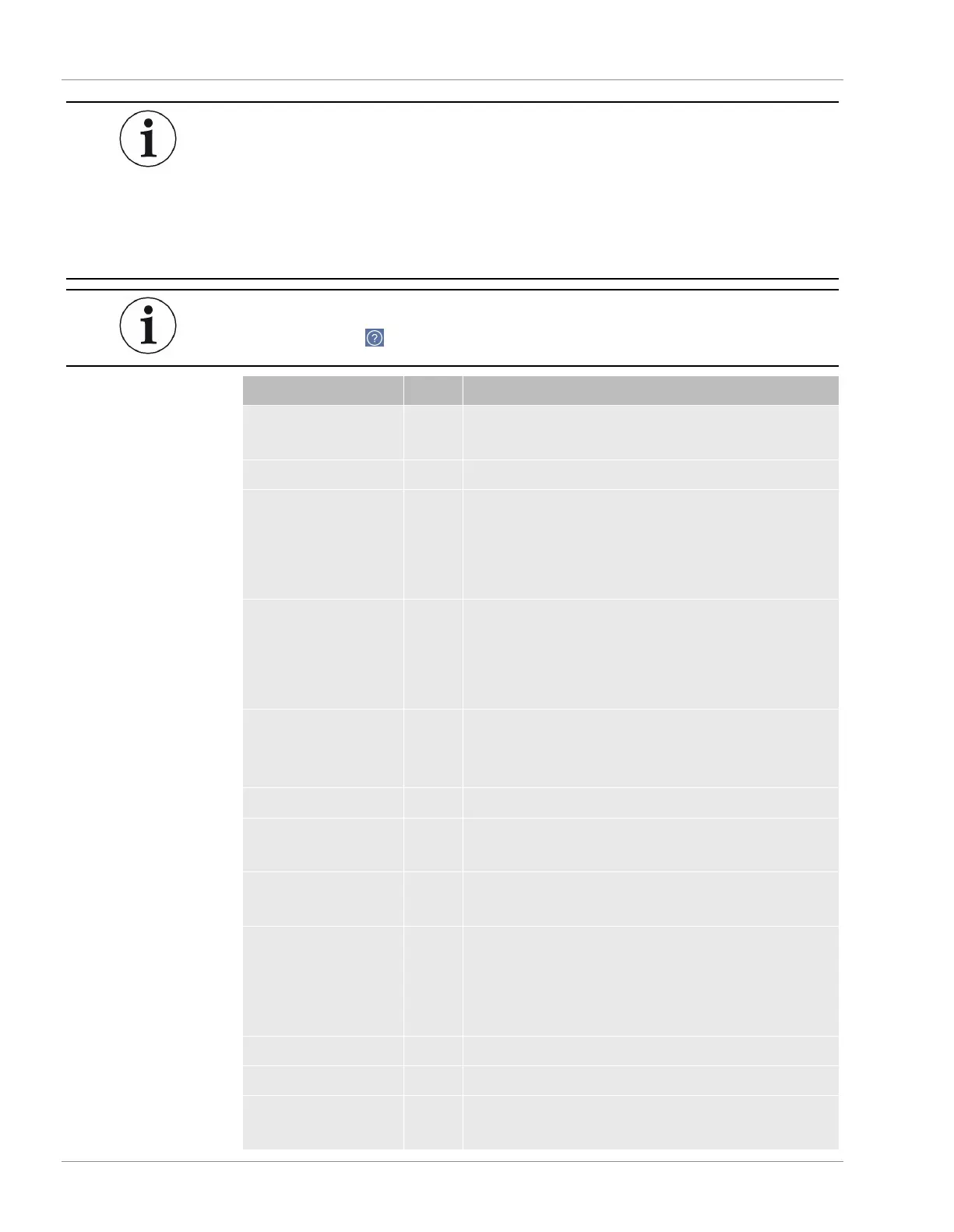

Method Parameter Unit Description

Inject (ms) ms Duration the injector valve is open to allow sample to

enter the column

Injector °C Temperature of the injector

Enhanced inject N/A Changes the injection pressure to increase peak

area and height for low level components.

NOTE: Not available with backflush or fixed volume

injectors.

Injection pressure psi The additional pressure for enhanced injections. This

parameter can be set between10 to 50, or disabled.

NOTE: Not available with backflush or fixed volume

injectors.

Backflush time (if

configured)

s Time between sample injection and injector

backflush action to vent undesired compounds from

the pre-column

TCD °C Temperature of the TCD

TCD delta °C The amount the TCD is allowed to vary before

becoming "Ready." Can be set up to 50°C

Column pressure psi (or

kPa)

Carrier gas pressure applied at the column head to

direct sample gas into the analytical column.

Data rate Hz Detector signal data points per second

Note: For optimal separation on the Rt-Q-Bond and

Rt-Alumina columns, use a data rate of 100 Hz or

greater.

Ramp rate °C/s Temperature ramp rate of analytical column

Column temperature °C Temperature set point(s) of the analytical column

Hold time s Duration the column remains at the desired

temperature

Loading...

Loading...