52 EasyCoder PX4i and PX6i Service Manual

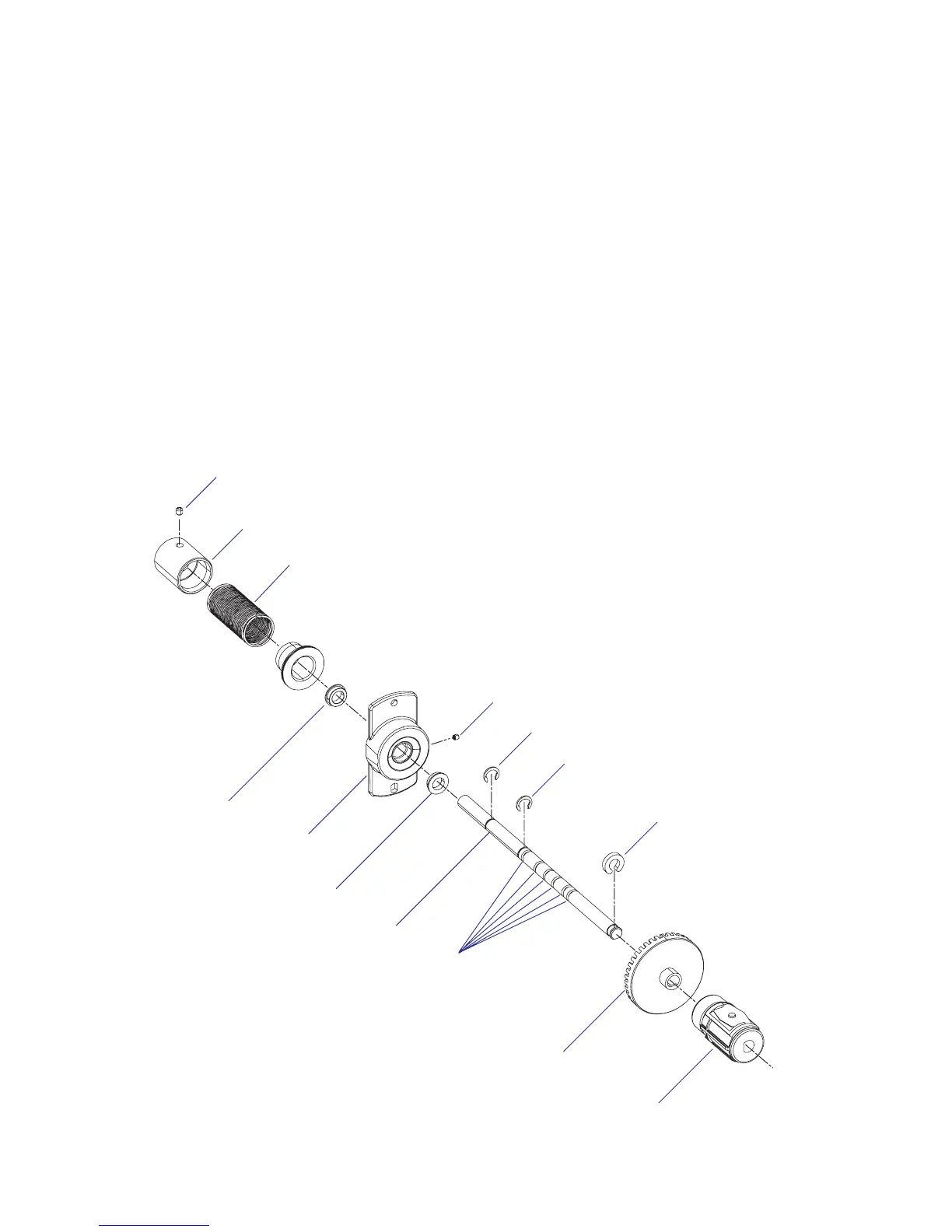

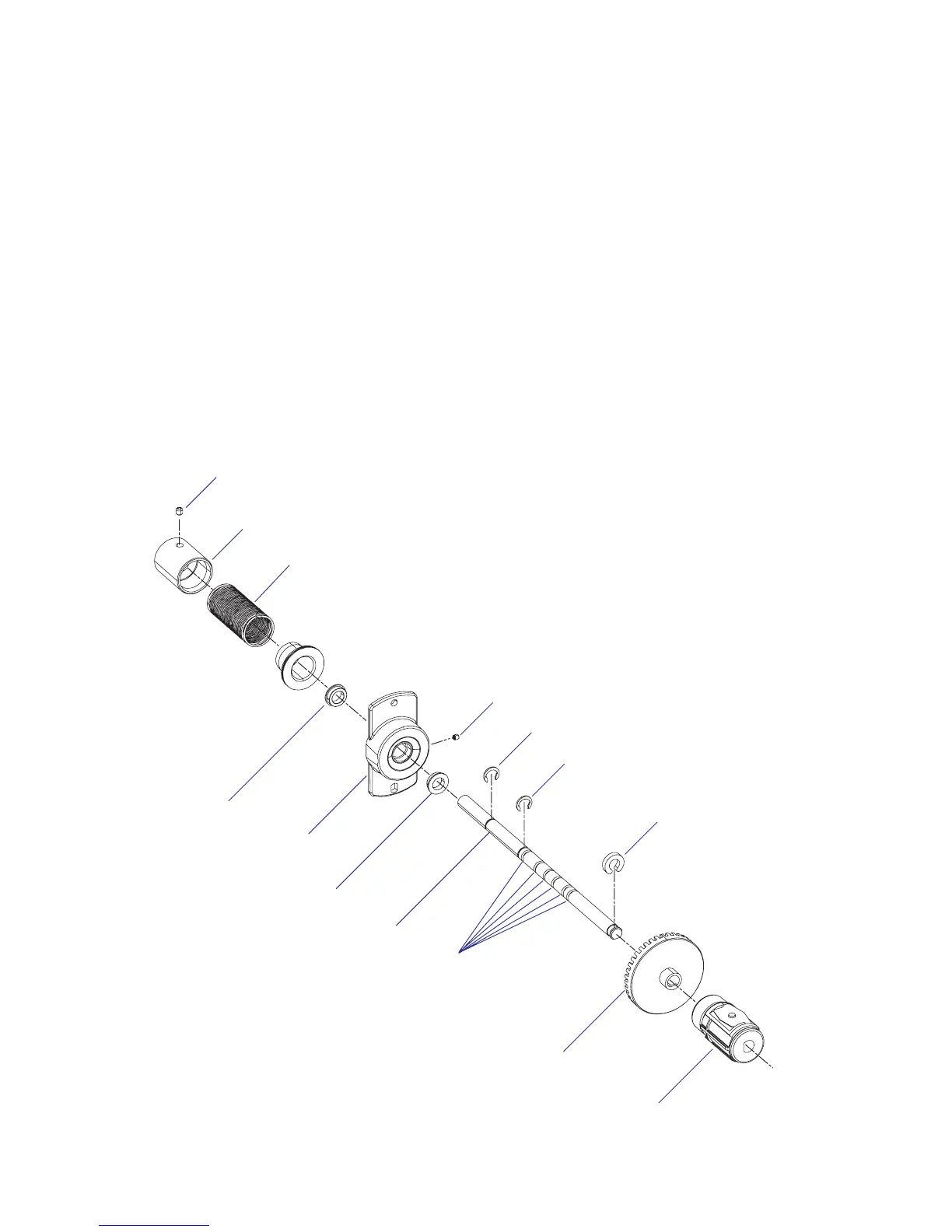

Chapter 7 — Transfer Ribbon Mechanism

Working Principles

The ribbon supply is braked by a spring affi xed to the printer’s center sec-

tion, partly enveloped by a sleeve affi xed to the shaft. Initially, the spring

expands towards the inner wall of the sleeve, thereby breaking the rotation

of the shaft. When the bobbin is forced to rotate (that is, when the ribbon

is unwound), the breaking spring is compressed. After approximately half

a turn, the diameter of the spring has been compressed enough to allow

the sleeve to slip. The brake torque should be 55 ±5 Nmm (see Appendix

C). The sleeve is fi lled with ball bearing grease. If the brake torque deviates

from the recommended value, replace the grease. We recommend Castrol

Sinplex 2. The expected interval between replacing the grease is 8 to 10

million print cycles.

When the rotating force ceases, the spring tends to pull back the ribbon,

keeping it tight.

Pivot assy.

Brake sleeve

Grub screw

Locking washer

Torque spring

(diff ers between

models)

Ball bearing

Flange

Shaft

Grooves

Grub screw

Fixing ring

Code disc

Ball bearing

Locking washer

Loading...

Loading...